What is Global Mining Truck Tire Market?

The Global Mining Truck Tire Market is a specialized segment within the broader tire industry, focusing on the production and distribution of tires specifically designed for mining trucks. These tires are engineered to withstand the harsh conditions and heavy loads typical in mining operations. Mining truck tires are crucial for the efficient and safe transportation of materials within mining sites, often characterized by rough terrains and extreme weather conditions. The market encompasses various types of tires, including pneumatic, solid, and polyurethane, each offering distinct advantages depending on the specific requirements of the mining operations. The demand for mining truck tires is driven by the growth in mining activities worldwide, as well as advancements in tire technology that enhance durability and performance. As mining companies strive to improve operational efficiency and reduce downtime, the importance of high-quality, reliable tires becomes increasingly evident. The market is also influenced by factors such as regulatory standards, environmental considerations, and the need for cost-effective solutions. Overall, the Global Mining Truck Tire Market plays a vital role in supporting the mining industry by providing essential components that ensure the smooth and efficient functioning of mining operations.

Pneumatic, Solid, Polyurethane in the Global Mining Truck Tire Market:

In the Global Mining Truck Tire Market, three primary types of tires are prevalent: pneumatic, solid, and polyurethane. Pneumatic tires are the most common type used in mining trucks due to their ability to absorb shocks and provide a smoother ride over rough terrains. These tires are filled with air, which allows them to flex and adapt to uneven surfaces, reducing the impact on the vehicle and its cargo. Pneumatic tires are favored for their versatility and cost-effectiveness, making them suitable for a wide range of mining applications. However, they are susceptible to punctures and require regular maintenance to ensure optimal performance. Solid tires, on the other hand, are made entirely of rubber or other resilient materials, offering superior durability and resistance to punctures. These tires are ideal for environments where sharp rocks and debris are common, as they eliminate the risk of flats and reduce downtime associated with tire repairs. Solid tires are often used in underground mining operations where the risk of tire damage is high. Despite their durability, solid tires can be less comfortable for operators due to their rigidity and lack of shock absorption. Polyurethane tires represent a newer innovation in the mining truck tire market, combining the benefits of both pneumatic and solid tires. These tires are made from a durable polyurethane compound that offers excellent resistance to wear and tear, while also providing a degree of flexibility similar to pneumatic tires. Polyurethane tires are particularly advantageous in environments where both durability and comfort are essential, as they can withstand harsh conditions without compromising on ride quality. Additionally, polyurethane tires are often lighter than their rubber counterparts, contributing to improved fuel efficiency and reduced emissions. As the mining industry continues to evolve, the demand for advanced tire solutions that enhance performance, safety, and sustainability is expected to grow, driving further innovation in the Global Mining Truck Tire Market.

OEM, Aftermarket in the Global Mining Truck Tire Market:

The usage of Global Mining Truck Tire Market products can be broadly categorized into two main areas: Original Equipment Manufacturer (OEM) and Aftermarket. OEM refers to the tires that are installed on mining trucks during the manufacturing process. These tires are specifically chosen by the truck manufacturers to meet the performance and safety standards required for new vehicles. OEM tires are designed to provide optimal performance from the outset, ensuring that the mining trucks can operate efficiently and safely in various conditions. The selection of OEM tires is often based on extensive testing and collaboration between tire manufacturers and truck producers to ensure compatibility and reliability. On the other hand, the aftermarket segment involves the replacement of tires after the original ones have worn out or been damaged. Aftermarket tires are crucial for maintaining the operational efficiency of mining trucks, as they ensure that the vehicles remain in good working condition throughout their lifespan. The aftermarket offers a wide range of tire options, allowing mining companies to choose products that best suit their specific needs and budget constraints. This segment is characterized by a high degree of competition, with numerous manufacturers offering various tire models and technologies to cater to different mining environments. The aftermarket also provides opportunities for innovation, as tire manufacturers continually develop new products that offer improved durability, performance, and environmental benefits. Both OEM and aftermarket segments play a vital role in the Global Mining Truck Tire Market, supporting the mining industry by ensuring that trucks are equipped with reliable and efficient tires that meet the demands of modern mining operations.

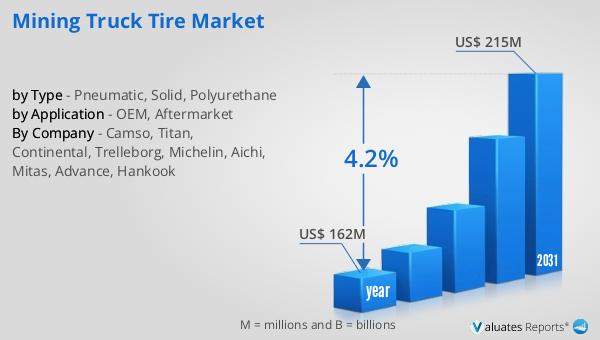

Global Mining Truck Tire Market Outlook:

In 2024, the global market for Mining Truck Tires was valued at approximately $162 million. This market is anticipated to expand, reaching an estimated size of $215 million by 2031. This growth represents a compound annual growth rate (CAGR) of 4.2% over the forecast period. The steady increase in market size reflects the rising demand for mining truck tires, driven by the expansion of mining activities worldwide and the continuous advancements in tire technology. As mining operations become more complex and demanding, the need for high-quality, durable tires that can withstand harsh conditions and heavy loads becomes increasingly critical. The projected growth in the market also highlights the importance of innovation and development within the tire industry, as manufacturers strive to create products that offer enhanced performance, safety, and sustainability. The market's expansion is further supported by the growing emphasis on cost-effective solutions and the need to reduce operational downtime in mining operations. As a result, the Global Mining Truck Tire Market is poised for significant growth, providing opportunities for manufacturers, suppliers, and other stakeholders to capitalize on the increasing demand for advanced tire solutions.

| Report Metric | Details |

| Report Name | Mining Truck Tire Market |

| Accounted market size in year | US$ 162 million |

| Forecasted market size in 2031 | US$ 215 million |

| CAGR | 4.2% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| by Type |

|

| by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Camso, Titan, Continental, Trelleborg, Michelin, Aichi, Mitas, Advance, Hankook |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |