What is Portable Milling Machine - Global Market?

A portable milling machine is a versatile tool used in various industries for on-site machining tasks. Unlike traditional milling machines that are stationary, portable milling machines are designed to be easily transported and set up in different locations. This flexibility allows them to perform milling operations directly on large structures or components that cannot be easily moved. The global market for portable milling machines is driven by the need for efficient and precise machining solutions in industries such as construction, shipbuilding, and aerospace. These machines are equipped with advanced features that enable them to handle complex milling tasks with high accuracy. They are used for tasks such as facing, slotting, and cutting, providing a cost-effective solution for maintenance and repair operations. The demand for portable milling machines is expected to grow as industries continue to seek innovative solutions for on-site machining challenges. Their ability to reduce downtime and improve productivity makes them an essential tool in modern manufacturing and maintenance processes. As technology advances, portable milling machines are likely to incorporate more smart features, enhancing their capabilities and expanding their applications across various sectors.

Portable Two-axis Gantry Milling Machine, Portable Three-axis Gantry Milling Machine, Portable Three-axis Linear Milling Machine, Others in the Portable Milling Machine - Global Market:

Portable milling machines come in various configurations, each designed to meet specific machining needs. The portable two-axis gantry milling machine is a compact and efficient tool used for milling operations that require movement along two axes. This type of machine is ideal for tasks that involve flat surfaces or simple geometries. It is commonly used in industries where space is limited, and precision is crucial. The portable three-axis gantry milling machine, on the other hand, offers an additional axis of movement, allowing for more complex milling operations. This machine is suitable for tasks that require intricate detailing and precision, making it a popular choice in industries such as aerospace and automotive manufacturing. The portable three-axis linear milling machine is designed for linear milling tasks, providing high accuracy and efficiency. It is often used in applications where long, straight cuts are required, such as in the construction of large structures or components. Other types of portable milling machines include those with specialized features or configurations, designed to meet specific industry requirements. These machines are equipped with advanced technology that allows them to perform a wide range of milling operations with precision and efficiency. As the demand for portable milling machines continues to grow, manufacturers are focusing on developing innovative solutions that cater to the diverse needs of different industries. This includes the integration of smart features such as real-time monitoring, data collection, and remote control capabilities, which enhance the functionality and versatility of these machines. The global market for portable milling machines is expected to expand as industries continue to seek efficient and cost-effective solutions for on-site machining tasks. The ability of these machines to perform complex milling operations with high precision makes them an invaluable tool in modern manufacturing and maintenance processes. As technology continues to evolve, portable milling machines are likely to become even more advanced, offering new possibilities for on-site machining applications across various sectors.

Aerospace, Shipbuilding, Others in the Portable Milling Machine - Global Market:

Portable milling machines are widely used in the aerospace industry for their ability to perform precise and complex machining tasks on-site. In aerospace manufacturing and maintenance, the need for high precision and accuracy is paramount. Portable milling machines allow for the machining of large aircraft components without the need to disassemble them, reducing downtime and improving efficiency. These machines are used for tasks such as milling, drilling, and cutting, providing a cost-effective solution for maintenance and repair operations. In the shipbuilding industry, portable milling machines are used for on-site machining of large ship components. The ability to perform milling operations directly on the ship reduces the need for transporting large components to a separate machining facility, saving time and resources. Portable milling machines are used for tasks such as facing, slotting, and cutting, providing a versatile solution for shipbuilding and maintenance operations. Other industries that benefit from the use of portable milling machines include construction, energy, and manufacturing. In construction, these machines are used for on-site machining of large structures, such as bridges and buildings, providing a cost-effective solution for maintenance and repair operations. In the energy sector, portable milling machines are used for machining tasks in power plants and refineries, where precision and efficiency are crucial. The versatility and efficiency of portable milling machines make them an essential tool in various industries, providing a cost-effective solution for on-site machining tasks. As technology continues to advance, these machines are likely to incorporate more smart features, enhancing their capabilities and expanding their applications across different sectors.

Portable Milling Machine - Global Market Outlook:

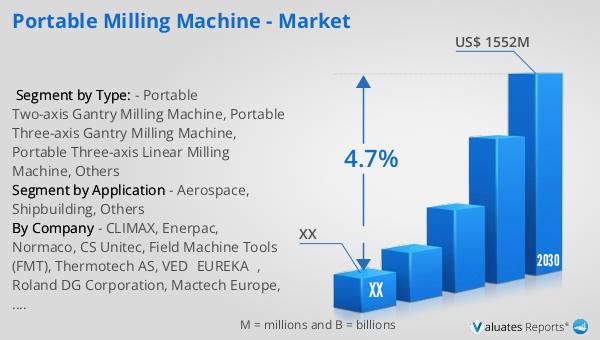

The global market for portable milling machines was valued at approximately $9,891.4 million in 2023. It is projected to reach a revised size of $1,552 million by 2030, growing at a compound annual growth rate (CAGR) of 4.7% from 2024 to 2030. This growth reflects the increasing demand for efficient and precise on-site machining solutions across various industries. As with many industrial machines, portable milling machines are expected to integrate smart features such as real-time monitoring, data collection, and remote control capabilities. These advancements will enhance the functionality and versatility of portable milling machines, making them even more valuable in modern manufacturing and maintenance processes. The integration of smart features will allow for improved efficiency and productivity, reducing downtime and increasing the overall effectiveness of on-site machining operations. As industries continue to seek innovative solutions for their machining needs, the demand for portable milling machines is expected to grow, driving the market forward. The ability of these machines to perform complex milling operations with high precision makes them an essential tool in various sectors, providing a cost-effective solution for on-site machining tasks. As technology continues to evolve, portable milling machines are likely to become even more advanced, offering new possibilities for on-site machining applications across different industries.

| Report Metric | Details |

| Report Name | Portable Milling Machine - Market |

| Forecasted market size in 2030 | US$ 1552 million |

| CAGR | 4.7% |

| Forecasted years | 2024 - 2030 |

| Segment by Type: |

|

| Segment by Application |

|

| By Region |

|

| By Company | CLIMAX, Enerpac, Normaco, CS Unitec, Field Machine Tools (FMT), Thermotech AS, VED(EUREKA), Roland DG Corporation, Mactech Europe, Dongguan Portable Tools Co., Ltd. |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |