What is Push-through-package Aluminum Foil for Pharmaceuticals - Global Market?

Push-through-package aluminum foil is a specialized packaging material used extensively in the pharmaceutical industry. This type of packaging is designed to protect medications from environmental factors such as moisture, light, and oxygen, which can degrade the quality and efficacy of the drugs. The global market for push-through-package aluminum foil is driven by the increasing demand for safe and secure pharmaceutical packaging solutions. As the pharmaceutical industry continues to grow, particularly in emerging markets, the need for reliable packaging materials that ensure the integrity of medications is becoming more critical. Push-through-package aluminum foil offers a robust barrier against contamination and tampering, making it an ideal choice for packaging sensitive pharmaceutical products. Its versatility allows it to be used for various forms of medication, including tablets, capsules, and suppositories. The global market for this packaging solution is expected to expand as pharmaceutical companies seek to comply with stringent regulatory requirements and enhance the safety of their products. The durability and protective qualities of push-through-package aluminum foil make it a valuable component in the pharmaceutical supply chain, ensuring that medications reach consumers in optimal condition.

Double-sided Matched Pattern Push-through-package Aluminum Foil, Push-through-package Aluminum Foil for Use with Infrared Inspection Devices, Others in the Push-through-package Aluminum Foil for Pharmaceuticals - Global Market:

Double-sided matched pattern push-through-package aluminum foil is a specialized variant of aluminum foil used in pharmaceutical packaging. This type of foil features a unique design with patterns on both sides, which enhances its protective capabilities. The double-sided pattern provides an additional layer of security, making it more difficult for counterfeiters to replicate the packaging. This is particularly important in the pharmaceutical industry, where the authenticity of medications is crucial for patient safety. The global market for double-sided matched pattern push-through-package aluminum foil is driven by the increasing need for secure packaging solutions that can prevent tampering and ensure the integrity of pharmaceutical products. As regulatory bodies around the world continue to tighten their standards for pharmaceutical packaging, the demand for innovative solutions like double-sided matched pattern foil is expected to grow. This type of foil is particularly useful for packaging high-value medications that require an extra level of protection against counterfeiting and tampering. In addition to its security benefits, double-sided matched pattern foil also offers excellent barrier properties, protecting medications from moisture, light, and oxygen. This helps to preserve the quality and efficacy of the drugs, ensuring that they remain safe and effective for patients. Push-through-package aluminum foil for use with infrared inspection devices is another important segment of the global market. This type of foil is designed to be compatible with infrared inspection technology, which is used to verify the integrity of pharmaceutical packaging. Infrared inspection devices can detect defects in the packaging, such as pinholes or cracks, that may compromise the safety of the medications. By using push-through-package aluminum foil that is compatible with infrared inspection, pharmaceutical companies can ensure that their products meet the highest standards of quality and safety. This is particularly important for medications that are sensitive to environmental factors, as even minor defects in the packaging can lead to degradation of the drugs. The global market for push-through-package aluminum foil for use with infrared inspection devices is expected to grow as pharmaceutical companies increasingly adopt advanced inspection technologies to enhance the safety and quality of their products. Other types of push-through-package aluminum foil used in the pharmaceutical industry include those with specialized coatings or laminates that provide additional protection against environmental factors. These coatings can enhance the barrier properties of the foil, making it even more effective at protecting medications from moisture, light, and oxygen. The global market for these specialized types of push-through-package aluminum foil is driven by the increasing demand for high-performance packaging solutions that can ensure the safety and efficacy of pharmaceutical products. As the pharmaceutical industry continues to evolve, the need for innovative packaging materials that can meet the challenges of modern drug development and distribution is becoming more critical. Push-through-package aluminum foil, with its versatility and protective qualities, is well-positioned to meet these demands and play a key role in the future of pharmaceutical packaging.

Capsule Package, Suppository Package, Tablets Package in the Push-through-package Aluminum Foil for Pharmaceuticals - Global Market:

Push-through-package aluminum foil is widely used in the pharmaceutical industry for packaging various forms of medication, including capsules, suppositories, and tablets. Each of these applications requires specific packaging solutions to ensure the safety and efficacy of the medications. For capsule packaging, push-through-package aluminum foil provides a robust barrier against moisture, light, and oxygen, which can degrade the quality of the capsules. Capsules are often sensitive to environmental factors, and exposure to moisture or light can cause them to become brittle or discolored. By using push-through-package aluminum foil, pharmaceutical companies can protect capsules from these harmful elements, ensuring that they remain safe and effective for patients. The foil's push-through design also makes it easy for patients to access their medication, providing a convenient and user-friendly packaging solution. In the case of suppository packaging, push-through-package aluminum foil offers similar protective benefits. Suppositories are particularly sensitive to temperature changes and can easily melt or deform if not properly protected. The aluminum foil provides an excellent barrier against temperature fluctuations, helping to maintain the integrity of the suppositories during storage and transportation. Additionally, the push-through design allows for easy and hygienic access to the medication, which is important for patient safety and convenience. For tablet packaging, push-through-package aluminum foil is an ideal solution due to its excellent barrier properties and ease of use. Tablets are often coated with protective layers to enhance their stability and shelf life, but they still require additional protection from environmental factors. The aluminum foil provides a strong barrier against moisture, light, and oxygen, helping to preserve the quality and efficacy of the tablets. The push-through design also makes it easy for patients to access their medication, reducing the risk of contamination and ensuring that the tablets remain safe and effective. Overall, the use of push-through-package aluminum foil in pharmaceutical packaging offers numerous benefits for both manufacturers and patients. Its protective qualities help to ensure the safety and efficacy of medications, while its user-friendly design makes it easy for patients to access their medication. As the pharmaceutical industry continues to grow and evolve, the demand for reliable and innovative packaging solutions like push-through-package aluminum foil is expected to increase. This versatile packaging material is well-suited to meet the challenges of modern drug development and distribution, providing a valuable solution for the pharmaceutical industry.

Push-through-package Aluminum Foil for Pharmaceuticals - Global Market Outlook:

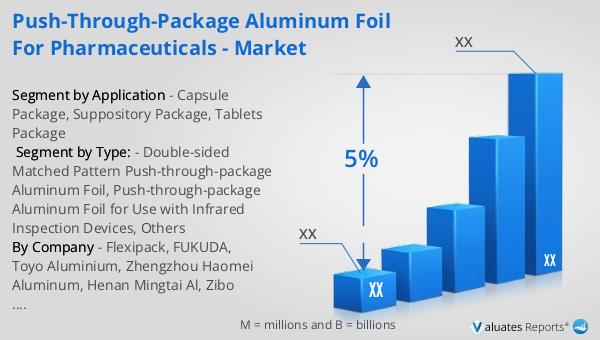

The global pharmaceutical market was valued at approximately 1,475 billion USD in 2022, and it is projected to grow at a compound annual growth rate (CAGR) of 5% over the next six years. This growth is indicative of the increasing demand for pharmaceutical products worldwide, driven by factors such as an aging population, rising prevalence of chronic diseases, and advancements in drug development. In comparison, the chemical drug market has shown a steady increase, growing from 1,005 billion USD in 2018 to an estimated 1,094 billion USD in 2022. This growth reflects the ongoing demand for chemical-based medications, which continue to play a significant role in the treatment of various health conditions. The expansion of the pharmaceutical market highlights the importance of reliable and secure packaging solutions, such as push-through-package aluminum foil, to ensure the safety and efficacy of medications. As the market continues to grow, the need for innovative packaging materials that can meet the challenges of modern drug development and distribution will become increasingly critical. Push-through-package aluminum foil, with its protective qualities and versatility, is well-positioned to meet these demands and support the growth of the pharmaceutical industry.

| Report Metric | Details |

| Report Name | Push-through-package Aluminum Foil for Pharmaceuticals - Market |

| CAGR | 5% |

| Segment by Type: |

|

| Segment by Application |

|

| By Region |

|

| By Company | Flexipack, FUKUDA, Toyo Aluminium, Zhengzhou Haomei Aluminum, Henan Mingtai Al, Zibo Horzion Foil, Henan Roshn Packaging Materials, Zhengzhou Zhuofeng Aluminum, Taixing Group, Henan Henry Metal Material, Xinmingyu New Material Technology, JEREL New Material |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |