What is Global No Clean Flux Pen Market?

The Global No Clean Flux Pen Market is a specialized segment within the electronics industry, focusing on the production and distribution of flux pens that do not require post-soldering cleaning. These pens are essential tools in soldering processes, particularly in electronics manufacturing, where they help improve the soldering quality by removing oxides and other impurities from metal surfaces. The "no clean" aspect refers to the flux's ability to leave minimal residues that do not need to be cleaned off after soldering, thus saving time and reducing costs associated with cleaning processes. This market is driven by the increasing demand for efficient and cost-effective soldering solutions in various electronic applications, including consumer electronics, automotive electronics, and telecommunications. The growth of the electronics industry, coupled with advancements in soldering technologies, has led to a rise in the adoption of no clean flux pens. Manufacturers in this market are continually innovating to improve the performance and environmental friendliness of their products, catering to the evolving needs of the electronics sector. As a result, the Global No Clean Flux Pen Market is poised for steady growth, driven by technological advancements and the increasing complexity of electronic devices.

10ml, 12ml in the Global No Clean Flux Pen Market:

In the Global No Clean Flux Pen Market, the 10ml and 12ml flux pens are popular choices among manufacturers and technicians due to their convenient sizes and ease of use. These pens are designed to provide precise application of flux, which is crucial in achieving high-quality solder joints. The 10ml flux pen is often favored for its compact size, making it ideal for small-scale operations or for use in confined spaces where larger applicators might be cumbersome. It is particularly useful in applications where precision is paramount, such as in the assembly of small electronic components or in repair work where targeted application is necessary. The 12ml flux pen, on the other hand, offers a slightly larger capacity, which can be advantageous in more extensive manufacturing processes or in situations where frequent refilling of the pen would be impractical. This size strikes a balance between capacity and maneuverability, making it a versatile tool in various soldering applications. Both sizes are equipped with a felt tip that allows for controlled dispensing of the flux, ensuring that the right amount is applied to the desired area without wastage. The choice between a 10ml and a 12ml flux pen often depends on the specific requirements of the task at hand, including the scale of the operation, the complexity of the soldering work, and the preferences of the technician. In terms of market dynamics, the demand for these flux pens is influenced by the overall growth of the electronics industry, as well as by trends in miniaturization and the increasing complexity of electronic devices. As electronic components become smaller and more intricate, the need for precise and efficient soldering solutions becomes more critical, driving the demand for high-quality flux pens. Additionally, environmental considerations are playing an increasingly important role in the market, with manufacturers focusing on developing flux formulations that are not only effective but also environmentally friendly. This includes reducing the use of harmful chemicals and ensuring that any residues left behind are non-corrosive and safe for both the components and the environment. The Global No Clean Flux Pen Market is also characterized by a high level of competition, with numerous players vying for market share. This competition drives innovation, leading to the development of new and improved products that meet the evolving needs of the electronics industry. Companies are investing in research and development to enhance the performance of their flux pens, focusing on factors such as ease of use, reliability, and environmental impact. As a result, the market is witnessing the introduction of flux pens with advanced features, such as improved flow control, longer shelf life, and compatibility with a wider range of soldering materials. In conclusion, the 10ml and 12ml flux pens are integral components of the Global No Clean Flux Pen Market, offering solutions that cater to the diverse needs of the electronics industry. Their popularity is driven by their convenience, precision, and adaptability to various soldering applications, making them indispensable tools for manufacturers and technicians alike. As the market continues to evolve, these flux pens are expected to play a crucial role in supporting the growth and advancement of the electronics sector.

Leaded Applications, Lead Free Applications in the Global No Clean Flux Pen Market:

The Global No Clean Flux Pen Market finds significant usage in both leaded and lead-free applications, catering to the diverse needs of the electronics industry. In leaded applications, no clean flux pens are used to facilitate the soldering process by removing oxides and impurities from the metal surfaces, ensuring strong and reliable solder joints. The flux in these pens is formulated to work effectively with leaded solder, which has been traditionally used in many electronic assemblies due to its lower melting point and ease of use. The no clean aspect of the flux is particularly beneficial in leaded applications, as it eliminates the need for post-soldering cleaning, saving time and reducing costs. This is especially important in high-volume manufacturing environments where efficiency and cost-effectiveness are critical. In lead-free applications, no clean flux pens play a crucial role in addressing the challenges associated with lead-free soldering. With the increasing emphasis on environmental sustainability and the regulatory push towards eliminating lead from electronic products, the demand for lead-free soldering solutions has been on the rise. Lead-free solders typically have higher melting points and different wetting characteristics compared to leaded solders, making the soldering process more challenging. No clean flux pens formulated for lead-free applications are designed to enhance the solderability of lead-free solders, ensuring strong and reliable joints while minimizing defects such as voids and poor wetting. The use of no clean flux pens in lead-free applications also aligns with the industry's move towards more environmentally friendly manufacturing practices. By eliminating the need for cleaning, these pens help reduce the use of cleaning solvents and the generation of waste, contributing to a more sustainable production process. Additionally, the residues left behind by no clean flux pens are typically non-corrosive and safe for both the components and the environment, further supporting the industry's sustainability goals. The versatility of no clean flux pens in both leaded and lead-free applications makes them indispensable tools in the electronics industry. They provide manufacturers with the flexibility to adapt to different soldering requirements while maintaining high standards of quality and efficiency. As the industry continues to evolve, the demand for no clean flux pens is expected to grow, driven by the increasing complexity of electronic devices and the ongoing shift towards more sustainable manufacturing practices. In summary, the Global No Clean Flux Pen Market plays a vital role in supporting both leaded and lead-free soldering applications, offering solutions that enhance solderability, improve efficiency, and align with the industry's sustainability goals.

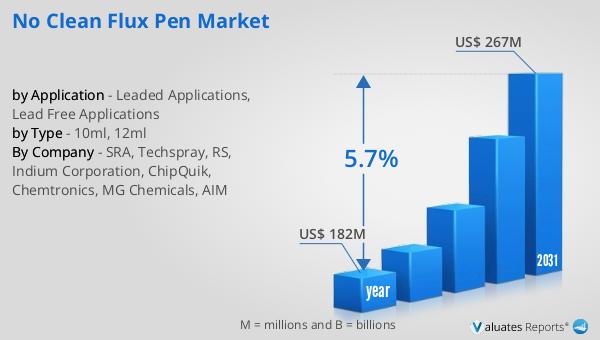

Global No Clean Flux Pen Market Outlook:

The worldwide market for No Clean Flux Pens was estimated to be worth $182 million in 2024. By 2031, it is anticipated to expand to a new size of $267 million, reflecting a compound annual growth rate (CAGR) of 5.7% over the forecast period. This growth trajectory highlights the increasing demand for no clean flux pens, driven by the expanding electronics industry and the need for efficient soldering solutions. The market's steady growth is indicative of the rising adoption of no clean flux pens across various applications, including consumer electronics, automotive electronics, and telecommunications. As electronic devices become more complex and miniaturized, the demand for precise and reliable soldering tools like no clean flux pens is expected to rise. Additionally, the market's growth is supported by the industry's shift towards more environmentally friendly manufacturing practices, with no clean flux pens offering a solution that minimizes the need for cleaning and reduces waste. The competitive landscape of the market is characterized by continuous innovation, with manufacturers investing in research and development to enhance the performance and environmental friendliness of their products. This includes the development of new flux formulations that are effective, safe, and compliant with environmental regulations. As a result, the Global No Clean Flux Pen Market is poised for sustained growth, driven by technological advancements, increasing complexity of electronic devices, and the industry's commitment to sustainability.

| Report Metric | Details |

| Report Name | No Clean Flux Pen Market |

| Accounted market size in year | US$ 182 million |

| Forecasted market size in 2031 | US$ 267 million |

| CAGR | 5.7% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| by Type |

|

| by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | SRA, Techspray, RS, Indium Corporation, ChipQuik, Chemtronics, MG Chemicals, AIM |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |