What is Global Bismaleimide (BMI) Prepreg Systems Market?

The Global Bismaleimide (BMI) Prepreg Systems Market is a specialized segment within the advanced materials industry, focusing on the production and application of BMI prepreg systems. These systems are composed of bismaleimide resins reinforced with fibers, typically carbon or glass, to create prepregs—pre-impregnated materials ready for molding and curing. BMI prepregs are renowned for their exceptional thermal stability, mechanical strength, and resistance to moisture and chemicals, making them ideal for high-performance applications. The market is driven by the increasing demand for lightweight and durable materials in industries such as aerospace, defense, and automotive. As these sectors strive for greater efficiency and performance, BMI prepregs offer a solution that meets stringent requirements for strength and durability while reducing weight. The market's growth is further fueled by technological advancements and innovations in manufacturing processes, which enhance the properties and applications of BMI prepregs. As a result, the Global Bismaleimide (BMI) Prepreg Systems Market is poised for significant expansion, driven by the continuous pursuit of advanced materials that meet the evolving needs of high-tech industries.

Autoclave Prepreg, Out-of-Autoclave Prepreg in the Global Bismaleimide (BMI) Prepreg Systems Market:

Autoclave prepreg and out-of-autoclave (OOA) prepreg are two distinct processing methods within the Global Bismaleimide (BMI) Prepreg Systems Market, each offering unique advantages and applications. Autoclave prepreg involves the use of an autoclave, a high-pressure vessel, to cure the prepreg materials. This method is renowned for producing components with superior mechanical properties and surface finishes due to the high pressure and temperature applied during the curing process. The autoclave method is particularly favored in industries where precision and performance are paramount, such as aerospace and defense. The high-pressure environment ensures that the prepreg layers are compacted tightly, minimizing voids and defects, which is crucial for structural integrity and performance. However, the autoclave process can be costly and time-consuming, requiring significant energy and infrastructure investment. On the other hand, out-of-autoclave (OOA) prepreg offers a more flexible and cost-effective alternative. OOA prepregs are designed to cure at lower pressures and temperatures, eliminating the need for an autoclave. This method allows for greater versatility in manufacturing, as it can be performed with simpler equipment and in less controlled environments. OOA prepregs are particularly advantageous for producing large or complex components that may not fit within an autoclave or where the cost of autoclave processing is prohibitive. The OOA process also reduces energy consumption and production costs, making it an attractive option for industries looking to optimize efficiency and sustainability. Despite the differences in processing, both autoclave and OOA prepregs share the fundamental benefits of BMI materials, including high thermal stability, excellent mechanical properties, and resistance to harsh environmental conditions. These characteristics make them suitable for a wide range of applications, from aircraft components to automotive parts and beyond. The choice between autoclave and OOA prepreg often depends on the specific requirements of the application, including the desired performance characteristics, production volume, and cost considerations. In the Global Bismaleimide (BMI) Prepreg Systems Market, the adoption of autoclave and OOA prepregs is influenced by several factors, including technological advancements, industry standards, and environmental considerations. As industries continue to seek materials that offer a balance of performance, cost, and sustainability, both autoclave and OOA prepregs are expected to play a crucial role in meeting these demands. The ongoing development of new resin formulations and fiber reinforcements further enhances the capabilities of BMI prepregs, expanding their potential applications and driving market growth. As a result, the Global Bismaleimide (BMI) Prepreg Systems Market is poised for continued innovation and expansion, with autoclave and OOA prepregs at the forefront of this dynamic industry.

Aerospace and Aviation, Defense, Others in the Global Bismaleimide (BMI) Prepreg Systems Market:

The Global Bismaleimide (BMI) Prepreg Systems Market finds extensive usage across various sectors, with aerospace and aviation, defense, and other industries being prominent consumers. In the aerospace and aviation sector, BMI prepregs are highly valued for their ability to withstand extreme temperatures and mechanical stresses. Aircraft components such as wings, fuselage sections, and engine parts benefit from the lightweight yet robust nature of BMI prepregs, which contribute to improved fuel efficiency and performance. The high thermal stability of BMI materials ensures that they can endure the harsh conditions encountered during flight, including rapid temperature changes and exposure to corrosive substances. As the aerospace industry continues to prioritize weight reduction and performance enhancement, the demand for BMI prepregs is expected to grow. In the defense sector, BMI prepregs are utilized in the production of advanced military equipment and vehicles. The superior mechanical properties and resistance to environmental factors make BMI prepregs ideal for applications such as armor, missile casings, and structural components of military aircraft and naval vessels. The ability to maintain structural integrity under extreme conditions is crucial for defense applications, where reliability and performance are paramount. BMI prepregs offer a combination of strength, durability, and lightweight characteristics that meet the stringent requirements of defense applications, contributing to enhanced operational capabilities and mission success. Beyond aerospace and defense, BMI prepregs are also used in other industries that demand high-performance materials. The automotive industry, for example, benefits from the lightweight and durable nature of BMI prepregs in the production of high-performance vehicles and components. The use of BMI prepregs in automotive applications can lead to improved fuel efficiency and reduced emissions, aligning with the industry's goals for sustainability and environmental responsibility. Additionally, BMI prepregs are employed in the production of sports equipment, industrial machinery, and electronic components, where their unique properties offer advantages in terms of performance and longevity. The versatility and performance of BMI prepregs make them a valuable asset across multiple industries, driving their adoption and market growth. As technological advancements continue to enhance the properties and applications of BMI prepregs, their usage is expected to expand further, meeting the evolving needs of high-tech industries. The Global Bismaleimide (BMI) Prepreg Systems Market is poised for continued growth, driven by the increasing demand for advanced materials that offer a balance of performance, cost, and sustainability.

Global Bismaleimide (BMI) Prepreg Systems Market Outlook:

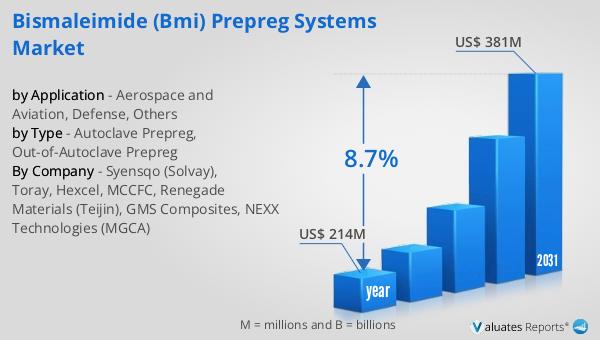

The global market for Bismaleimide (BMI) Prepreg Systems was valued at $214 million in 2024, and it is anticipated to grow significantly, reaching an estimated size of $381 million by 2031. This growth trajectory represents a compound annual growth rate (CAGR) of 8.7% over the forecast period. The market's expansion is driven by the increasing demand for high-performance materials across various industries, including aerospace, defense, and automotive. BMI prepregs offer a unique combination of thermal stability, mechanical strength, and resistance to harsh environmental conditions, making them ideal for applications that require durability and reliability. As industries continue to prioritize efficiency and performance, the adoption of BMI prepregs is expected to rise, contributing to the market's growth. Technological advancements and innovations in manufacturing processes are also playing a crucial role in the market's development. These advancements enhance the properties and applications of BMI prepregs, making them more versatile and cost-effective. As a result, the Global Bismaleimide (BMI) Prepreg Systems Market is poised for significant expansion, driven by the continuous pursuit of advanced materials that meet the evolving needs of high-tech industries. The market's growth is further supported by the increasing focus on sustainability and environmental responsibility, as BMI prepregs offer a lightweight and durable solution that aligns with these goals. Overall, the Global Bismaleimide (BMI) Prepreg Systems Market is set to experience robust growth, driven by the demand for high-performance materials and the ongoing development of new technologies and applications.

| Report Metric | Details |

| Report Name | Bismaleimide (BMI) Prepreg Systems Market |

| Accounted market size in year | US$ 214 million |

| Forecasted market size in 2031 | US$ 381 million |

| CAGR | 8.7% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| by Type |

|

| by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Syensqo (Solvay), Toray, Hexcel, MCCFC, Renegade Materials (Teijin), GMS Composites, NEXX Technologies (MGCA) |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |