What is Global 75% Nickel Coated Graphite Market?

The Global 75% Nickel Coated Graphite Market refers to a specialized segment within the materials industry, focusing on graphite particles that are coated with a layer of nickel, constituting 75% of the composite material. This unique combination leverages the inherent properties of both nickel and graphite, resulting in a material that is highly conductive, corrosion-resistant, and mechanically robust. The nickel coating enhances the electrical conductivity of graphite while providing a protective barrier against oxidation and wear, making it suitable for various high-performance applications. Industries such as electronics, aerospace, and automotive are increasingly utilizing this material due to its ability to improve the performance and longevity of components. The market for this composite is driven by the growing demand for advanced materials that can meet the stringent requirements of modern technology and industrial applications. As industries continue to innovate and seek materials that offer superior performance, the Global 75% Nickel Coated Graphite Market is poised for significant growth, offering solutions that cater to the evolving needs of various sectors.

Spherical, Flake in the Global 75% Nickel Coated Graphite Market:

In the realm of the Global 75% Nickel Coated Graphite Market, two primary forms of this composite material are prevalent: spherical and flake. Each form offers distinct characteristics that cater to different industrial needs. Spherical nickel-coated graphite is characterized by its round, uniform particles, which provide excellent flowability and packing density. This makes it particularly suitable for applications requiring high conductivity and uniformity, such as in conductive inks and coatings. The spherical shape ensures minimal contact resistance and optimal surface coverage, enhancing the overall performance of the end product. On the other hand, flake nickel-coated graphite consists of flat, plate-like particles that offer a larger surface area compared to their spherical counterparts. This increased surface area translates to enhanced conductivity and thermal management capabilities, making flake graphite ideal for applications in thermal interface materials and electromagnetic interference (EMI) shielding. The choice between spherical and flake forms often depends on the specific requirements of the application, such as the desired level of conductivity, thermal management, and mechanical properties. In the electronics industry, for instance, spherical nickel-coated graphite is favored for its ability to provide consistent electrical pathways, while flake graphite is preferred for its superior thermal dissipation properties. The versatility of these two forms allows manufacturers to tailor their products to meet the diverse needs of various sectors, from consumer electronics to aerospace and automotive industries. As the demand for high-performance materials continues to rise, the Global 75% Nickel Coated Graphite Market is expected to expand, driven by the unique advantages offered by both spherical and flake forms. The ongoing advancements in material science and engineering are likely to further enhance the properties of these composites, opening up new possibilities for their application in cutting-edge technologies. Whether it's improving the efficiency of electronic devices or enhancing the durability of automotive components, the Global 75% Nickel Coated Graphite Market plays a crucial role in shaping the future of material innovation.

Electromagnetic Shielding Materials, Conductive Coating, Conductive Adhesive, Electronic Packaging, Others in the Global 75% Nickel Coated Graphite Market:

The Global 75% Nickel Coated Graphite Market finds extensive usage across various applications, each leveraging the unique properties of this composite material. In the realm of electromagnetic shielding materials, nickel-coated graphite is highly valued for its ability to effectively block electromagnetic interference (EMI). The nickel coating provides excellent conductivity, allowing the material to absorb and reflect electromagnetic waves, thus protecting sensitive electronic components from interference. This makes it an ideal choice for use in electronic enclosures, shielding gaskets, and other EMI-sensitive applications. In conductive coatings, the material's high conductivity and corrosion resistance make it a preferred choice for enhancing the performance of electronic devices. The nickel coating ensures a stable and reliable conductive path, improving the efficiency and longevity of the coated surfaces. Conductive adhesives also benefit from the inclusion of nickel-coated graphite, as it enhances the electrical connectivity between components while providing mechanical strength and durability. This is particularly important in applications where reliable electrical connections are critical, such as in the assembly of electronic circuits and devices. In electronic packaging, nickel-coated graphite is used to improve thermal management and electrical performance. The material's ability to conduct heat and electricity efficiently helps in dissipating heat generated by electronic components, thereby enhancing their performance and reliability. Additionally, the composite's mechanical robustness ensures that the packaging can withstand the rigors of various environmental conditions. Beyond these applications, nickel-coated graphite is also utilized in other areas such as battery electrodes, fuel cells, and sensors, where its unique combination of properties can significantly enhance performance. As industries continue to push the boundaries of technology, the demand for advanced materials like nickel-coated graphite is expected to grow, driving innovation and development across multiple sectors.

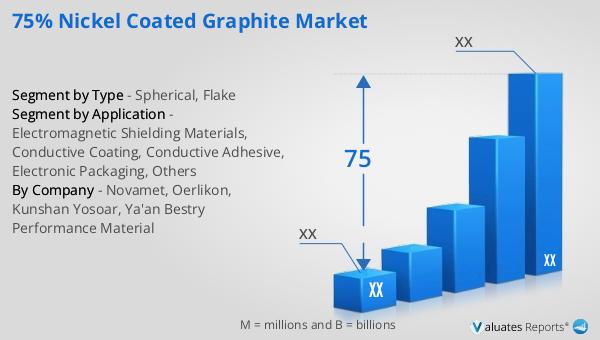

Global 75% Nickel Coated Graphite Market Outlook:

The worldwide market for 75% Nickel Coated Graphite was valued at a certain amount in 2024 and is anticipated to reach a new valuation by 2031, experiencing growth at a compound annual growth rate (CAGR) over the forecast period. In North America, the market for 75% Nickel Coated Graphite is projected to grow from its 2024 valuation to a new figure by 2031, with a CAGR spanning from 2025 to 2031. Similarly, the Asia-Pacific region is expected to see its market size increase from its 2024 valuation to a new figure by 2031, also at a CAGR during the same forecast period. Key global manufacturers in this market include Novamet, Oerlikon, Kunshan Yosoar, and Ya'an Bestry Performance Material, among others. These companies play a significant role in driving the market forward, leveraging their expertise and innovation to meet the growing demand for high-performance materials. As the market continues to evolve, these manufacturers are likely to expand their product offerings and enhance their production capabilities to cater to the diverse needs of various industries. The ongoing advancements in material science and technology are expected to further propel the growth of the Global 75% Nickel Coated Graphite Market, offering new opportunities for manufacturers and consumers alike.

| Report Metric | Details |

| Report Name | 75% Nickel Coated Graphite Market |

| CAGR | 75 |

| by Type |

|

| by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Novamet, Oerlikon, Kunshan Yosoar, Ya'an Bestry Performance Material |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |