What is Global Dip Pretreatment System Market?

The Global Dip Pretreatment System Market refers to the industry focused on the development, production, and distribution of systems used to prepare surfaces for coating or painting. These systems are essential in various manufacturing processes, as they ensure that surfaces are clean, free of contaminants, and ready for subsequent treatments. The market encompasses a range of technologies and solutions designed to enhance the adhesion and durability of coatings applied to different materials. Dip pretreatment systems are particularly valued for their efficiency and effectiveness in handling large volumes of parts, making them a preferred choice in industries such as automotive, aerospace, and consumer goods. The global market is driven by the increasing demand for high-quality finishes and the need for efficient production processes. As industries continue to evolve and seek more sustainable and cost-effective solutions, the dip pretreatment system market is expected to grow, offering innovative technologies that meet the diverse needs of manufacturers worldwide. The market's growth is also influenced by advancements in technology, which have led to the development of more sophisticated and environmentally friendly pretreatment solutions.

Manual Dip Pretreatment System, Automatic Dip Pretreatment System in the Global Dip Pretreatment System Market:

The Global Dip Pretreatment System Market is characterized by two main types of systems: Manual Dip Pretreatment Systems and Automatic Dip Pretreatment Systems. Manual Dip Pretreatment Systems are typically used in smaller operations or where customization and flexibility are required. These systems rely on human operators to manage the dipping process, which involves immersing parts into a series of chemical baths to clean and prepare surfaces for coating. The manual approach allows for greater control over the process, making it ideal for applications where precision is crucial. However, it can be labor-intensive and may not be suitable for high-volume production due to its slower pace and reliance on skilled operators. On the other hand, Automatic Dip Pretreatment Systems are designed for larger-scale operations where efficiency and consistency are paramount. These systems utilize automated machinery to handle the dipping process, significantly reducing the need for manual intervention. Automatic systems are equipped with advanced controls and sensors that ensure precise and uniform treatment of parts, making them ideal for industries with high production demands such as automotive and aerospace. The automation of the process not only enhances productivity but also minimizes the risk of human error, leading to improved quality and reduced waste. Additionally, automatic systems often incorporate features such as real-time monitoring and data collection, allowing manufacturers to optimize their processes and achieve greater operational efficiency. Both manual and automatic dip pretreatment systems play a crucial role in the Global Dip Pretreatment System Market, catering to the diverse needs of manufacturers across various industries. While manual systems offer flexibility and control, automatic systems provide speed and consistency, making them suitable for different production environments. As the market continues to evolve, manufacturers are increasingly adopting automatic systems to meet the growing demand for high-quality finishes and efficient production processes. The choice between manual and automatic systems ultimately depends on the specific requirements of the application, including factors such as production volume, complexity, and desired level of automation.

Industrial, Automobile, Home Appliances, Steel Furniture, Others in the Global Dip Pretreatment System Market:

The Global Dip Pretreatment System Market finds extensive usage across various sectors, including industrial, automotive, home appliances, steel furniture, and others. In the industrial sector, dip pretreatment systems are essential for preparing metal surfaces before painting or coating. These systems ensure that surfaces are free of contaminants, enhancing the adhesion and durability of the applied coatings. Industries such as aerospace, electronics, and heavy machinery rely on these systems to achieve high-quality finishes that meet stringent performance standards. In the automotive industry, dip pretreatment systems are crucial for preparing car bodies and components for painting. The systems ensure that surfaces are clean and free of impurities, which is vital for achieving a smooth and durable finish. The automotive sector's demand for high-quality coatings and efficient production processes drives the adoption of advanced dip pretreatment systems. Home appliances manufacturers also utilize dip pretreatment systems to prepare metal surfaces for coating. These systems help ensure that appliances have a durable and aesthetically pleasing finish, which is essential for consumer satisfaction. The use of dip pretreatment systems in this sector is driven by the need for high-quality finishes and the desire to enhance the longevity of products. In the steel furniture industry, dip pretreatment systems are used to prepare metal surfaces for painting or powder coating. These systems help ensure that furniture has a smooth and durable finish, which is crucial for both aesthetic appeal and longevity. The demand for high-quality finishes in the furniture industry drives the adoption of dip pretreatment systems. Other sectors, such as consumer electronics and construction, also benefit from the use of dip pretreatment systems. These systems help ensure that products have a high-quality finish that meets performance and aesthetic standards. As industries continue to evolve and seek more efficient and sustainable production processes, the demand for dip pretreatment systems is expected to grow. The versatility and effectiveness of these systems make them an essential component of modern manufacturing processes across various sectors.

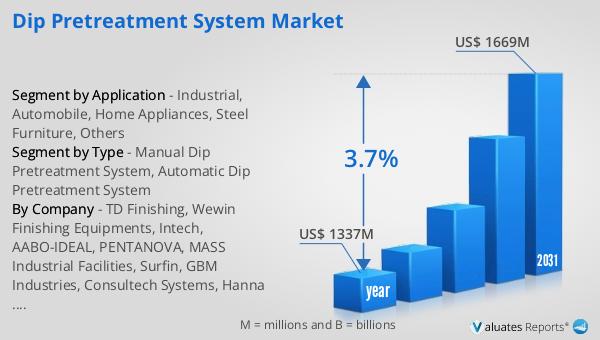

Global Dip Pretreatment System Market Outlook:

The outlook for the Global Dip Pretreatment System Market indicates a promising future, with the market valued at approximately $1,337 million in 2024. It is anticipated to expand to a revised size of around $1,669 million by 2031, reflecting a compound annual growth rate (CAGR) of 3.7% over the forecast period. This growth trajectory underscores the increasing demand for efficient and high-quality surface preparation solutions across various industries. The market's expansion is driven by the need for advanced technologies that enhance the adhesion and durability of coatings, as well as the growing emphasis on sustainable and cost-effective production processes. As manufacturers continue to seek innovative solutions to meet the evolving demands of their industries, the dip pretreatment system market is poised to offer a range of cutting-edge technologies that cater to diverse applications. The projected growth also highlights the importance of dip pretreatment systems in achieving high-quality finishes and optimizing production efficiency. With advancements in technology and a focus on sustainability, the market is expected to continue its upward trajectory, providing manufacturers with the tools they need to succeed in an increasingly competitive landscape.

| Report Metric | Details |

| Report Name | Dip Pretreatment System Market |

| Accounted market size in year | US$ 1337 million |

| Forecasted market size in 2031 | US$ 1669 million |

| CAGR | 3.7% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| Segment by Type |

|

| Segment by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | TD Finishing, Wewin Finishing Equipments, Intech, AABO-IDEAL, PENTANOVA, MASS Industrial Facilities, Surfin, GBM Industries, Consultech Systems, Hanna Technology, Color Powder Coating Equipment, AFOTEK |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |