What is Global Anode Grade Petroleum Coke Market?

The Global Anode Grade Petroleum Coke Market is a specialized segment within the broader petroleum coke industry, focusing on the production and supply of high-quality coke used primarily in the manufacturing of anodes for the aluminum industry. Anode grade petroleum coke is derived from the coking process of crude oil, where it is subjected to high temperatures to remove volatile components, resulting in a dense, carbon-rich material. This type of coke is prized for its low sulfur content and high purity, making it ideal for use in the electrolytic process of aluminum production. The market for anode grade petroleum coke is driven by the growing demand for aluminum, which is used extensively in various industries such as automotive, aerospace, and construction due to its lightweight and corrosion-resistant properties. Additionally, the market is influenced by factors such as the availability of raw materials, technological advancements in production processes, and environmental regulations that impact the production and use of petroleum coke. As industries continue to seek more efficient and sustainable materials, the demand for high-quality anode grade petroleum coke is expected to remain strong, supporting the growth of this market segment.

Needle Coke, Shot Coke, Sponge Coke, Honeycomb Coke in the Global Anode Grade Petroleum Coke Market:

Needle coke, shot coke, sponge coke, and honeycomb coke are distinct types of petroleum coke, each with unique characteristics and applications within the Global Anode Grade Petroleum Coke Market. Needle coke is a premium grade of petroleum coke known for its crystalline structure and high conductivity, making it essential in the production of graphite electrodes used in electric arc furnaces for steelmaking. Its needle-like structure allows for the efficient transfer of electricity, which is crucial in high-temperature applications. The demand for needle coke is closely tied to the steel industry, where it plays a vital role in the recycling of scrap steel and the production of new steel products. Shot coke, on the other hand, is characterized by its spherical shape and is typically considered a lower quality coke due to its higher sulfur content and lower purity. It is often used as a fuel in power generation and cement production, where its lower cost makes it an attractive option despite its environmental drawbacks. Sponge coke, named for its porous, sponge-like appearance, is another type of petroleum coke that is used primarily as a fuel source. It is valued for its high carbon content and is often used in the production of anodes for the aluminum industry, as well as in the manufacturing of titanium dioxide, a key ingredient in paints and coatings. Honeycomb coke, with its unique honeycomb structure, is less common but is used in specific applications where its structural properties are advantageous. Each type of coke has its place within the Global Anode Grade Petroleum Coke Market, with demand driven by the specific needs of industries such as aluminum, steel, and energy production. The choice of coke type depends on factors such as cost, availability, and the specific requirements of the end-use application. As industries continue to evolve and seek more efficient and sustainable materials, the role of these different types of petroleum coke in the market is likely to change, with a growing emphasis on reducing environmental impact and improving the efficiency of production processes.

Aluminum industry, Steel industry, Others in the Global Anode Grade Petroleum Coke Market:

The Global Anode Grade Petroleum Coke Market plays a crucial role in several industries, with its primary usage in the aluminum and steel industries, as well as other sectors. In the aluminum industry, anode grade petroleum coke is a key component in the production of carbon anodes, which are essential for the electrolytic reduction of alumina to produce aluminum. The high purity and low sulfur content of anode grade petroleum coke make it ideal for this application, as it ensures the efficient and cost-effective production of aluminum. The demand for aluminum continues to grow, driven by its widespread use in automotive, aerospace, and construction industries, which in turn fuels the demand for anode grade petroleum coke. In the steel industry, anode grade petroleum coke is used in the production of graphite electrodes, which are critical for the operation of electric arc furnaces. These furnaces are used to melt scrap steel and produce new steel products, making the steel industry a significant consumer of anode grade petroleum coke. The high conductivity and structural integrity of the coke are essential for the efficient operation of these furnaces, and as the steel industry continues to expand, the demand for high-quality anode grade petroleum coke is expected to increase. Beyond the aluminum and steel industries, anode grade petroleum coke is also used in other applications, such as the production of titanium dioxide, a key ingredient in paints and coatings. Its high carbon content and purity make it suitable for use in the chemical industry, where it is used as a reducing agent in various processes. Additionally, anode grade petroleum coke is used as a fuel in power generation and cement production, where its high energy content and relatively low cost make it an attractive option. As industries continue to seek more efficient and sustainable materials, the usage of anode grade petroleum coke is likely to evolve, with a growing emphasis on reducing environmental impact and improving the efficiency of production processes.

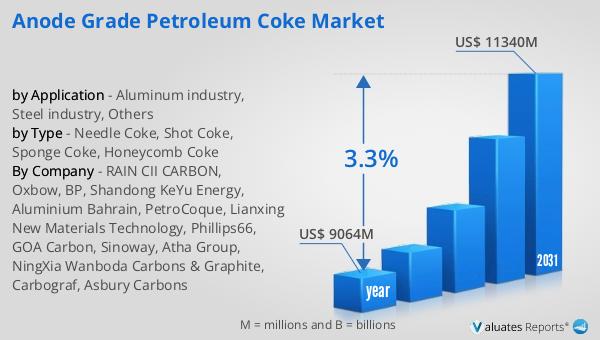

Global Anode Grade Petroleum Coke Market Outlook:

The global market for Anode Grade Petroleum Coke was valued at approximately $9,064 million in 2024. It is anticipated to grow steadily, reaching an estimated size of $11,340 million by 2031. This growth represents a compound annual growth rate (CAGR) of 3.3% over the forecast period. This steady increase in market size reflects the ongoing demand for high-quality anode grade petroleum coke, driven by its critical role in industries such as aluminum and steel production. The market's expansion is supported by the growing demand for aluminum, which is used extensively in various sectors due to its lightweight and corrosion-resistant properties. Additionally, the steel industry's reliance on graphite electrodes, produced using anode grade petroleum coke, further contributes to the market's growth. As industries continue to evolve and seek more efficient and sustainable materials, the demand for high-quality anode grade petroleum coke is expected to remain strong, supporting the growth of this market segment. The market's growth is also influenced by factors such as the availability of raw materials, technological advancements in production processes, and environmental regulations that impact the production and use of petroleum coke. As the market continues to expand, companies operating in this space are likely to focus on innovation and sustainability to meet the evolving needs of their customers and maintain their competitive edge.

| Report Metric | Details |

| Report Name | Anode Grade Petroleum Coke Market |

| Accounted market size in year | US$ 9064 million |

| Forecasted market size in 2031 | US$ 11340 million |

| CAGR | 3.3% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| by Type |

|

| by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | RAIN CII CARBON, Oxbow, BP, Shandong KeYu Energy, Aluminium Bahrain, PetroCoque, Lianxing New Materials Technology, Phillips66, GOA Carbon, Sinoway, Atha Group, NingXia Wanboda Carbons & Graphite, Carbograf, Asbury Carbons |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |