What is Global Dental 3D Printing Solution Market?

The Global Dental 3D Printing Solution Market is a rapidly evolving sector that leverages advanced 3D printing technology to revolutionize dental care. This market encompasses a wide range of applications, including the production of dental implants, crowns, bridges, dentures, and orthodontic appliances. By utilizing 3D printing, dental professionals can create highly accurate and customized dental products that fit the unique anatomical features of each patient. This technology not only enhances the precision and quality of dental products but also significantly reduces the time and cost associated with traditional manufacturing methods. The market is driven by the increasing demand for personalized dental care, advancements in 3D printing materials and technology, and the growing awareness of the benefits of digital dentistry. As a result, dental professionals and patients alike are increasingly adopting 3D printing solutions to improve treatment outcomes and patient satisfaction. The Global Dental 3D Printing Solution Market is poised for significant growth as it continues to transform the dental industry by offering innovative and efficient solutions for dental care.

Software, Hardware in the Global Dental 3D Printing Solution Market:

In the realm of the Global Dental 3D Printing Solution Market, both software and hardware play pivotal roles in the seamless execution of dental 3D printing processes. Starting with software, it serves as the backbone of the entire 3D printing workflow. Dental professionals rely on sophisticated software solutions to design and customize dental products with precision. These software tools enable the creation of digital models of dental structures, allowing for accurate simulations and modifications before the actual printing process begins. Advanced software solutions offer features such as automated design, virtual simulations, and real-time adjustments, ensuring that the final product meets the specific requirements of each patient. Moreover, software solutions facilitate the integration of digital workflows, enabling seamless communication and collaboration between dental professionals, laboratories, and manufacturers. This integration enhances efficiency, reduces errors, and accelerates the overall production process. On the hardware front, 3D printers are the physical devices that bring digital designs to life. These printers utilize various technologies, such as stereolithography (SLA), digital light processing (DLP), and fused deposition modeling (FDM), to create dental products layer by layer. Each technology offers unique advantages in terms of speed, accuracy, and material compatibility. For instance, SLA and DLP printers are known for their high precision and ability to produce intricate details, making them ideal for creating dental crowns and bridges. On the other hand, FDM printers are valued for their versatility and cost-effectiveness, making them suitable for producing larger dental models and prototypes. The choice of hardware depends on the specific requirements of the dental application, such as the desired level of detail, material properties, and production volume. Additionally, advancements in printer technology have led to the development of multi-material and multi-color printers, allowing for the creation of complex dental products with varying material properties and aesthetics. This capability is particularly beneficial for producing dental prosthetics that closely mimic the appearance and function of natural teeth. Furthermore, the integration of artificial intelligence and machine learning algorithms into 3D printing hardware has enhanced the automation and efficiency of the printing process. These technologies enable real-time monitoring and optimization of printing parameters, ensuring consistent quality and reducing the likelihood of errors. In summary, the synergy between software and hardware in the Global Dental 3D Printing Solution Market is instrumental in delivering high-quality, customized dental products. The continuous advancements in both domains are driving the adoption of 3D printing solutions in the dental industry, ultimately improving patient outcomes and transforming the way dental care is delivered.

Orthodontic Appliance Manufacturer, Laboratory, Hospitals and Dental Clinics, Others in the Global Dental 3D Printing Solution Market:

The Global Dental 3D Printing Solution Market finds extensive applications across various sectors, including orthodontic appliance manufacturers, laboratories, hospitals, dental clinics, and others. In the realm of orthodontic appliance manufacturing, 3D printing technology has revolutionized the production of custom orthodontic devices such as aligners, retainers, and braces. By utilizing 3D printing, manufacturers can create highly precise and personalized appliances that fit the unique dental anatomy of each patient. This not only enhances the effectiveness of orthodontic treatments but also reduces the time and cost associated with traditional manufacturing methods. Additionally, 3D printing enables rapid prototyping and iterative design, allowing manufacturers to quickly develop and refine new orthodontic products. In dental laboratories, 3D printing has become an indispensable tool for producing a wide range of dental products, including crowns, bridges, dentures, and surgical guides. The ability to create highly accurate and detailed dental models has significantly improved the quality and precision of laboratory work. Dental technicians can now produce complex dental restorations with greater efficiency and consistency, leading to improved patient outcomes. Moreover, the integration of digital workflows in laboratories has streamlined communication and collaboration with dental professionals, ensuring that the final products meet the specific requirements of each patient. Hospitals and dental clinics are also leveraging 3D printing technology to enhance patient care and treatment outcomes. In hospitals, 3D printing is used to create patient-specific surgical guides and models, aiding in pre-surgical planning and improving the accuracy of complex dental surgeries. This technology allows surgeons to visualize and simulate procedures before the actual surgery, reducing the risk of complications and improving surgical precision. In dental clinics, 3D printing enables the on-site production of dental restorations, reducing the need for multiple patient visits and expediting the treatment process. Patients can receive customized dental products in a shorter timeframe, enhancing their overall experience and satisfaction. Beyond these sectors, the Global Dental 3D Printing Solution Market is also finding applications in research and education. Dental schools and research institutions are utilizing 3D printing to create educational models and conduct studies on dental materials and techniques. This technology provides students and researchers with valuable hands-on experience and insights into the latest advancements in digital dentistry. In conclusion, the Global Dental 3D Printing Solution Market is transforming the dental industry by offering innovative solutions across various sectors. The adoption of 3D printing technology is enhancing the precision, efficiency, and customization of dental products, ultimately improving patient care and treatment outcomes.

Global Dental 3D Printing Solution Market Outlook:

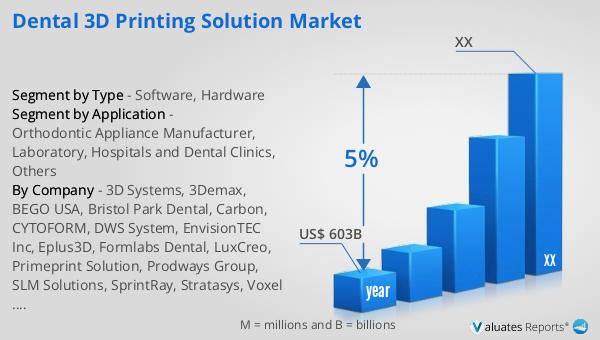

Based on our analysis, the worldwide market for medical devices is projected to reach approximately $603 billion in 2023, with an anticipated growth rate of 5% annually over the next six years. This growth trajectory underscores the increasing demand for advanced medical technologies and solutions across the globe. The medical device industry encompasses a wide range of products, including diagnostic equipment, surgical instruments, and therapeutic devices, all of which play a crucial role in modern healthcare. The steady growth rate reflects the continuous advancements in medical technology, as well as the rising prevalence of chronic diseases and the aging global population. As healthcare systems strive to improve patient outcomes and reduce costs, the demand for innovative and efficient medical devices is expected to rise. Additionally, the integration of digital technologies, such as artificial intelligence and the Internet of Things, is further driving the evolution of the medical device market. These technologies enable the development of smart and connected devices that enhance patient monitoring, diagnosis, and treatment. As a result, the global medical device market is poised for sustained growth, offering significant opportunities for innovation and investment in the coming years.

| Report Metric | Details |

| Report Name | Dental 3D Printing Solution Market |

| Accounted market size in year | US$ 603 billion |

| CAGR | 5% |

| Base Year | year |

| Segment by Type |

|

| Segment by Application |

|

| By Region |

|

| By Company | 3D Systems, 3Demax, BEGO USA, Bristol Park Dental, Carbon, CYTOFORM, DWS System, EnvisionTEC Inc, Eplus3D, Formlabs Dental, LuxCreo, Primeprint Solution, Prodways Group, SLM Solutions, SprintRay, Stratasys, Voxel Dental, Xact Metal |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |