What is Global Fuse Coating Services Market?

The Global Fuse Coating Services Market is a specialized sector within the broader industrial coatings industry, focusing on the application of protective and functional coatings to fuses. These coatings are essential for enhancing the performance, durability, and safety of fuses used in various applications. Fuses are critical components in electrical systems, acting as safety devices that protect circuits from overcurrent by breaking the circuit when the current exceeds a certain threshold. The coatings applied to these fuses serve multiple purposes, including improving thermal stability, enhancing electrical conductivity, and providing resistance to environmental factors such as moisture, chemicals, and temperature fluctuations. The market for fuse coating services is driven by the increasing demand for reliable and efficient electrical systems across various industries, including automotive, electronics, and energy. As industries continue to evolve and require more sophisticated electrical components, the need for advanced fuse coatings that can meet stringent performance standards is expected to grow. Companies operating in this market offer a range of coating solutions, utilizing different materials and technologies to cater to the specific needs of their clients. This market is characterized by continuous innovation, as manufacturers strive to develop coatings that offer superior performance and cost-effectiveness.

High Performance Alloys, Common Alloys in the Global Fuse Coating Services Market:

High-performance alloys and common alloys play a significant role in the Global Fuse Coating Services Market, as they are often used as base materials for fuses or as components of the coatings themselves. High-performance alloys are engineered to withstand extreme conditions, offering exceptional strength, durability, and resistance to corrosion and high temperatures. These alloys are typically used in applications where reliability and longevity are critical, such as in aerospace, defense, and high-tech electronics. In the context of fuse coatings, high-performance alloys can be used to enhance the thermal and electrical properties of the fuses, ensuring they operate effectively under demanding conditions. Common alloys, on the other hand, are more widely used due to their cost-effectiveness and versatility. These alloys, which include materials like aluminum, copper, and nickel, provide a good balance of performance and affordability, making them suitable for a wide range of applications. In the fuse coating market, common alloys are often used in combination with other materials to create coatings that offer adequate protection and performance for standard applications. The choice between high-performance and common alloys depends on the specific requirements of the application, including factors such as operating environment, performance standards, and budget constraints. Companies in the fuse coating market must carefully consider these factors when selecting materials for their coatings, as the right choice can significantly impact the performance and lifespan of the fuses. The development of new alloys and coating technologies is an ongoing process, with researchers and manufacturers constantly seeking ways to improve the properties and performance of these materials. This includes efforts to enhance the conductivity, thermal stability, and environmental resistance of the coatings, as well as to reduce costs and improve manufacturing efficiency. As the demand for more advanced and reliable electrical systems continues to grow, the role of high-performance and common alloys in the fuse coating market is likely to become increasingly important. Companies that can successfully leverage these materials to create innovative and effective coating solutions will be well-positioned to capitalize on the opportunities in this dynamic market.

Paper Industry, Defence, Military, Others in the Global Fuse Coating Services Market:

The Global Fuse Coating Services Market finds applications in various industries, including the paper industry, defense, military, and others, each with its unique requirements and challenges. In the paper industry, fuses are used in machinery and equipment that require reliable electrical systems to ensure smooth and efficient operations. The coatings applied to these fuses must provide excellent thermal and electrical conductivity, as well as resistance to moisture and chemicals commonly found in paper manufacturing environments. By enhancing the performance and durability of fuses, these coatings help minimize downtime and maintenance costs, contributing to increased productivity and profitability for paper manufacturers. In the defense and military sectors, the demand for high-performance fuse coatings is driven by the need for reliable and robust electrical systems that can withstand harsh conditions and extreme environments. Fuses used in military applications must meet stringent performance standards, as any failure could have serious consequences. Coatings for these fuses are designed to provide superior protection against corrosion, temperature fluctuations, and mechanical stress, ensuring the safety and effectiveness of military equipment and systems. Other industries that utilize fuse coating services include automotive, electronics, and energy, where the need for efficient and reliable electrical systems is paramount. In the automotive industry, for example, fuses are used in various electrical components, from lighting and infotainment systems to advanced driver-assistance systems (ADAS). The coatings applied to these fuses must offer excellent thermal and electrical performance, as well as resistance to vibration and mechanical stress. In the electronics industry, fuses are used in a wide range of devices and systems, from consumer electronics to industrial equipment. The coatings for these fuses must provide reliable protection against environmental factors such as moisture, dust, and temperature fluctuations, ensuring the longevity and performance of the devices. In the energy sector, fuses are used in power generation, transmission, and distribution systems, where they play a critical role in ensuring the safety and reliability of the electrical grid. The coatings for these fuses must offer excellent thermal and electrical conductivity, as well as resistance to environmental factors such as moisture, chemicals, and temperature fluctuations. By providing reliable and efficient fuse coatings, companies in the Global Fuse Coating Services Market help ensure the safety and performance of electrical systems across various industries, contributing to the overall growth and development of these sectors.

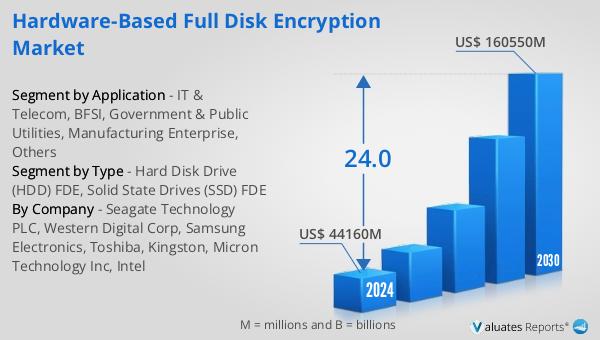

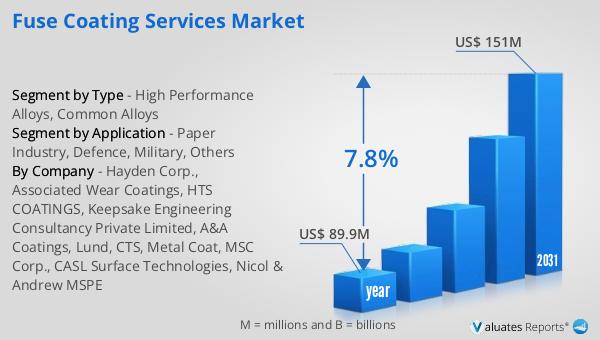

Global Fuse Coating Services Market Outlook:

In 2024, the global market for Fuse Coating Services was valued at approximately $89.9 million. This market is anticipated to experience significant growth over the coming years, with projections indicating that it will reach an estimated size of $151 million by 2031. This growth trajectory represents a compound annual growth rate (CAGR) of 7.8% during the forecast period. The increasing demand for reliable and efficient electrical systems across various industries is a key driver of this market expansion. As industries continue to evolve and require more sophisticated electrical components, the need for advanced fuse coatings that can meet stringent performance standards is expected to grow. Companies operating in this market are focusing on developing innovative coating solutions that offer superior performance and cost-effectiveness, in order to capitalize on the opportunities presented by this growing demand. The market is characterized by continuous innovation, as manufacturers strive to develop coatings that offer superior performance and cost-effectiveness. This includes efforts to enhance the conductivity, thermal stability, and environmental resistance of the coatings, as well as to reduce costs and improve manufacturing efficiency. As the demand for more advanced and reliable electrical systems continues to grow, the role of high-performance and common alloys in the fuse coating market is likely to become increasingly important. Companies that can successfully leverage these materials to create innovative and effective coating solutions will be well-positioned to capitalize on the opportunities in this dynamic market.

| Report Metric | Details |

| Report Name | Fuse Coating Services Market |

| Accounted market size in year | US$ 89.9 million |

| Forecasted market size in 2031 | US$ 151 million |

| CAGR | 7.8% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| Segment by Type |

|

| Segment by Application |

|

| By Region |

|

| By Company | Hayden Corp., Associated Wear Coatings, HTS COATINGS, Keepsake Engineering Consultancy Private Limited, A&A Coatings, Lund, CTS, Metal Coat, MSC Corp., CASL Surface Technologies, Nicol & Andrew MSPE |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |