What is Ultrasonic Metal Spot Welding Machine - Global Market?

The Ultrasonic Metal Spot Welding Machine is a specialized device used in various industries for joining metal parts through ultrasonic vibrations. This technology is particularly advantageous because it allows for precise and clean welds without the need for additional materials like solder or adhesives. The global market for these machines is expanding as industries seek more efficient and environmentally friendly manufacturing processes. Ultrasonic welding is known for its speed and ability to join dissimilar metals, making it a preferred choice in sectors like automotive, electronics, and medical devices. The machine operates by converting high-frequency electrical energy into mechanical vibrations, which are then applied to the metal surfaces to be joined. This process generates localized heat through friction, causing the metals to bond at a molecular level. The demand for ultrasonic metal spot welding machines is driven by the need for high-quality, reliable welds in applications where traditional welding methods may fall short. As industries continue to innovate and seek sustainable solutions, the adoption of ultrasonic welding technology is expected to grow, contributing to the overall expansion of the global market.

Handheld, Bench-top in the Ultrasonic Metal Spot Welding Machine - Global Market:

Handheld and bench-top ultrasonic metal spot welding machines are two primary types of equipment used in various industrial applications. Handheld ultrasonic welders are portable devices that offer flexibility and ease of use, making them ideal for on-site repairs and small-scale production tasks. These machines are lightweight and ergonomically designed to ensure user comfort during operation. They are commonly used in industries where mobility and quick setup are essential, such as in automotive repair shops or small electronics assembly lines. The handheld devices are equipped with a transducer, booster, and horn, which work together to deliver ultrasonic energy to the welding area. This setup allows for precise control over the welding process, ensuring consistent and high-quality results. On the other hand, bench-top ultrasonic metal spot welding machines are stationary units designed for more extensive and repetitive welding tasks. These machines are typically used in manufacturing environments where high-volume production is required. Bench-top welders offer greater power and stability compared to their handheld counterparts, making them suitable for joining thicker or more robust metal components. They are equipped with advanced features such as programmable settings, automated controls, and integrated cooling systems to enhance performance and efficiency. The bench-top machines are often used in industries like automotive manufacturing, where precision and speed are critical. Both handheld and bench-top ultrasonic welders operate on the same fundamental principle of converting electrical energy into mechanical vibrations. However, the choice between the two depends on the specific requirements of the application, such as the size and type of materials being welded, the production volume, and the desired level of automation. As the global market for ultrasonic metal spot welding machines continues to grow, manufacturers are investing in research and development to enhance the capabilities and versatility of these devices. Innovations such as digital interfaces, real-time monitoring, and energy-efficient designs are being incorporated into both handheld and bench-top models to meet the evolving needs of various industries. The increasing demand for lightweight and durable materials in sectors like automotive and electronics is also driving the adoption of ultrasonic welding technology. As a result, both handheld and bench-top ultrasonic metal spot welding machines are expected to play a significant role in the future of manufacturing, offering reliable and efficient solutions for joining metal components.

Automotive, Electronics and Battery, Medical, Packaging, Others in the Ultrasonic Metal Spot Welding Machine - Global Market:

Ultrasonic metal spot welding machines are widely used across various industries due to their ability to produce strong and precise welds without the need for additional materials. In the automotive industry, these machines are employed to join lightweight metals and alloys, which are increasingly used to improve fuel efficiency and reduce emissions. Ultrasonic welding is particularly beneficial for assembling components like wire harnesses, battery packs, and electronic modules, where traditional welding methods may cause damage or distortion. The technology ensures a clean and reliable bond, enhancing the overall performance and safety of automotive systems. In the electronics and battery sector, ultrasonic metal spot welding machines are used to connect delicate components without generating excessive heat, which could damage sensitive parts. This is crucial for manufacturing items like circuit boards, sensors, and battery terminals, where precision and reliability are paramount. The medical industry also benefits from ultrasonic welding technology, as it allows for the assembly of intricate devices and components without compromising their integrity. Medical instruments, implants, and diagnostic equipment often require precise and sterile joining methods, which ultrasonic welding can provide. In the packaging industry, ultrasonic metal spot welding machines are used to create airtight and tamper-proof seals for containers and packaging materials. This is essential for preserving the quality and safety of products, particularly in the food and pharmaceutical sectors. The ability to produce consistent and reliable seals without the use of adhesives or heat makes ultrasonic welding an attractive option for packaging manufacturers. Beyond these specific industries, ultrasonic metal spot welding machines are also utilized in various other applications, such as aerospace, telecommunications, and consumer electronics. The versatility and efficiency of ultrasonic welding technology make it a valuable tool for joining metal components in a wide range of settings. As industries continue to seek innovative and sustainable manufacturing solutions, the use of ultrasonic metal spot welding machines is expected to expand, driving further growth in the global market.

Ultrasonic Metal Spot Welding Machine - Global Market Outlook:

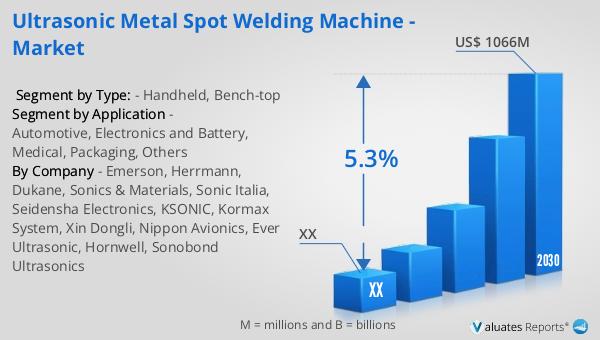

The global market for Ultrasonic Metal Spot Welding Machines was valued at approximately $743 million in 2023. It is projected to grow to a revised size of $1,066 million by 2030, reflecting a compound annual growth rate (CAGR) of 5.3% during the forecast period from 2024 to 2030. This growth is indicative of the increasing demand for efficient and environmentally friendly welding solutions across various industries. The North American market, in particular, is expected to see significant growth, although specific figures for this region were not provided. The expansion of the market can be attributed to the rising adoption of ultrasonic welding technology in sectors such as automotive, electronics, and medical devices, where precision and reliability are crucial. As industries continue to innovate and seek sustainable manufacturing processes, the demand for ultrasonic metal spot welding machines is likely to increase, contributing to the overall growth of the global market. The forecasted growth underscores the importance of ultrasonic welding technology in modern manufacturing and its potential to drive advancements in various industries.

| Report Metric | Details |

| Report Name | Ultrasonic Metal Spot Welding Machine - Market |

| Forecasted market size in 2030 | US$ 1066 million |

| CAGR | 5.3% |

| Forecasted years | 2024 - 2030 |

| Segment by Type: |

|

| Segment by Application |

|

| By Region |

|

| By Company | Emerson, Herrmann, Dukane, Sonics & Materials, Sonic Italia, Seidensha Electronics, KSONIC, Kormax System, Xin Dongli, Nippon Avionics, Ever Ultrasonic, Hornwell, Sonobond Ultrasonics |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |