What is Global Submerged Arc Wires and Fluxes Market?

The Global Submerged Arc Wires and Fluxes Market is a specialized segment within the welding industry that focuses on the production and distribution of materials used in submerged arc welding (SAW). This market encompasses a variety of wires and fluxes that are essential for the SAW process, which is known for its efficiency and high-quality welds. Submerged arc welding is a process where the arc is struck beneath a covering layer of flux, which protects the weld from atmospheric contamination and stabilizes the arc. The market for these materials is driven by their extensive use in industries that require robust and durable welds, such as shipbuilding, construction, and pipeline manufacturing. The demand for submerged arc wires and fluxes is influenced by factors such as advancements in welding technology, the growth of end-use industries, and the need for cost-effective and high-strength welding solutions. As industries continue to expand and modernize, the Global Submerged Arc Wires and Fluxes Market is expected to grow, offering opportunities for manufacturers and suppliers to innovate and meet the evolving needs of their customers.

Submerged Arc Wire, Submerged Arc Flux in the Global Submerged Arc Wires and Fluxes Market:

Submerged Arc Wire and Submerged Arc Flux are integral components of the submerged arc welding process, each playing a crucial role in achieving high-quality welds. Submerged Arc Wire is a consumable electrode that melts under the heat of the welding arc to form the weld joint. It is typically made from materials such as carbon steel, stainless steel, or alloy steel, depending on the specific requirements of the welding application. The wire is fed continuously into the weld pool, providing a consistent supply of filler material that ensures strong and durable welds. On the other hand, Submerged Arc Flux is a granular material that covers the welding arc and the molten weld pool. It serves multiple purposes, including protecting the weld from atmospheric contamination, stabilizing the arc, and influencing the chemical composition of the weld metal. Flux can be made from a variety of compounds, including silica, manganese, and calcium, and can be tailored to meet specific welding needs. The combination of submerged arc wire and flux allows for deep penetration and high deposition rates, making it ideal for welding thick materials and large structures. In the Global Submerged Arc Wires and Fluxes Market, these products are continually being developed and refined to enhance their performance and meet the demands of various industries. Manufacturers are focusing on improving the efficiency and effectiveness of these materials, ensuring they can withstand the rigorous conditions of industrial applications. As a result, the market is characterized by a wide range of products, each designed to meet specific welding challenges and requirements.

Automobile, Shipbuilding, Marine Engineering, Pressure Vessel, Construction Bridge, Engineering Machinery, Pipeline Storage Tank in the Global Submerged Arc Wires and Fluxes Market:

The usage of Global Submerged Arc Wires and Fluxes Market products spans several key industries, each benefiting from the unique advantages of submerged arc welding. In the automobile industry, these materials are used to create strong and reliable welds in the manufacturing of vehicle frames and components. The high deposition rates and deep penetration capabilities of submerged arc welding make it ideal for producing the robust structures needed to ensure vehicle safety and performance. In shipbuilding and marine engineering, submerged arc wires and fluxes are essential for constructing the hulls and superstructures of ships. The process provides the strength and durability required to withstand harsh marine environments, ensuring the longevity and reliability of vessels. Similarly, in the construction of pressure vessels, submerged arc welding is used to create the thick, high-strength welds necessary to contain high-pressure fluids and gases safely. The construction bridge industry also relies on submerged arc welding for its ability to produce long, continuous welds that are crucial for the structural integrity of bridges. Engineering machinery, which includes heavy equipment and industrial machines, benefits from the precision and strength of submerged arc welds, ensuring the reliability and efficiency of these critical tools. In the pipeline industry, submerged arc wires and fluxes are used to join sections of pipe, creating leak-proof and durable connections that are essential for transporting oil, gas, and other fluids. Finally, in the construction of storage tanks, submerged arc welding provides the robust welds needed to ensure the safe and secure containment of liquids and gases. Across these industries, the Global Submerged Arc Wires and Fluxes Market plays a vital role in enabling the production of high-quality, reliable, and durable welded structures.

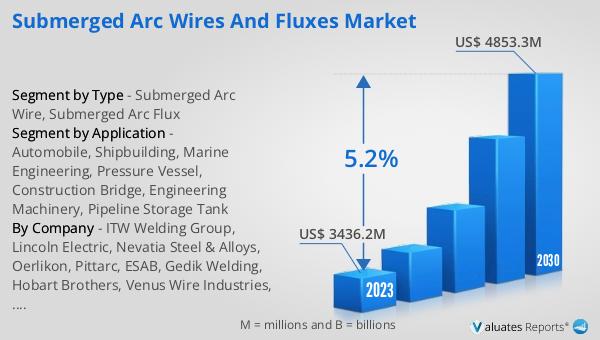

Global Submerged Arc Wires and Fluxes Market Outlook:

The global market for Submerged Arc Wires and Fluxes was valued at $3,748 million in 2024 and is anticipated to expand to a revised size of $5,318 million by 2031, reflecting a compound annual growth rate (CAGR) of 5.2% during the forecast period. This growth trajectory underscores the increasing demand for submerged arc welding materials across various industries. The market's expansion is driven by the need for efficient and high-quality welding solutions that can meet the rigorous demands of modern industrial applications. As industries such as shipbuilding, construction, and pipeline manufacturing continue to grow and evolve, the demand for submerged arc wires and fluxes is expected to rise. This growth presents opportunities for manufacturers and suppliers to innovate and develop new products that meet the changing needs of their customers. The market's projected growth also highlights the importance of submerged arc welding in enabling the production of strong, durable, and reliable welded structures. As the market continues to expand, it will play a crucial role in supporting the growth and development of key industries around the world.

| Report Metric | Details |

| Report Name | Submerged Arc Wires and Fluxes Market |

| Accounted market size in year | US$ 3748 million |

| Forecasted market size in 2031 | US$ 5318 million |

| CAGR | 5.2% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| by Type |

|

| by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | ITW Welding Group, Lincoln Electric, Nevatia Steel & Alloys, Oerlikon, Pittarc, ESAB, Gedik Welding, Hobart Brothers, Venus Wire Industries, Vorarc Welding, WB Alloy Welding, Certilas, Bavaria Schweisstechnik, Atlantic China Welding Consumables, Shandong Solid Solder, Shandong Juli Welding, Beijing Jinwei Weld Materials, Baoding Lanyu Welding Material, Hit Welding Industry, Tianjin Golden Bridge Welding Materials Internationl, Tianjin Bridge Welding Materials Group |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |