What is Global Paper Surface Strength Enhancer Market?

The Global Paper Surface Strength Enhancer Market is a specialized segment within the broader paper industry, focusing on products that improve the surface strength of paper materials. These enhancers are crucial for ensuring that paper products can withstand various stresses during processing, printing, and usage. The market encompasses a range of chemical additives and treatments designed to enhance the durability and performance of paper surfaces. These enhancers are used in various applications, including printing, packaging, and specialty papers, where surface strength is a critical factor. The demand for paper surface strength enhancers is driven by the need for high-quality paper products that can meet the rigorous demands of modern printing technologies and consumer expectations. As the paper industry continues to evolve, with increasing emphasis on sustainability and performance, the role of surface strength enhancers becomes even more significant. These products not only improve the functional properties of paper but also contribute to the overall efficiency and cost-effectiveness of paper production processes. The market is characterized by continuous innovation, with manufacturers developing new formulations and technologies to meet the changing needs of the paper industry.

Wet Strength Agent, Dry Strength Agent in the Global Paper Surface Strength Enhancer Market:

In the realm of the Global Paper Surface Strength Enhancer Market, Wet Strength Agents and Dry Strength Agents play pivotal roles. Wet Strength Agents are chemicals added to paper to enhance its strength when wet. This is particularly important for products like paper towels, tissues, and packaging materials that may encounter moisture. These agents work by forming chemical bonds that are resistant to water, thereby maintaining the integrity of the paper even when it is wet. The use of wet strength agents is crucial in applications where paper products are expected to retain their strength and functionality in damp conditions. On the other hand, Dry Strength Agents are used to improve the strength of paper when it is dry. These agents enhance the internal bonding of paper fibers, resulting in improved tensile strength, burst strength, and folding endurance. Dry strength agents are essential in the production of high-quality printing papers, packaging materials, and specialty papers where strength and durability are key requirements. Both wet and dry strength agents are integral to the paper manufacturing process, contributing to the production of paper products that meet the diverse needs of consumers and industries. The choice between wet and dry strength agents depends on the specific requirements of the paper product and its intended use. Manufacturers in the Global Paper Surface Strength Enhancer Market are continually innovating to develop new and improved formulations of these agents, ensuring that they meet the evolving demands of the paper industry. The development of environmentally friendly and sustainable strength agents is also a growing trend in the market, reflecting the increasing emphasis on sustainability in the paper industry. As the market continues to grow, the role of wet and dry strength agents in enhancing the performance and quality of paper products remains critical.

Paper, Paper Board, Others in the Global Paper Surface Strength Enhancer Market:

The Global Paper Surface Strength Enhancer Market finds its applications in various areas, including paper, paperboard, and other related products. In the paper industry, surface strength enhancers are used to improve the printability and durability of paper products. These enhancers ensure that the paper can withstand the mechanical stresses of printing processes and maintain high-quality print results. This is particularly important for high-end printing applications, such as magazines, brochures, and packaging materials, where the appearance and performance of the paper are crucial. In the paperboard sector, surface strength enhancers play a vital role in enhancing the structural integrity and performance of paperboard products. Paperboard is widely used in packaging applications, where strength and durability are essential. Surface strength enhancers help improve the resistance of paperboard to tearing, bursting, and other mechanical stresses, ensuring that packaging materials can protect their contents effectively. In addition to paper and paperboard, surface strength enhancers are also used in other applications, such as specialty papers and non-paper products. Specialty papers, such as those used in currency, security documents, and labels, require high levels of strength and durability, which can be achieved through the use of surface strength enhancers. Non-paper products, such as laminates and composites, also benefit from the use of these enhancers, which improve their performance and longevity. The versatility and effectiveness of surface strength enhancers make them an essential component in the production of a wide range of paper and paper-related products. As the demand for high-quality and sustainable paper products continues to grow, the role of surface strength enhancers in the paper industry is expected to become increasingly important.

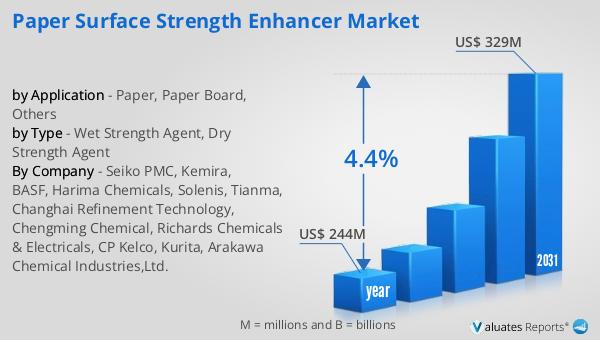

Global Paper Surface Strength Enhancer Market Outlook:

In 2024, the global market for Paper Surface Strength Enhancers was valued at approximately $244 million. This market is anticipated to expand significantly, reaching an estimated value of $329 million by 2031. This growth trajectory represents a compound annual growth rate (CAGR) of 4.4% over the forecast period. The increasing demand for high-quality paper products, driven by advancements in printing technologies and consumer expectations, is a key factor contributing to this growth. As industries continue to seek innovative solutions to enhance the performance and sustainability of paper products, the demand for surface strength enhancers is expected to rise. These enhancers play a crucial role in improving the durability and functionality of paper products, making them indispensable in various applications. The market's growth is also supported by ongoing research and development efforts aimed at creating new and improved formulations of surface strength enhancers. As the paper industry evolves, with a growing emphasis on sustainability and performance, the importance of surface strength enhancers is likely to increase. This market outlook highlights the significant opportunities for growth and innovation in the Global Paper Surface Strength Enhancer Market, driven by the need for high-quality and sustainable paper products.

| Report Metric | Details |

| Report Name | Paper Surface Strength Enhancer Market |

| Accounted market size in year | US$ 244 million |

| Forecasted market size in 2031 | US$ 329 million |

| CAGR | 4.4% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| by Type |

|

| by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Seiko PMC, Kemira, BASF, Harima Chemicals, Solenis, Tianma, Changhai Refinement Technology, Chengming Chemical, Richards Chemicals & Electricals, CP Kelco, Kurita, Arakawa Chemical Industries,Ltd. |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |