What is Global Paper Surface Enhancer Market?

The Global Paper Surface Enhancer Market is a specialized segment within the broader paper industry, focusing on products that improve the surface properties of paper. These enhancers are crucial for enhancing the quality and functionality of paper products, making them more suitable for various applications. Surface enhancers are used to improve the printability, gloss, and smoothness of paper, which are essential for high-quality printing and packaging. The market for these enhancers is driven by the increasing demand for high-quality paper products in industries such as packaging, printing, and publishing. As consumer preferences shift towards more aesthetically pleasing and functional paper products, the demand for surface enhancers is expected to grow. Additionally, advancements in technology and the development of new and improved enhancer formulations are contributing to the market's expansion. The global market for paper surface enhancers is characterized by a diverse range of products, each designed to meet specific requirements of different paper types and applications. This market is poised for growth as industries continue to seek innovative solutions to enhance the quality and performance of their paper products.

Wet Strength Agent, Dry Strength Agent in the Global Paper Surface Enhancer Market:

Wet Strength Agents and Dry Strength Agents are two critical components in the Global Paper Surface Enhancer Market, each serving distinct purposes in enhancing paper quality. Wet Strength Agents are chemicals added to paper to improve its strength when wet. This is particularly important for products like paper towels, tissues, and packaging materials that may encounter moisture. The primary function of wet strength agents is to maintain the integrity and durability of paper when exposed to water or other liquids. These agents work by forming chemical bonds with the cellulose fibers in the paper, creating a network that holds the fibers together even when wet. This ensures that the paper does not disintegrate or lose its structural integrity, making it suitable for applications where moisture resistance is crucial. On the other hand, Dry Strength Agents are used to enhance the strength of paper when it is dry. These agents are essential for improving the tensile, burst, and tear strength of paper, making it more durable and resistant to damage during handling and processing. Dry strength agents work by increasing the bonding between the fibers in the paper, resulting in a stronger and more resilient product. This is particularly important for applications such as printing and packaging, where the paper needs to withstand mechanical stress and pressure. The use of dry strength agents also contributes to the overall quality and performance of paper products, ensuring that they meet the required standards for various applications. Both wet and dry strength agents play a vital role in the paper industry, providing solutions to enhance the quality and functionality of paper products. As the demand for high-quality paper continues to grow, the importance of these agents in the Global Paper Surface Enhancer Market is expected to increase. Manufacturers are continually developing new and improved formulations to meet the evolving needs of the industry, ensuring that paper products remain competitive in the market. The integration of these agents into the paper manufacturing process not only improves the physical properties of paper but also contributes to its sustainability by reducing the need for additional raw materials. This is particularly important in today's environmentally conscious market, where sustainability is a key consideration for consumers and manufacturers alike. Overall, Wet Strength Agents and Dry Strength Agents are indispensable components of the Global Paper Surface Enhancer Market, providing essential solutions to enhance the quality and performance of paper products across various industries.

Paper, Paper Board, Others in the Global Paper Surface Enhancer Market:

The Global Paper Surface Enhancer Market finds its applications in various areas, including paper, paperboard, and other related products. In the paper industry, surface enhancers are used to improve the printability, gloss, and smoothness of paper, making it suitable for high-quality printing applications. This is particularly important for products such as magazines, brochures, and catalogs, where the visual appeal and clarity of printed images are crucial. Surface enhancers help achieve a uniform and smooth surface, allowing for better ink adhesion and color reproduction. This results in sharper and more vibrant prints, enhancing the overall quality of the final product. In the paperboard industry, surface enhancers are used to improve the strength and durability of packaging materials. Paperboard is commonly used for packaging applications, including boxes, cartons, and containers. Surface enhancers help improve the structural integrity of paperboard, making it more resistant to damage during handling and transportation. This is particularly important for packaging applications, where the materials need to withstand mechanical stress and pressure. Additionally, surface enhancers can improve the moisture resistance of paperboard, ensuring that the packaging remains intact even in humid or wet conditions. This is crucial for protecting the contents of the package and maintaining the quality of the product. Beyond paper and paperboard, surface enhancers are also used in other related products, such as specialty papers and non-woven materials. Specialty papers, such as those used for labels, envelopes, and stationery, require specific surface properties to meet the demands of their applications. Surface enhancers help achieve the desired characteristics, such as smoothness, gloss, and printability, ensuring that the final product meets the required standards. Non-woven materials, which are used in applications such as hygiene products and medical supplies, also benefit from the use of surface enhancers. These materials require specific properties, such as softness, absorbency, and strength, to meet the demands of their applications. Surface enhancers help achieve these properties, ensuring that the final product is suitable for its intended use. Overall, the Global Paper Surface Enhancer Market plays a crucial role in enhancing the quality and performance of paper, paperboard, and other related products. As the demand for high-quality and functional paper products continues to grow, the importance of surface enhancers in the industry is expected to increase. Manufacturers are continually developing new and improved formulations to meet the evolving needs of the market, ensuring that paper products remain competitive and meet the demands of consumers.

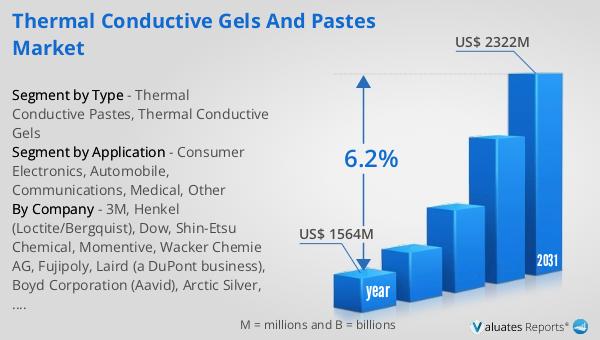

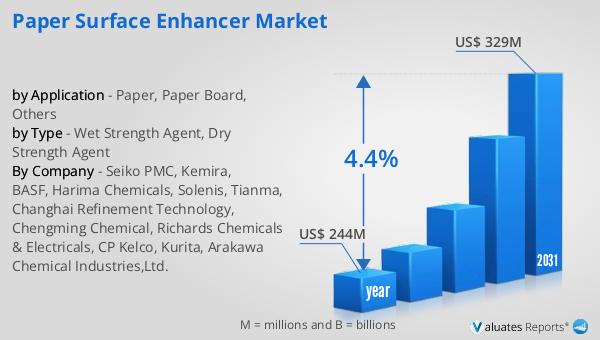

Global Paper Surface Enhancer Market Outlook:

In 2024, the global market for Paper Surface Enhancers was valued at approximately $244 million. This market is anticipated to grow steadily, reaching an estimated value of $329 million by 2031. This growth trajectory represents a compound annual growth rate (CAGR) of 4.4% over the forecast period. The increasing demand for high-quality paper products across various industries, such as packaging, printing, and publishing, is a significant driver of this market growth. As consumer preferences shift towards more aesthetically pleasing and functional paper products, the need for surface enhancers is expected to rise. These enhancers play a crucial role in improving the printability, gloss, and smoothness of paper, making them essential for producing high-quality paper products. Additionally, advancements in technology and the development of new and improved enhancer formulations are contributing to the market's expansion. The global market for paper surface enhancers is characterized by a diverse range of products, each designed to meet specific requirements of different paper types and applications. As industries continue to seek innovative solutions to enhance the quality and performance of their paper products, the market for paper surface enhancers is poised for growth. This growth is further supported by the increasing focus on sustainability and environmentally friendly solutions, as surface enhancers can help reduce the need for additional raw materials in paper production. Overall, the global market for paper surface enhancers is expected to experience steady growth in the coming years, driven by the increasing demand for high-quality paper products and the development of new and improved enhancer formulations.

| Report Metric | Details |

| Report Name | Paper Surface Enhancer Market |

| Accounted market size in year | US$ 244 million |

| Forecasted market size in 2031 | US$ 329 million |

| CAGR | 4.4% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| by Type |

|

| by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Seiko PMC, Kemira, BASF, Harima Chemicals, Solenis, Tianma, Changhai Refinement Technology, Chengming Chemical, Richards Chemicals & Electricals, CP Kelco, Kurita, Arakawa Chemical Industries,Ltd. |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |