What is PTFE Micronized Powders - Global Market?

PTFE micronized powders are a specialized form of polytetrafluoroethylene, a synthetic fluoropolymer of tetrafluoroethylene, known for its exceptional properties such as high thermal stability, chemical resistance, and low friction. These powders are finely ground particles of PTFE, typically ranging from 1 to 20 microns in size, and are used in various industrial applications due to their unique characteristics. The global market for PTFE micronized powders is driven by their increasing demand in industries such as automotive, electronics, and coatings, where they are used to enhance the performance and durability of products. These powders are particularly valued for their ability to reduce friction and wear, improve non-stick properties, and provide excellent electrical insulation. As industries continue to seek materials that offer high performance and reliability, the demand for PTFE micronized powders is expected to grow, making them a crucial component in the development of advanced materials and technologies.

Monomer Polymerization, Resin Degradation in the PTFE Micronized Powders - Global Market:

Monomer polymerization and resin degradation are two critical processes in the production and application of PTFE micronized powders. Monomer polymerization refers to the chemical reaction where monomers, the basic building blocks of polymers, are chemically bonded to form a polymer chain. In the case of PTFE, the monomer tetrafluoroethylene undergoes polymerization to form the PTFE polymer. This process is typically carried out under high pressure and temperature conditions, often in the presence of a catalyst, to initiate the polymerization reaction. The resulting PTFE polymer is then processed into various forms, including micronized powders, through techniques such as grinding or milling. These powders retain the inherent properties of PTFE, such as high thermal stability and chemical resistance, making them suitable for a wide range of applications. On the other hand, resin degradation refers to the breakdown of the polymer structure, which can occur due to various factors such as heat, chemical exposure, or mechanical stress. In the context of PTFE micronized powders, resin degradation is a critical consideration as it can affect the performance and longevity of the material. For instance, exposure to high temperatures or aggressive chemicals can lead to the breakdown of the PTFE polymer chains, resulting in a loss of mechanical strength and chemical resistance. To mitigate the effects of resin degradation, manufacturers often incorporate stabilizers or additives into the PTFE formulation to enhance its resistance to thermal and chemical degradation. Additionally, the processing conditions, such as temperature and pressure, are carefully controlled to minimize the risk of degradation during the production of PTFE micronized powders. Understanding the mechanisms of monomer polymerization and resin degradation is essential for optimizing the production and application of PTFE micronized powders. By controlling these processes, manufacturers can produce high-quality PTFE powders with consistent properties, ensuring their suitability for demanding applications in industries such as automotive, electronics, and coatings. Furthermore, advancements in polymerization techniques and the development of new additives continue to enhance the performance and durability of PTFE micronized powders, expanding their potential applications and driving their demand in the global market.

Ink, Thermoplastic, Coating, Lubricants & Grease, Additives, Others in the PTFE Micronized Powders - Global Market:

PTFE micronized powders find extensive usage across various industries due to their unique properties. In the ink industry, these powders are used to enhance the performance of printing inks by improving their flow and reducing friction. The addition of PTFE micronized powders to inks results in smoother printing, reduced wear on printing equipment, and improved print quality. In the thermoplastic industry, PTFE micronized powders are used as additives to improve the wear resistance and lubricity of thermoplastic materials. This is particularly beneficial in applications where low friction and high durability are required, such as in automotive components and industrial machinery. In the coatings industry, PTFE micronized powders are used to create non-stick and anti-corrosion coatings. These powders provide excellent chemical resistance and thermal stability, making them ideal for use in harsh environments. They are commonly used in cookware, industrial equipment, and architectural applications to enhance the durability and performance of coatings. In the lubricants and grease industry, PTFE micronized powders are used to improve the lubricity and wear resistance of lubricants. The addition of these powders reduces friction and wear, extending the life of mechanical components and improving their efficiency. PTFE micronized powders are also used as additives in various other applications, such as in the production of gaskets, seals, and bearings, where their low friction and high chemical resistance are highly valued. Overall, the versatility and unique properties of PTFE micronized powders make them an essential component in a wide range of industrial applications, driving their demand in the global market.

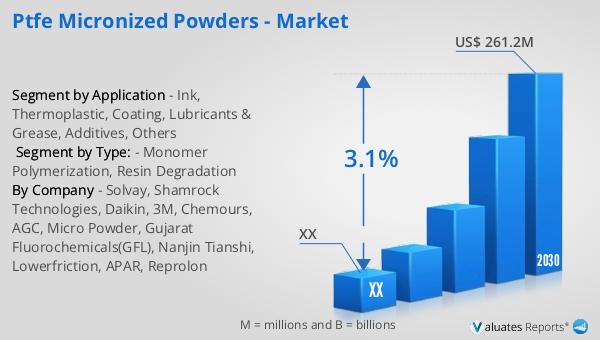

PTFE Micronized Powders - Global Market Outlook:

The global market for PTFE micronized powders was valued at approximately US$ 210 million in 2023, with projections indicating a growth to US$ 261.2 million by 2030. This growth is expected to occur at a compound annual growth rate (CAGR) of 3.1% during the forecast period from 2024 to 2030. Key players in the global PTFE micronized powder market include companies such as Sanye Technology, Daikin Fluorochemicals, and Chemours, among others. These top three manufacturers collectively hold a market share of over 30%, highlighting their significant influence in the industry. The market's growth is driven by the increasing demand for high-performance materials in various industries, including automotive, electronics, and coatings. PTFE micronized powders are valued for their exceptional properties, such as high thermal stability, chemical resistance, and low friction, which make them suitable for a wide range of applications. As industries continue to seek materials that offer enhanced performance and durability, the demand for PTFE micronized powders is expected to grow, driving the market's expansion. The competitive landscape of the PTFE micronized powder market is characterized by the presence of several key players, each striving to enhance their product offerings and expand their market presence. These companies are investing in research and development to develop new and innovative products that meet the evolving needs of their customers. Additionally, strategic partnerships and collaborations are being pursued to strengthen their market position and expand their customer base. Overall, the global market for PTFE micronized powders is poised for steady growth, driven by the increasing demand for high-performance materials and the continuous efforts of key players to innovate and expand their market presence.

| Report Metric | Details |

| Report Name | PTFE Micronized Powders - Market |

| Forecasted market size in 2030 | US$ 261.2 million |

| CAGR | 3.1% |

| Forecasted years | 2024 - 2030 |

| Segment by Type: |

|

| Segment by Application |

|

| By Region |

|

| By Company | Solvay, Shamrock Technologies, Daikin, 3M, Chemours, AGC, Micro Powder, Gujarat Fluorochemicals(GFL), Nanjin Tianshi, Lowerfriction, APAR, Reprolon |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |