What is Vibratory Sifting Machine - Global Market?

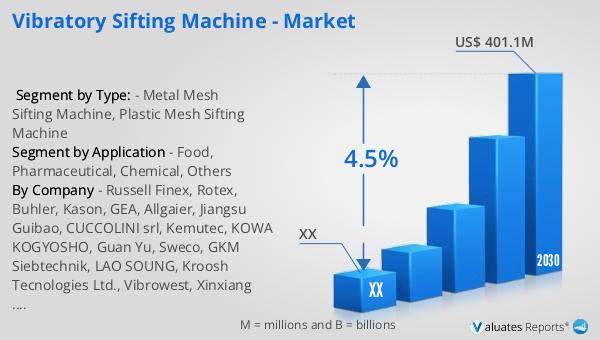

Vibratory sifting machines are essential tools in various industries for separating and classifying materials based on size and texture. These machines use vibratory motion to efficiently sift and sort materials, ensuring that only the desired particles pass through the mesh screens. The global market for vibratory sifting machines is expanding due to their widespread application in industries such as food processing, pharmaceuticals, chemicals, and more. These machines are valued for their ability to enhance product quality and consistency by removing unwanted particles and ensuring uniformity. The demand for vibratory sifting machines is driven by the need for efficient and reliable material handling solutions that can meet the stringent quality standards of various industries. As industries continue to evolve and demand higher precision in their processes, the vibratory sifting machine market is expected to grow, offering advanced features and improved efficiency to meet the diverse needs of its users. The global market for these machines was valued at approximately US$ 296 million in 2023, with projections indicating a growth to US$ 401.1 million by 2030, reflecting a compound annual growth rate (CAGR) of 4.5% during the forecast period from 2024 to 2030.

Metal Mesh Sifting Machine, Plastic Mesh Sifting Machine in the Vibratory Sifting Machine - Global Market:

Metal mesh sifting machines and plastic mesh sifting machines are two primary types of vibratory sifting machines, each offering unique advantages and applications in the global market. Metal mesh sifting machines are renowned for their durability and strength, making them ideal for heavy-duty applications where robust performance is required. These machines are often used in industries where the materials being sifted are abrasive or where high temperatures are involved, as metal meshes can withstand such conditions without degrading. The precision of metal mesh allows for accurate separation of particles, ensuring high-quality output. On the other hand, plastic mesh sifting machines are favored for their lightweight and corrosion-resistant properties. They are particularly useful in industries where contamination from metal particles must be avoided, such as in food and pharmaceuticals. Plastic meshes are also more flexible, allowing for easier handling and maintenance. The choice between metal and plastic mesh sifting machines depends largely on the specific requirements of the application, including the nature of the materials being processed and the environmental conditions. Both types of machines contribute significantly to the efficiency and effectiveness of the sifting process, ensuring that industries can maintain high standards of quality and productivity. As the global market for vibratory sifting machines continues to grow, manufacturers are focusing on developing innovative solutions that combine the strengths of both metal and plastic meshes, offering enhanced performance and versatility to meet the evolving needs of their customers. This ongoing innovation is expected to drive further growth in the market, as industries seek more efficient and reliable sifting solutions to improve their operations.

Food, Pharmaceutical, Chemical, Others in the Vibratory Sifting Machine - Global Market:

Vibratory sifting machines play a crucial role in various industries, including food, pharmaceuticals, chemicals, and others, by ensuring the quality and consistency of products. In the food industry, these machines are used to sift and sort ingredients such as flour, sugar, and spices, removing impurities and ensuring uniform particle size. This not only enhances the quality of the final product but also improves the efficiency of subsequent processing steps. In the pharmaceutical industry, vibratory sifting machines are essential for ensuring the purity and consistency of powders and granules used in the production of medications. By removing contaminants and ensuring uniform particle size, these machines help maintain the efficacy and safety of pharmaceutical products. In the chemical industry, vibratory sifting machines are used to separate and classify various chemical compounds, ensuring that only the desired particles are used in production processes. This is critical for maintaining the quality and performance of chemical products. Beyond these industries, vibratory sifting machines are also used in sectors such as agriculture, mining, and construction, where they help improve the efficiency and effectiveness of material handling processes. The versatility and reliability of vibratory sifting machines make them indispensable tools in a wide range of applications, contributing to the growth and development of the global market. As industries continue to demand higher quality and consistency in their products, the use of vibratory sifting machines is expected to increase, driving further growth in the market.

Vibratory Sifting Machine - Global Market Outlook:

The global market for vibratory sifting machines was valued at approximately US$ 296 million in 2023, with expectations to reach a revised size of US$ 401.1 million by 2030, reflecting a compound annual growth rate (CAGR) of 4.5% during the forecast period from 2024 to 2030. This growth is indicative of the increasing demand for efficient and reliable material handling solutions across various industries. In North America, the market for vibratory sifting machines was valued at a significant amount in 2023, with projections indicating continued growth through 2030. The steady increase in demand is driven by the need for advanced sifting technologies that can meet the stringent quality standards of industries such as food processing, pharmaceuticals, and chemicals. As industries continue to evolve and require higher precision in their processes, the vibratory sifting machine market is expected to expand, offering innovative solutions that enhance performance and efficiency. This growth is further supported by the ongoing development of new technologies and materials that improve the capabilities of vibratory sifting machines, ensuring that they remain a vital component of modern industrial processes. The market outlook for vibratory sifting machines is positive, with continued growth anticipated as industries seek to improve their operations and maintain high standards of quality and productivity.

| Report Metric | Details |

| Report Name | Vibratory Sifting Machine - Market |

| Forecasted market size in 2030 | US$ 401.1 million |

| CAGR | 4.5% |

| Forecasted years | 2024 - 2030 |

| Segment by Type: |

|

| Segment by Application |

|

| By Region |

|

| By Company | Russell Finex, Rotex, Buhler, Kason, GEA, Allgaier, Jiangsu Guibao, CUCCOLINI srl, Kemutec, KOWA KOGYOSHO, Guan Yu, Sweco, GKM Siebtechnik, LAO SOUNG, Kroosh Tecnologies Ltd., Vibrowest, Xinxiang Dayong, Assonic, TOYO HITEC, Gaofu, Dalton, Galaxy Sivtek, Xinxiang Hengyu |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |