What is Global PET Functional Film Materials Market?

The Global PET Functional Film Materials Market is a dynamic and rapidly evolving sector that plays a crucial role in various industries worldwide. PET, or polyethylene terephthalate, is a type of polyester that is widely used due to its excellent mechanical and chemical properties. Functional films made from PET are utilized in numerous applications, ranging from packaging to electronics, due to their versatility, durability, and cost-effectiveness. These films are engineered to enhance the performance of products by providing features such as barrier protection, electrical insulation, and optical clarity. The market for PET functional film materials is driven by the increasing demand for high-performance materials that can meet the stringent requirements of modern applications. As industries continue to innovate and seek sustainable solutions, PET functional films are becoming an integral part of the global supply chain, offering a balance between performance and environmental responsibility. The market's growth is further fueled by advancements in manufacturing technologies and the development of new film formulations that cater to specific industry needs. As a result, the Global PET Functional Film Materials Market is poised for significant expansion, reflecting the growing importance of these materials in the global economy.

Ultra-thin Film, Thin Film, Thick Film in the Global PET Functional Film Materials Market:

In the realm of Global PET Functional Film Materials, the classification into ultra-thin, thin, and thick films is essential for understanding their diverse applications and functionalities. Ultra-thin films, typically less than 1 micron in thickness, are primarily used in applications where minimal material usage is crucial, such as in microelectronics and advanced display technologies. These films offer exceptional flexibility and transparency, making them ideal for use in touch screens, flexible displays, and other high-tech applications where precision and clarity are paramount. The production of ultra-thin films requires advanced manufacturing techniques to ensure uniformity and performance, often involving sophisticated coating and deposition processes. Thin films, generally ranging from 1 to 10 microns, are widely used across various industries due to their balance of performance and cost-effectiveness. They are commonly employed in packaging, where they provide excellent barrier properties against moisture, gases, and other environmental factors. In the electronics industry, thin PET films are used as dielectric layers in capacitors and as substrates for printed circuit boards, offering electrical insulation and mechanical support. The versatility of thin films extends to the automotive sector, where they are used in window films and protective coatings, enhancing durability and UV resistance. Thick films, typically over 10 microns, are utilized in applications requiring robust mechanical properties and enhanced durability. These films are often used in industrial settings, where they serve as protective layers against abrasion, chemicals, and extreme temperatures. In the construction industry, thick PET films are used in safety and security applications, such as laminated glass and protective barriers. The production of thick films involves extrusion and lamination processes that ensure the films maintain their structural integrity under demanding conditions. Across all thickness categories, the Global PET Functional Film Materials Market is driven by the need for materials that offer a combination of performance, reliability, and sustainability. As industries continue to evolve, the demand for specialized PET films that meet specific application requirements is expected to grow, highlighting the importance of innovation and technological advancement in this dynamic market.

Packaging, Electrical and Electronics, Food & Beverage, Industrial, Others in the Global PET Functional Film Materials Market:

The Global PET Functional Film Materials Market finds extensive usage across a variety of sectors, each leveraging the unique properties of PET films to enhance product performance and sustainability. In the packaging industry, PET films are prized for their excellent barrier properties, which protect products from moisture, oxygen, and other environmental factors. This makes them ideal for food and beverage packaging, where maintaining freshness and extending shelf life are critical. PET films are also used in flexible packaging solutions, offering lightweight and durable alternatives to traditional materials. In the electrical and electronics sector, PET films serve as essential components in a wide range of applications. They are used as dielectric layers in capacitors, substrates for flexible printed circuit boards, and insulation materials in cables and wires. The films' electrical insulation properties, combined with their mechanical strength and thermal stability, make them indispensable in the production of electronic devices and components. In the food and beverage industry, PET films are used not only for packaging but also in labeling and tamper-evident seals, ensuring product safety and compliance with regulatory standards. The films' clarity and printability allow for high-quality graphics and branding, enhancing product appeal on store shelves. In industrial applications, PET films are used as protective coatings and laminates, providing resistance to abrasion, chemicals, and extreme temperatures. They are employed in the production of safety and security films, offering enhanced protection in construction and automotive applications. Additionally, PET films are used in the production of solar panels and other renewable energy technologies, contributing to the development of sustainable energy solutions. Beyond these sectors, PET films are also used in a variety of other applications, including medical devices, textiles, and consumer goods, where their versatility and performance characteristics are highly valued. As industries continue to seek innovative solutions to meet evolving consumer demands and regulatory requirements, the Global PET Functional Film Materials Market is poised to play a pivotal role in driving advancements across multiple sectors.

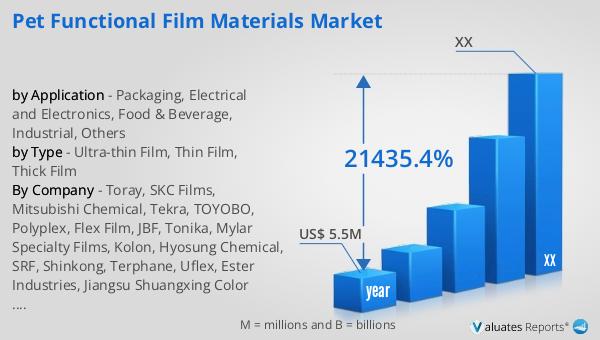

Global PET Functional Film Materials Market Outlook:

The outlook for the Global PET Functional Film Materials Market is characterized by remarkable growth and expansion. In 2024, the market was valued at approximately $5.5 million, reflecting its established presence and importance across various industries. However, the market is projected to experience unprecedented growth, reaching an astounding size of approximately $1.0638975611509715e17 million by 2031. This exponential increase is indicative of a compound annual growth rate (CAGR) of 21435.4% during the forecast period. Such a staggering growth rate underscores the increasing demand for PET functional films, driven by their versatility, performance, and sustainability. The market's expansion is fueled by advancements in manufacturing technologies, the development of new film formulations, and the growing emphasis on sustainable and environmentally friendly materials. As industries continue to innovate and seek high-performance solutions, PET functional films are becoming an integral part of the global supply chain, offering a balance between performance and environmental responsibility. The projected growth of the Global PET Functional Film Materials Market highlights the critical role these materials play in driving advancements across multiple sectors, from packaging and electronics to industrial applications and beyond. As the market continues to evolve, it is poised to make significant contributions to the global economy, reflecting the growing importance of PET functional films in meeting the demands of modern applications.

| Report Metric | Details |

| Report Name | PET Functional Film Materials Market |

| Accounted market size in year | US$ 5.5 million |

| CAGR | 21435.4% |

| Base Year | year |

| by Type |

|

| by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Toray, SKC Films, Mitsubishi Chemical, Tekra, TOYOBO, Polyplex, Flex Film, JBF, Tonika, Mylar Specialty Films, Kolon, Hyosung Chemical, SRF, Shinkong, Terphane, Uflex, Ester Industries, Jiangsu Shuangxing Color Plastic New Materials, Sichuan EM Technology, JiangSu YuXing Film Technology, Jiangsu Sidike New Materials Science & Technology, Zhejiang Jiemei Electronic and Technology, Fujian Billion, Hengli Group, Sanfangxiang Group, Solartron Technology, Zhejiang Great Southeast |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |