What is Global CMP Silica Slurry Market?

The Global CMP Silica Slurry Market is a specialized segment within the semiconductor industry, focusing on the production and application of silica-based slurries used in chemical mechanical planarization (CMP) processes. CMP is a critical step in semiconductor manufacturing, where it is used to smooth and flatten the surfaces of silicon wafers, ensuring the precision and functionality of electronic components. Silica slurry, a suspension of fine silica particles in a liquid medium, plays a vital role in this process by providing the abrasive action needed to achieve the desired surface finish. The market for CMP silica slurry is driven by the increasing demand for semiconductors, which are essential components in a wide range of electronic devices, from smartphones to advanced computing systems. As technology advances and the need for smaller, more efficient chips grows, the demand for high-quality CMP silica slurry is expected to rise. This market is characterized by continuous innovation, with manufacturers striving to develop slurries that offer improved performance, reduced defect rates, and compatibility with new materials and technologies. The global reach of this market reflects the widespread adoption of semiconductor technology across various industries, highlighting its importance in the modern technological landscape.

Colloidal Silica Slurry, Fumed Silica Slurry in the Global CMP Silica Slurry Market:

Colloidal silica slurry and fumed silica slurry are two primary types of silica slurries used in the Global CMP Silica Slurry Market, each with distinct characteristics and applications. Colloidal silica slurry consists of silica particles suspended in a liquid, typically water, forming a stable colloidal system. These particles are usually spherical and have a uniform size distribution, which contributes to the slurry's effectiveness in achieving a smooth and defect-free surface during the CMP process. Colloidal silica slurries are favored for their stability, ease of handling, and ability to produce high-quality finishes on silicon wafers. They are particularly effective in applications requiring precise control over the removal rate and surface finish, making them ideal for advanced semiconductor manufacturing processes. On the other hand, fumed silica slurry is composed of silica particles produced through the flame hydrolysis of silicon tetrachloride. These particles are typically smaller and have a higher surface area compared to colloidal silica, resulting in a more aggressive abrasive action. Fumed silica slurries are often used in applications where a higher removal rate is required, such as in the initial stages of wafer planarization. The choice between colloidal and fumed silica slurries depends on the specific requirements of the CMP process, including the type of material being polished, the desired surface finish, and the overall process efficiency. Both types of slurries are integral to the CMP process, contributing to the production of high-performance semiconductor devices. As the semiconductor industry continues to evolve, the development of new slurry formulations and technologies is expected to enhance the capabilities and applications of both colloidal and fumed silica slurries, ensuring their continued relevance in the market.

Silicon Wafer Slurry, SiC Wafer Slurry, IC CMP Slurry, Others in the Global CMP Silica Slurry Market:

The Global CMP Silica Slurry Market finds extensive usage in various areas, including silicon wafer slurry, SiC wafer slurry, IC CMP slurry, and others. Silicon wafer slurry is a critical component in the production of silicon wafers, which serve as the foundation for most semiconductor devices. The slurry is used to polish and planarize the wafer surface, ensuring a smooth and defect-free finish that is essential for the subsequent fabrication of electronic components. The demand for silicon wafer slurry is driven by the increasing production of semiconductors, which are used in a wide range of electronic devices, from consumer electronics to industrial applications. SiC wafer slurry, on the other hand, is used in the production of silicon carbide (SiC) wafers, which are known for their superior thermal and electrical properties. SiC wafers are used in high-power and high-frequency applications, such as electric vehicles and renewable energy systems, where they offer improved performance and efficiency compared to traditional silicon wafers. The use of SiC wafer slurry is expected to grow as the demand for these advanced applications increases. IC CMP slurry is used in the fabrication of integrated circuits (ICs), where it plays a crucial role in achieving the precise surface finish required for the complex and densely packed structures of modern ICs. The demand for IC CMP slurry is driven by the continuous advancement of semiconductor technology, which requires increasingly sophisticated manufacturing processes. In addition to these specific applications, CMP silica slurry is also used in other areas, such as the production of MEMS (micro-electromechanical systems) and optoelectronic devices, where it contributes to the precision and performance of these advanced technologies. The versatility and effectiveness of CMP silica slurry make it an indispensable component in the semiconductor manufacturing process, supporting the production of a wide range of electronic devices and systems.

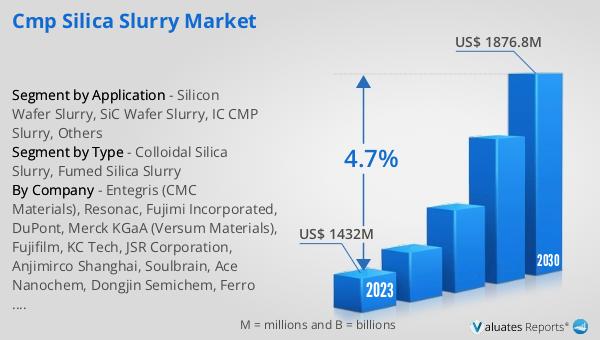

Global CMP Silica Slurry Market Outlook:

The global market for CMP Silica Slurry was valued at $1,586 million in 2024 and is anticipated to expand to a revised size of $2,794 million by 2031, reflecting a compound annual growth rate (CAGR) of 8.6% over the forecast period. This growth is indicative of the increasing demand for high-quality semiconductor components, driven by advancements in technology and the proliferation of electronic devices. In parallel, the global semiconductor market was valued at $526.8 billion in 2023 and is projected to reach $780.7 billion by 2030, underscoring the critical role of semiconductors in the modern economy. The semiconductor wafers market, a key segment within this industry, was estimated at $14.3 billion in 2023 and is expected to grow to $22.0 billion by 2030. This growth is fueled by the need for more efficient and powerful semiconductor devices, which in turn drives the demand for advanced CMP silica slurry solutions. Additionally, the global semiconductor manufacturing wafer fabrication market is projected to grow from $251.7 billion in 2023 to $506.5 billion by 2030, with a remarkable CAGR of 40.49% during the forecast period. This rapid expansion highlights the increasing complexity and sophistication of semiconductor manufacturing processes, which rely heavily on high-performance CMP silica slurries to achieve the precision and quality required for cutting-edge electronic components. As the semiconductor industry continues to evolve, the Global CMP Silica Slurry Market is poised to play a pivotal role in supporting the development and production of next-generation technologies.

| Report Metric | Details |

| Report Name | CMP Silica Slurry Market |

| Accounted market size in year | US$ 1586 million |

| Forecasted market size in 2031 | US$ 2794 million |

| CAGR | 8.6% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| by Type |

|

| by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Fujifilm, Resonac, Fujimi Incorporated, DuPont, Merck KGaA, Anjimirco Shanghai, AGC, KC Tech, JSR Corporation, Soulbrain, TOPPAN INFOMEDIA, Samsung SDI, Hubei Dinglong, Saint-Gobain, Ace Nanochem, Dongjin Semichem, Vibrantz (Ferro), WEC Group, SKC (SK Enpulse), Shanghai Xinanna Electronic Technology, Zhuhai Cornerstone Technologies, Shenzhen Angshite Technology, Zhejiang Bolai Narun Electronic Materials |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |