What is Global CNC Vertical Machining Centers Market?

The Global CNC Vertical Machining Centers Market refers to the worldwide industry focused on the production, distribution, and utilization of CNC (Computer Numerical Control) vertical machining centers. These machines are essential in the manufacturing sector as they automate the process of cutting, drilling, and shaping materials like metal, plastic, and wood. The vertical machining centers are characterized by their vertical spindle orientation, which allows for efficient and precise machining of complex parts. This market is driven by the increasing demand for high-precision components across various industries such as automotive, aerospace, and metal fabrication. Technological advancements in CNC systems, which enhance the efficiency and accuracy of machining processes, further propel the market's growth. Additionally, the integration of IoT and AI in CNC machines is revolutionizing the industry by enabling real-time monitoring and predictive maintenance, thus reducing downtime and operational costs. The global market is highly competitive, with numerous players striving to innovate and offer advanced solutions to meet the evolving needs of end-users. As industries continue to seek automation and precision in manufacturing processes, the demand for CNC vertical machining centers is expected to rise steadily.

Less Than 5-Axis, 5-Axis, More Than 5-Axis in the Global CNC Vertical Machining Centers Market:

In the Global CNC Vertical Machining Centers Market, machines are categorized based on the number of axes they operate on: Less Than 5-Axis, 5-Axis, and More Than 5-Axis. Each category serves different purposes and offers varying levels of complexity and precision. Less Than 5-Axis machines, typically 3-axis or 4-axis, are the most common and are used for simpler machining tasks. These machines are ideal for operations that require less intricate detailing and are often employed in industries where basic cutting, drilling, and milling are sufficient. They are cost-effective and easier to program, making them suitable for small to medium-sized enterprises that do not require high-end precision. On the other hand, 5-Axis machines are more advanced and versatile, capable of machining complex parts with intricate geometries. The additional axes allow for simultaneous movement, enabling the machine to approach the workpiece from multiple angles. This capability is crucial in industries like aerospace and automotive, where precision and complexity are paramount. 5-Axis machines reduce the need for multiple setups, thereby increasing efficiency and reducing production time. They are also beneficial in reducing the risk of human error, as the machine can complete tasks that would otherwise require manual intervention. More Than 5-Axis machines, such as 6-axis or 7-axis, offer even greater flexibility and precision. These machines are used for the most complex and demanding applications, often in high-tech industries that require the utmost accuracy and detail. The additional axes provide more freedom of movement, allowing for the creation of intricate parts that would be impossible to achieve with fewer axes. These machines are typically used in specialized applications, such as the production of aerospace components, medical devices, and intricate molds. While they offer unparalleled precision and capability, More Than 5-Axis machines are also the most expensive and require skilled operators to program and maintain. The choice between these categories depends on the specific needs of the industry and the complexity of the parts being produced. As technology continues to advance, the capabilities of CNC vertical machining centers are expected to expand, offering even more options for manufacturers seeking to enhance their production processes.

Automotive Industry, Aerospace Industry, Metal Fabrication Industry, Others in the Global CNC Vertical Machining Centers Market:

The Global CNC Vertical Machining Centers Market finds extensive usage across various industries, each benefiting from the precision and efficiency these machines offer. In the automotive industry, CNC vertical machining centers are crucial for manufacturing engine components, transmission parts, and other critical elements that require high precision and consistency. The ability to produce complex geometries with tight tolerances ensures that automotive parts meet stringent quality standards, enhancing vehicle performance and safety. Additionally, the automation capabilities of CNC machines reduce production time and costs, allowing automotive manufacturers to remain competitive in a fast-paced market. In the aerospace industry, the demand for CNC vertical machining centers is driven by the need for lightweight, high-strength components that can withstand extreme conditions. These machines are used to produce parts such as turbine blades, structural components, and landing gear, where precision and reliability are paramount. The ability to machine complex shapes with minimal manual intervention reduces the risk of errors and ensures that aerospace components meet rigorous safety and performance standards. The metal fabrication industry also relies heavily on CNC vertical machining centers for cutting, shaping, and assembling metal parts. These machines offer the flexibility to handle a wide range of materials and thicknesses, making them ideal for producing custom metal products. The precision and repeatability of CNC machining ensure that fabricated parts fit together seamlessly, reducing waste and improving overall product quality. Other industries, such as electronics, medical devices, and consumer goods, also benefit from the capabilities of CNC vertical machining centers. In electronics, these machines are used to produce intricate components for circuit boards and other devices, where precision is critical. In the medical field, CNC machining is essential for manufacturing surgical instruments, implants, and prosthetics, where accuracy and biocompatibility are crucial. The consumer goods industry uses CNC machines to produce a wide range of products, from household appliances to sporting equipment, where quality and consistency are key. Overall, the versatility and precision of CNC vertical machining centers make them indispensable across various sectors, driving innovation and efficiency in manufacturing processes.

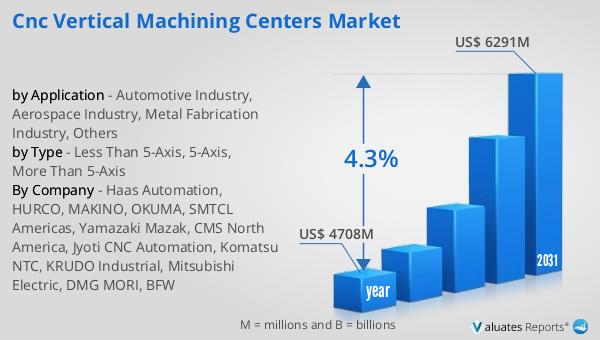

Global CNC Vertical Machining Centers Market Outlook:

The global market for CNC Vertical Machining Centers was valued at approximately $4.7 billion in 2024. It is anticipated to grow significantly, reaching an estimated size of $6.3 billion by 2031. This growth trajectory represents a compound annual growth rate (CAGR) of 4.3% over the forecast period. This upward trend is indicative of the increasing demand for precision machining solutions across various industries. The market's expansion is fueled by the continuous advancements in CNC technology, which enhance the efficiency and accuracy of machining processes. As industries strive for automation and precision in manufacturing, the adoption of CNC vertical machining centers is expected to rise. The integration of IoT and AI in these machines is also contributing to market growth by enabling real-time monitoring and predictive maintenance, thus reducing downtime and operational costs. The competitive landscape of the market is characterized by numerous players striving to innovate and offer advanced solutions to meet the evolving needs of end-users. As the demand for high-precision components continues to grow, the global CNC vertical machining centers market is poised for steady growth, offering significant opportunities for manufacturers and suppliers alike.

| Report Metric | Details |

| Report Name | CNC Vertical Machining Centers Market |

| Accounted market size in year | US$ 4708 million |

| Forecasted market size in 2031 | US$ 6291 million |

| CAGR | 4.3% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| by Type |

|

| by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Haas Automation, HURCO, MAKINO, OKUMA, SMTCL Americas, Yamazaki Mazak, CMS North America, Jyoti CNC Automation, Komatsu NTC, KRUDO Industrial, Mitsubishi Electric, DMG MORI, BFW |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |