What is Tightness Detectors - Global Market?

Tightness detectors are essential tools in various industries, designed to identify and measure the tightness or integrity of seals, joints, and enclosures. These devices are crucial in ensuring that products and systems are leak-proof, which is vital for maintaining safety, efficiency, and quality. The global market for tightness detectors is experiencing significant growth due to increasing demand across multiple sectors, including automotive, aerospace, manufacturing, and construction. As industries continue to prioritize safety and quality assurance, the need for reliable tightness detection solutions becomes more pronounced. These detectors employ various technologies, such as ultrasonic, pressure decay, and helium leak detection, to provide accurate and reliable results. The market's expansion is also driven by advancements in technology, which have led to the development of more sophisticated and user-friendly devices. Additionally, stringent regulations and standards across industries further propel the demand for tightness detectors, as companies strive to comply with safety and environmental guidelines. Overall, the global market for tightness detectors is poised for continued growth, driven by technological advancements, regulatory requirements, and the increasing emphasis on safety and quality assurance across industries.

Hammering Method, Ultrasound in the Tightness Detectors - Global Market:

The hammering method and ultrasound-based techniques are two prominent approaches used in tightness detectors within the global market. The hammering method is a traditional technique that involves striking a surface with a hammer or similar tool to detect any changes in sound or vibration that may indicate a lack of tightness or the presence of a leak. This method is often used in industries where quick and cost-effective solutions are needed, such as construction and manufacturing. It is particularly useful for detecting large leaks or structural weaknesses, as the sound produced by the hammering can reveal inconsistencies in the material. However, the hammering method has its limitations, as it may not be as precise or effective in detecting smaller leaks or in complex systems where access to certain areas is restricted. On the other hand, ultrasound-based techniques offer a more advanced and precise approach to tightness detection. These methods utilize high-frequency sound waves to detect leaks or weaknesses in seals and joints. Ultrasound detectors are highly sensitive and can identify even the smallest leaks, making them ideal for industries where precision is crucial, such as aerospace, automotive, and medical devices. The technology works by emitting ultrasonic waves that penetrate materials and reflect back to the detector, allowing it to identify any disruptions or changes in the material's integrity. This method is non-invasive and can be used on a wide range of materials, including metals, plastics, and composites. Additionally, ultrasound-based detectors are often portable and easy to use, making them a popular choice for field inspections and maintenance. The global market for tightness detectors is increasingly adopting ultrasound-based techniques due to their accuracy, reliability, and versatility. These detectors are particularly valuable in industries where safety and quality are paramount, as they provide a non-destructive means of ensuring the integrity of critical components and systems. Furthermore, advancements in ultrasound technology have led to the development of more sophisticated detectors that offer enhanced features, such as digital displays, data logging, and wireless connectivity. These innovations have made ultrasound-based tightness detectors more accessible and user-friendly, further driving their adoption across various sectors. In summary, both the hammering method and ultrasound-based techniques play significant roles in the global market for tightness detectors. While the hammering method offers a simple and cost-effective solution for detecting large leaks and structural weaknesses, ultrasound-based techniques provide a more precise and reliable means of ensuring the integrity of seals and joints. As industries continue to prioritize safety and quality assurance, the demand for advanced tightness detection solutions is expected to grow, with ultrasound-based detectors leading the way due to their accuracy, versatility, and ease of use.

Medical, Industry, Food, Others in the Tightness Detectors - Global Market:

Tightness detectors play a crucial role in various sectors, including medical, industrial, food, and other applications, by ensuring the integrity and safety of products and systems. In the medical field, tightness detectors are essential for maintaining the sterility and functionality of medical devices and equipment. They are used to test the seals of packaging for sterile medical supplies, ensuring that no contaminants can enter and compromise the safety of the products. Additionally, tightness detectors are employed in the manufacturing of medical devices, such as syringes, catheters, and implants, to ensure that they are free from leaks and defects that could pose risks to patients. In the industrial sector, tightness detectors are widely used to ensure the safety and efficiency of machinery and equipment. They are employed in the maintenance and inspection of pipelines, tanks, and pressure vessels to detect leaks that could lead to hazardous situations or costly downtime. Tightness detectors are also used in the automotive and aerospace industries to test the integrity of components such as fuel systems, air conditioning units, and hydraulic systems, where even minor leaks can have significant consequences. The food industry relies on tightness detectors to ensure the safety and quality of packaged goods. These devices are used to test the seals of food packaging, such as cans, bottles, and vacuum-sealed bags, to prevent contamination and spoilage. By ensuring that packaging is airtight, tightness detectors help maintain the freshness and shelf life of food products, which is crucial for consumer safety and satisfaction. Beyond these specific sectors, tightness detectors find applications in various other areas, such as construction, electronics, and environmental monitoring. In construction, they are used to test the integrity of building envelopes, ensuring that structures are weatherproof and energy-efficient. In electronics, tightness detectors help ensure the reliability of components by detecting leaks in enclosures that could lead to moisture ingress and damage. In environmental monitoring, these devices are used to detect leaks in containment systems for hazardous materials, helping to prevent environmental contamination. Overall, the global market for tightness detectors is driven by their diverse applications across multiple sectors. As industries continue to prioritize safety, quality, and efficiency, the demand for reliable tightness detection solutions is expected to grow. These devices play a vital role in ensuring the integrity of products and systems, contributing to the overall safety and well-being of consumers and the environment.

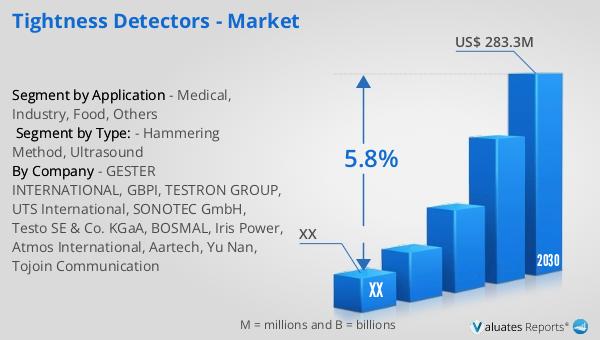

Tightness Detectors - Global Market Outlook:

The global market for tightness detectors was valued at approximately $191.2 million in 2023, with projections indicating a growth to around $283.3 million by 2030. This represents a compound annual growth rate (CAGR) of 5.8% during the forecast period from 2024 to 2030. This growth is indicative of the increasing demand for tightness detectors across various industries, driven by the need for enhanced safety, quality assurance, and compliance with regulatory standards. The market's expansion is further supported by technological advancements that have led to the development of more sophisticated and user-friendly devices. In comparison, the global market for medical devices was estimated at $603 billion in 2023, with a projected CAGR of 5% over the next six years. This highlights the significant growth potential of the tightness detectors market, as industries continue to prioritize safety and quality assurance. The increasing adoption of tightness detectors in sectors such as automotive, aerospace, manufacturing, and construction is expected to drive market growth, as companies strive to ensure the integrity and reliability of their products and systems. Overall, the global market for tightness detectors is poised for continued expansion, driven by technological advancements, regulatory requirements, and the growing emphasis on safety and quality across industries.

| Report Metric | Details |

| Report Name | Tightness Detectors - Market |

| Forecasted market size in 2030 | US$ 283.3 million |

| CAGR | 5.8% |

| Forecasted years | 2024 - 2030 |

| Segment by Type: |

|

| Segment by Application |

|

| By Region |

|

| By Company | GESTER INTERNATIONAL, GBPI, TESTRON GROUP, UTS International, SONOTEC GmbH, Testo SE & Co. KGaA, BOSMAL, Iris Power, Atmos International, Aartech, Yu Nan, Tojoin Communication |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |