What is Global Knife Heat Treatment Service Market?

The Global Knife Heat Treatment Service Market is a specialized segment within the broader heat treatment industry, focusing on enhancing the properties of knives through various thermal processes. Heat treatment is a critical step in knife manufacturing, as it significantly influences the performance, durability, and longevity of the blades. This market caters to a wide range of knife types, including industrial, kitchen, hunting, and tactical knives, each requiring specific treatment techniques to meet their unique demands. The services offered in this market include processes like annealing, hardening, tempering, quenching, and normalizing, each contributing to the knife's final characteristics. As the demand for high-quality knives continues to grow across different sectors, the need for advanced heat treatment services becomes increasingly important. This market is driven by technological advancements, increasing consumer awareness about knife quality, and the rising demand for customized knife solutions. Companies operating in this space are continually innovating to offer more efficient and effective heat treatment solutions, ensuring that knives meet the highest standards of performance and reliability. The Global Knife Heat Treatment Service Market is poised for growth as it adapts to the evolving needs of its diverse clientele.

Annealing, Hardening, Tempering, Quenching, Normalizing in the Global Knife Heat Treatment Service Market:

Annealing, hardening, tempering, quenching, and normalizing are fundamental processes in the Global Knife Heat Treatment Service Market, each playing a crucial role in determining the final properties of a knife. Annealing is a process that involves heating the knife material to a specific temperature and then allowing it to cool slowly. This process softens the metal, making it more workable and relieving internal stresses. It is particularly useful in preparing the metal for further shaping and machining. Hardening, on the other hand, involves heating the knife to a high temperature and then rapidly cooling it, usually in oil or water. This process increases the hardness and strength of the blade, making it more resistant to wear and tear. However, hardening can also make the metal brittle, which is where tempering comes into play. Tempering is a subsequent process that involves reheating the hardened knife to a lower temperature and then cooling it again. This reduces the brittleness while maintaining the hardness, resulting in a more balanced and durable blade. Quenching is closely related to hardening and involves the rapid cooling of the knife after it has been heated. The choice of quenching medium, such as oil, water, or air, can significantly affect the final properties of the knife. Quenching is critical for achieving the desired hardness and strength but must be carefully controlled to avoid warping or cracking. Normalizing is another heat treatment process that involves heating the knife to a specific temperature and then allowing it to cool in air. This process refines the grain structure of the metal, improving its toughness and making it more uniform. Normalizing is often used to prepare the knife for further heat treatment processes, ensuring consistent and reliable results. Each of these processes is integral to the Global Knife Heat Treatment Service Market, as they collectively contribute to the production of high-quality knives that meet the diverse needs of consumers. By understanding and applying these techniques, manufacturers can enhance the performance and longevity of their products, ensuring customer satisfaction and driving market growth.

Industrial knives, Kitchen knives, Hunting knives, Tactical knives, Other in the Global Knife Heat Treatment Service Market:

The Global Knife Heat Treatment Service Market plays a vital role in various sectors, including industrial knives, kitchen knives, hunting knives, tactical knives, and others. In the industrial sector, knives are used for cutting, slicing, and shaping materials in manufacturing processes. These knives require precise heat treatment to ensure they can withstand the rigors of industrial use, including high-speed operations and exposure to harsh environments. The heat treatment process enhances the hardness and durability of industrial knives, ensuring they maintain their sharpness and effectiveness over time. In the kitchen, knives are essential tools for chefs and home cooks alike. The heat treatment of kitchen knives focuses on achieving a balance between sharpness and ease of maintenance. A well-treated kitchen knife will retain its edge longer and resist corrosion, making it a reliable tool for food preparation. Hunting knives, on the other hand, require a different set of characteristics. These knives must be robust and capable of withstanding outdoor conditions. Heat treatment processes for hunting knives focus on enhancing toughness and edge retention, ensuring they perform well in field conditions. Tactical knives, used by military and law enforcement personnel, demand the highest standards of performance. The heat treatment of tactical knives aims to maximize strength, durability, and resistance to wear and tear. These knives must perform reliably in critical situations, making their heat treatment a crucial aspect of their manufacturing. Other types of knives, such as those used in sports or recreational activities, also benefit from specialized heat treatment processes. Each application has unique requirements, and the Global Knife Heat Treatment Service Market is equipped to meet these diverse needs. By providing tailored heat treatment solutions, this market ensures that knives across all sectors deliver optimal performance and reliability.

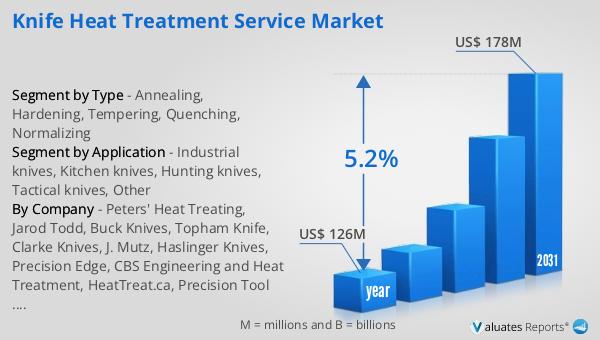

Global Knife Heat Treatment Service Market Outlook:

In 2024, the Global Knife Heat Treatment Service Market was valued at approximately $126 million. Looking ahead, it is anticipated to grow significantly, reaching an estimated value of $178 million by 2031. This growth represents a compound annual growth rate (CAGR) of 5.2% over the forecast period. The market's expansion is driven by several factors, including the increasing demand for high-quality knives across various sectors and the continuous advancements in heat treatment technologies. As consumers become more aware of the importance of knife quality, the demand for specialized heat treatment services is expected to rise. Companies in this market are focusing on innovation and efficiency to meet the evolving needs of their customers. By offering advanced heat treatment solutions, they aim to enhance the performance and durability of knives, ensuring they meet the highest standards of quality. The projected growth of the Global Knife Heat Treatment Service Market reflects the industry's commitment to excellence and its ability to adapt to changing market dynamics. As the market continues to evolve, it will play a crucial role in supporting the production of high-performance knives that cater to a wide range of applications.

| Report Metric | Details |

| Report Name | Knife Heat Treatment Service Market |

| Accounted market size in year | US$ 126 million |

| Forecasted market size in 2031 | US$ 178 million |

| CAGR | 5.2% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| Segment by Type |

|

| Segment by Application |

|

| By Region |

|

| By Company | Peters' Heat Treating, Jarod Todd, Buck Knives, Topham Knife, Clarke Knives, J. Mutz, Haslinger Knives, Precision Edge, CBS Engineering and Heat Treatment, HeatTreat.ca, Precision Tool Group (PTG), E Stokes, Bristol Heat Treat, Phoenix Heat Treating, Hills, Intersteel, Uddeholm, Burbank Steel, Harchris |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |