What is Global Automotive Aluminum Alloy Wheels Market?

The Global Automotive Aluminum Alloy Wheels Market is a significant segment within the automotive industry, focusing on the production and distribution of wheels made from aluminum alloys. These wheels are favored for their lightweight nature, which contributes to improved fuel efficiency and enhanced vehicle performance. Aluminum alloy wheels are also known for their aesthetic appeal, offering a sleek and modern look that is popular among consumers. The market encompasses various types of wheels, including those designed for passenger vehicles and commercial vehicles, catering to a wide range of automotive needs. The demand for aluminum alloy wheels is driven by the growing emphasis on reducing vehicle weight to meet stringent emission standards and improve fuel economy. Additionally, the increasing popularity of electric vehicles, which benefit from lightweight components, further propels the market. Manufacturers in this sector are continually innovating to enhance the strength, durability, and design of aluminum alloy wheels, ensuring they meet the evolving demands of the automotive industry. As a result, the Global Automotive Aluminum Alloy Wheels Market plays a crucial role in shaping the future of automotive design and performance.

Casting, Forging, Other in the Global Automotive Aluminum Alloy Wheels Market:

In the Global Automotive Aluminum Alloy Wheels Market, the production processes of casting, forging, and other methods play a pivotal role in determining the quality and characteristics of the wheels. Casting is a widely used method where molten aluminum is poured into a mold to form the wheel. This process is cost-effective and allows for the production of complex shapes and designs. Cast wheels are generally lighter than steel wheels, offering improved fuel efficiency and handling. However, they may not be as strong as forged wheels, making them more susceptible to damage from impacts. Despite this, advancements in casting technology have led to the development of high-quality cast wheels that offer a good balance of performance and cost. Forging, on the other hand, involves shaping the aluminum alloy under high pressure, resulting in a denser and stronger wheel. Forged wheels are known for their superior strength-to-weight ratio, making them ideal for high-performance vehicles that require enhanced durability and handling. The forging process also allows for greater customization in terms of design and finish, appealing to consumers looking for unique and high-end wheel options. However, the complexity and cost of the forging process make forged wheels more expensive than their cast counterparts. Other methods in the production of aluminum alloy wheels include flow forming and rotary forging, which combine elements of casting and forging to produce wheels with improved strength and reduced weight. These methods are gaining popularity as they offer a middle ground between the cost-effectiveness of casting and the strength of forging. Flow forming, for instance, involves spinning the cast wheel while applying pressure to stretch and compress the aluminum, enhancing its structural integrity. Rotary forging, similar to traditional forging, uses rotational force to shape the wheel, resulting in a lightweight yet strong product. Each of these production methods has its own set of advantages and limitations, influencing the choice of process based on the specific requirements of the vehicle and consumer preferences. As the Global Automotive Aluminum Alloy Wheels Market continues to evolve, manufacturers are investing in research and development to refine these processes, aiming to produce wheels that offer the best combination of performance, durability, and aesthetic appeal. This ongoing innovation is crucial in meeting the diverse needs of the automotive industry and maintaining competitiveness in the market.

Passenger Vehicle, Commercial Vehicle in the Global Automotive Aluminum Alloy Wheels Market:

The usage of Global Automotive Aluminum Alloy Wheels Market in passenger vehicles and commercial vehicles highlights the versatility and importance of these components in the automotive sector. In passenger vehicles, aluminum alloy wheels are highly sought after for their lightweight properties, which contribute to improved fuel efficiency and handling. The reduced weight of aluminum alloy wheels compared to traditional steel wheels allows for better acceleration and braking performance, enhancing the overall driving experience. Additionally, the aesthetic appeal of aluminum alloy wheels is a significant factor for consumers, as they offer a modern and stylish look that complements the design of contemporary passenger vehicles. The ability to customize the design and finish of these wheels further adds to their popularity among car enthusiasts who seek to personalize their vehicles. In commercial vehicles, the use of aluminum alloy wheels is driven by the need for durability and performance. Commercial vehicles, such as trucks and buses, require wheels that can withstand heavy loads and challenging road conditions. Aluminum alloy wheels, with their superior strength-to-weight ratio, provide the necessary durability while also contributing to fuel savings due to their lighter weight. This is particularly important for fleet operators who are looking to reduce operational costs and improve the efficiency of their vehicles. Moreover, the corrosion-resistant properties of aluminum alloy wheels make them suitable for commercial vehicles that are exposed to harsh environments and long-distance travel. The ability to maintain their appearance and performance over time is a key advantage for commercial vehicle operators. As the demand for both passenger and commercial vehicles continues to grow, the Global Automotive Aluminum Alloy Wheels Market is poised to play a crucial role in meeting the diverse needs of the automotive industry. Manufacturers are focusing on developing wheels that offer the best combination of performance, durability, and design to cater to the specific requirements of different vehicle types. This includes investing in advanced production techniques and materials to enhance the quality and performance of aluminum alloy wheels. As a result, the market is expected to see continued growth and innovation, driven by the increasing demand for lightweight and high-performance wheels in both passenger and commercial vehicles.

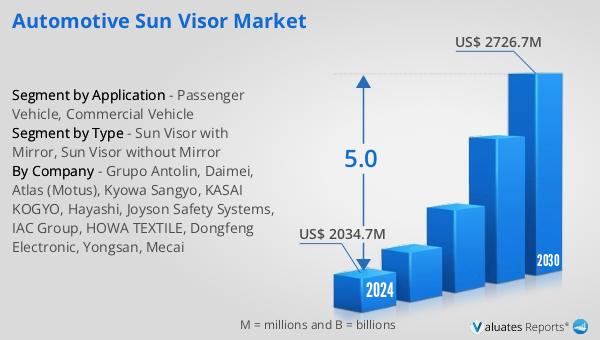

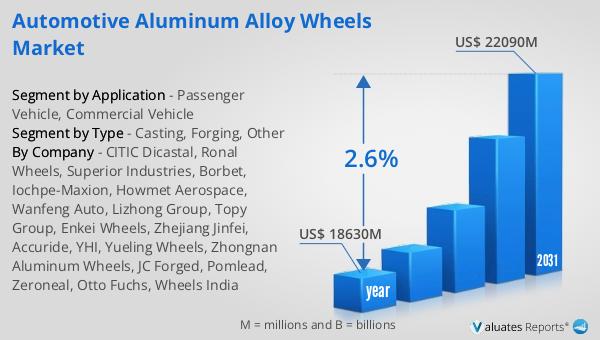

Global Automotive Aluminum Alloy Wheels Market Outlook:

The outlook for the Global Automotive Aluminum Alloy Wheels Market indicates a promising trajectory, with the market valued at approximately $18.63 billion in 2024. It is anticipated to expand to a revised size of around $22.09 billion by 2031, reflecting a compound annual growth rate (CAGR) of 2.6% over the forecast period. This growth is driven by several factors, including the increasing demand for lightweight and fuel-efficient vehicles, which has led to a rise in the adoption of aluminum alloy wheels. The automotive industry's shift towards electric vehicles, which benefit from reduced weight and improved performance, further supports this trend. Additionally, the aesthetic appeal and customization options offered by aluminum alloy wheels continue to attract consumers, contributing to market expansion. Manufacturers are also investing in research and development to enhance the strength, durability, and design of these wheels, ensuring they meet the evolving demands of the automotive sector. As a result, the Global Automotive Aluminum Alloy Wheels Market is expected to maintain its upward trajectory, playing a crucial role in shaping the future of automotive design and performance. This positive outlook underscores the importance of aluminum alloy wheels in the automotive industry and highlights the ongoing innovation and growth within this market segment.

| Report Metric | Details |

| Report Name | Automotive Aluminum Alloy Wheels Market |

| Accounted market size in year | US$ 18630 million |

| Forecasted market size in 2031 | US$ 22090 million |

| CAGR | 2.6% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| Segment by Type |

|

| Segment by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | CITIC Dicastal, Ronal Wheels, Superior Industries, Borbet, Iochpe-Maxion, Howmet Aerospace, Wanfeng Auto, Lizhong Group, Topy Group, Enkei Wheels, Zhejiang Jinfei, Accuride, YHI, Yueling Wheels, Zhongnan Aluminum Wheels, JC Forged, Pomlead, Zeroneal, Otto Fuchs, Wheels India |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |