What is Global Pharmaceutical High Borosilicate Glass Market?

The Global Pharmaceutical High Borosilicate Glass Market is a specialized segment within the broader pharmaceutical packaging industry, focusing on the use of high borosilicate glass. This type of glass is renowned for its superior chemical durability, thermal resistance, and mechanical strength, making it an ideal choice for pharmaceutical applications. High borosilicate glass is primarily used in the production of containers and packaging solutions that store and protect sensitive pharmaceutical products. Its unique properties ensure that the contents remain uncontaminated and stable over time, which is crucial for maintaining the efficacy and safety of medications. The market for this glass is driven by the increasing demand for safe and reliable packaging solutions in the pharmaceutical industry, as well as the growing emphasis on sustainability and recyclability. As pharmaceutical companies continue to innovate and develop new drugs, the need for high-quality packaging materials like high borosilicate glass is expected to rise, further propelling the market's growth.

Ordinary High Borosilicate Glass, Float High Borosilicate Glass in the Global Pharmaceutical High Borosilicate Glass Market:

Ordinary High Borosilicate Glass and Float High Borosilicate Glass are two significant types of glass used in the Global Pharmaceutical High Borosilicate Glass Market. Ordinary High Borosilicate Glass is known for its excellent thermal and chemical stability, which makes it suitable for a wide range of pharmaceutical applications. This type of glass is often used in the production of laboratory equipment, such as beakers and test tubes, due to its ability to withstand high temperatures and resist chemical reactions. Its durability ensures that it can be used repeatedly without degrading, which is essential in laboratory settings where precision and reliability are paramount. On the other hand, Float High Borosilicate Glass is produced using a float process, which involves floating molten glass on a bed of molten metal, typically tin. This process results in a glass that is exceptionally flat and smooth, with uniform thickness. Float High Borosilicate Glass is often used in the production of flat glass products, such as windows and screens, but its application in the pharmaceutical industry is primarily focused on packaging solutions. The smooth surface of float glass makes it ideal for creating airtight seals, which are crucial for maintaining the sterility and integrity of pharmaceutical products. Both types of glass offer unique advantages that cater to different needs within the pharmaceutical industry. While Ordinary High Borosilicate Glass is favored for its robustness and versatility, Float High Borosilicate Glass is preferred for its precision and ability to create secure packaging solutions. The choice between these two types of glass often depends on the specific requirements of the pharmaceutical product being packaged. For instance, medications that require high-temperature sterilization processes may benefit from the use of Ordinary High Borosilicate Glass, while products that need airtight packaging might be better suited to Float High Borosilicate Glass. As the pharmaceutical industry continues to evolve, the demand for both types of high borosilicate glass is expected to grow, driven by the need for safe, reliable, and sustainable packaging solutions.

Glass Tube, Glass Vial, Others in the Global Pharmaceutical High Borosilicate Glass Market:

The Global Pharmaceutical High Borosilicate Glass Market finds its applications in various areas, including Glass Tubes, Glass Vials, and other specialized uses. Glass Tubes made from high borosilicate glass are widely used in the pharmaceutical industry for their excellent thermal and chemical resistance. These tubes are often employed in laboratory settings for conducting experiments and storing chemical samples. Their ability to withstand high temperatures and resist chemical reactions makes them ideal for use in environments where precision and reliability are crucial. Additionally, glass tubes are used in the production of ampoules, which are small sealed vials used to contain and preserve liquid samples. The use of high borosilicate glass ensures that the contents of the ampoules remain uncontaminated and stable over time. Glass Vials, another critical application of high borosilicate glass, are used extensively for packaging and storing pharmaceutical products. These vials are designed to protect the contents from external factors such as light, moisture, and air, which can compromise the efficacy and safety of the medication. High borosilicate glass vials are particularly favored for their ability to maintain the sterility and integrity of the contents, making them an essential component in the packaging of injectable drugs and vaccines. The use of high borosilicate glass in vials also ensures that the packaging is durable and resistant to breakage, which is crucial for maintaining the safety of the product during transportation and storage. Beyond Glass Tubes and Glass Vials, high borosilicate glass is also used in other specialized applications within the pharmaceutical industry. For instance, it is used in the production of glass syringes, which are preferred for their precision and ability to deliver accurate dosages. The use of high borosilicate glass in syringes ensures that the medication remains uncontaminated and that the syringe can withstand repeated use without degrading. Additionally, high borosilicate glass is used in the production of glass pipettes, which are essential tools in laboratory settings for measuring and transferring small volumes of liquid. The unique properties of high borosilicate glass make it an ideal material for these applications, ensuring that the tools remain reliable and accurate over time. As the pharmaceutical industry continues to grow and innovate, the demand for high borosilicate glass in these applications is expected to increase, driven by the need for safe, reliable, and sustainable packaging and laboratory solutions.

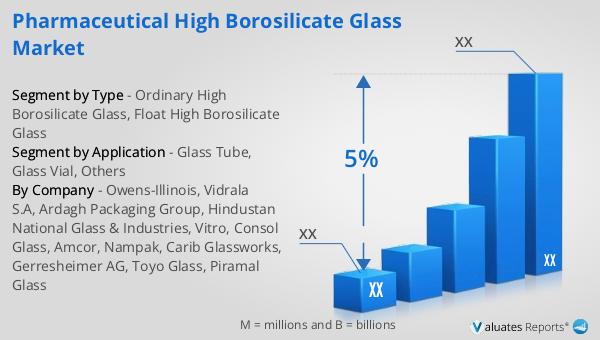

Global Pharmaceutical High Borosilicate Glass Market Outlook:

In 2022, the global pharmaceutical market reached a valuation of 1,475 billion USD, marking a significant milestone in the industry. This market is projected to grow at a compound annual growth rate (CAGR) of 5% over the next six years, indicating a steady and robust expansion. In contrast, the chemical drug market has shown a different growth trajectory. From 2018 to 2022, the chemical drug market experienced an increase from 1,005 billion USD to 1,094 billion USD. This growth reflects the ongoing demand for chemical drugs, albeit at a slightly slower pace compared to the broader pharmaceutical market. The differences in growth rates between the overall pharmaceutical market and the chemical drug segment highlight the dynamic nature of the industry, with various factors influencing each segment's development. The pharmaceutical market's growth is driven by several factors, including advancements in drug development, increasing healthcare needs, and a growing emphasis on personalized medicine. As the industry continues to evolve, the demand for innovative and effective pharmaceutical solutions is expected to rise, further fueling the market's expansion. The chemical drug market, while growing at a slower rate, remains a vital component of the pharmaceutical industry, providing essential medications that address a wide range of health conditions.

| Report Metric | Details |

| Report Name | Pharmaceutical High Borosilicate Glass Market |

| CAGR | 5% |

| Segment by Type |

|

| Segment by Application |

|

| Consumption by Region |

|

| By Company | Owens-Illinois, Vidrala S.A, Ardagh Packaging Group, Hindustan National Glass & Industries, Vitro, Consol Glass, Amcor, Nampak, Carib Glassworks, Gerresheimer AG, Toyo Glass, Piramal Glass |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |