What is PVD Coating Machinery - Global Market?

Physical Vapor Deposition (PVD) Coating Machinery is a sophisticated technology used in various industries to apply thin films onto surfaces. This process involves the transition of material from a condensed phase to a vapor phase and then back to a thin film condensed phase. PVD coating is renowned for its ability to enhance the durability, appearance, and performance of products by providing a hard, wear-resistant surface. The global market for PVD coating machinery is expanding due to its applications in sectors such as electronics, automotive, and tools. The machinery used in PVD coating includes evaporation equipment, sputtering equipment, and other specialized tools that facilitate the deposition of thin films. The demand for PVD coating machinery is driven by the need for advanced coatings that offer superior protection and aesthetic appeal, making it a crucial component in modern manufacturing processes. As industries continue to seek innovative solutions for surface treatment, the PVD coating machinery market is poised for significant growth, offering opportunities for manufacturers and end-users alike.

Evaporation Equipment, Sputtering Equipment, Others in the PVD Coating Machinery - Global Market:

Evaporation equipment, sputtering equipment, and other types of machinery play pivotal roles in the PVD coating process, each offering unique advantages and applications. Evaporation equipment is a fundamental component of PVD coating machinery, utilizing thermal energy to vaporize the coating material, which then condenses onto the substrate to form a thin film. This method is particularly effective for applying coatings that require high purity and uniformity, making it ideal for applications in the electronics and optics industries. The process is relatively straightforward, involving the heating of the coating material in a vacuum chamber until it evaporates and subsequently deposits onto the target surface. This technique is favored for its ability to produce high-quality coatings with excellent adhesion and minimal defects.

Electronics and Panel Display, Optics and Glass, Automotive, Tools and Hardware, Other in the PVD Coating Machinery - Global Market:

Sputtering equipment, on the other hand, employs a different mechanism to achieve thin film deposition. In this process, ions are accelerated towards a target material, causing atoms to be ejected and deposited onto the substrate. Sputtering is highly versatile and can be used to deposit a wide range of materials, including metals, alloys, and compounds. It is particularly advantageous for creating coatings with complex compositions and structures, as well as for depositing materials that are difficult to evaporate. The precision and control offered by sputtering equipment make it a preferred choice for applications in the semiconductor and optical industries, where intricate and high-performance coatings are required.

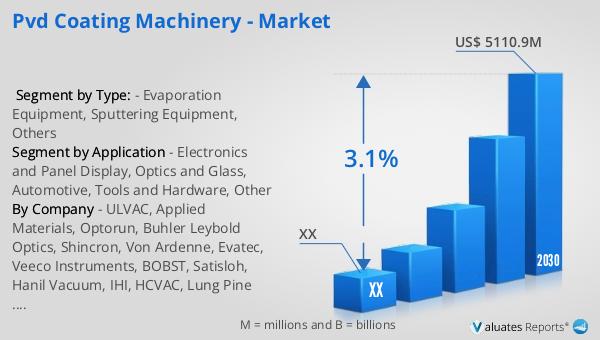

PVD Coating Machinery - Global Market Outlook:

In addition to evaporation and sputtering equipment, the PVD coating machinery market also includes other specialized tools and technologies that cater to specific coating requirements. These may include arc deposition systems, ion plating equipment, and hybrid systems that combine multiple deposition techniques. Each of these technologies offers distinct benefits, such as enhanced coating adhesion, improved surface hardness, and the ability to deposit coatings on complex geometries. The choice of equipment depends on factors such as the desired coating properties, substrate material, and application requirements. As the demand for advanced coatings continues to grow, manufacturers are investing in research and development to enhance the capabilities of PVD coating machinery, ensuring that it meets the evolving needs of various industries.

| Report Metric | Details |

| Report Name | PVD Coating Machinery - Market |

| Forecasted market size in 2030 | US$ 5110.9 million |

| CAGR | 3.1% |

| Forecasted years | 2024 - 2030 |

| Segment by Type: |

|

| Segment by Application |

|

| By Region |

|

| By Company | ULVAC, Applied Materials, Optorun, Buhler Leybold Optics, Shincron, Von Ardenne, Evatec, Veeco Instruments, BOBST, Satisloh, Hanil Vacuum, IHI, HCVAC, Lung Pine Vacuum, Hongda Vacuum, Platit, Beijing Power Tech, SKY Technology, Impact Coatings, Denton Vacuum, ZHEN HUA, Mustang Vacuum Systems, KYZK |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |