What is Plastic Breather Valve - Global Market?

Plastic breather valves are essential components in various industries, designed to maintain optimal pressure levels within containers and systems. These valves allow air to enter or exit a system, preventing pressure build-up that could lead to equipment failure or safety hazards. The global market for plastic breather valves is driven by their widespread application across numerous sectors, including automotive, chemical, and manufacturing industries. These valves are typically made from durable plastic materials that can withstand harsh environmental conditions, making them suitable for use in both indoor and outdoor settings. The demand for plastic breather valves is increasing as industries continue to prioritize safety and efficiency in their operations. Additionally, advancements in technology have led to the development of more sophisticated breather valves that offer enhanced performance and reliability. As a result, the global market for plastic breather valves is expected to experience steady growth in the coming years, driven by the need for effective pressure management solutions across various industries.

Manual Type, Electric Type in the Plastic Breather Valve - Global Market:

Plastic breather valves come in two main types: manual and electric. Manual plastic breather valves are operated by hand, requiring human intervention to open or close the valve. These valves are typically used in applications where precise control over pressure levels is not critical, or where automation is not feasible. Manual valves are often more cost-effective than their electric counterparts, making them a popular choice for smaller operations or those with limited budgets. They are also relatively easy to install and maintain, requiring minimal technical expertise. However, manual valves may not be suitable for applications that require frequent adjustments or where rapid response to pressure changes is necessary. On the other hand, electric plastic breather valves are designed for automated operation, using electrical signals to control the opening and closing of the valve. These valves are ideal for applications that require precise pressure control or where automation can enhance efficiency and safety. Electric valves can be integrated into larger control systems, allowing for remote monitoring and adjustment of pressure levels. This makes them particularly useful in industries such as chemical processing or manufacturing, where maintaining consistent pressure is crucial to the quality and safety of the final product. While electric valves tend to be more expensive than manual ones, their ability to improve operational efficiency and reduce the risk of human error can justify the higher initial investment. Additionally, advancements in technology have led to the development of more sophisticated electric valves that offer enhanced performance and reliability. These valves often come with features such as programmable settings, real-time monitoring, and diagnostic capabilities, making them a valuable asset in modern industrial operations. Despite their higher cost, the benefits of electric plastic breather valves in terms of efficiency, safety, and precision make them an attractive option for many industries. As technology continues to advance, it is likely that the demand for electric breather valves will continue to grow, driven by the need for more efficient and reliable pressure management solutions.

Petroleum, Chemical Industry, Smelt, Others in the Plastic Breather Valve - Global Market:

Plastic breather valves play a crucial role in various industries, including petroleum, chemical, smelting, and others, by ensuring safe and efficient operations. In the petroleum industry, these valves are used to manage pressure levels in storage tanks and pipelines, preventing the build-up of pressure that could lead to leaks or explosions. The ability to maintain optimal pressure levels is essential in this industry, where safety and environmental concerns are paramount. Plastic breather valves are favored for their durability and resistance to harsh chemicals, making them suitable for use in the challenging conditions often encountered in the petroleum sector. In the chemical industry, plastic breather valves are used to regulate pressure in reactors and storage vessels, ensuring that chemical reactions occur under controlled conditions. This is critical for maintaining product quality and preventing accidents that could result from uncontrolled pressure changes. The use of plastic materials in these valves provides resistance to corrosion and chemical degradation, ensuring long-term reliability and performance. In the smelting industry, plastic breather valves are used to manage pressure in furnaces and other equipment, preventing damage and ensuring efficient operation. The ability to withstand high temperatures and corrosive environments makes plastic breather valves an ideal choice for this industry. Additionally, these valves help to reduce energy consumption by maintaining optimal pressure levels, contributing to more sustainable operations. Beyond these specific industries, plastic breather valves are also used in a variety of other applications, including water treatment, food and beverage processing, and pharmaceuticals. In each of these areas, the ability to maintain consistent pressure levels is critical to ensuring product quality and safety. The versatility and durability of plastic breather valves make them a valuable tool in a wide range of industrial applications, driving demand in the global market.

Plastic Breather Valve - Global Market Outlook:

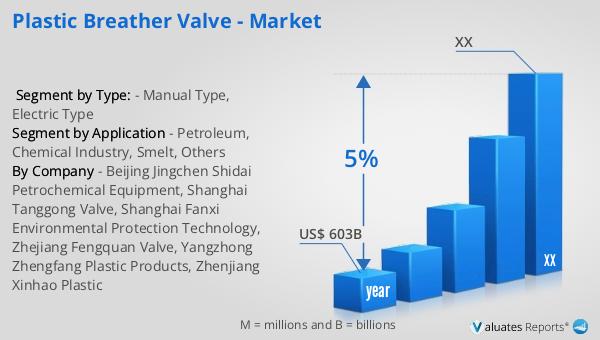

Our research indicates that the global market for medical devices is projected to reach approximately USD 603 billion in 2023, with an anticipated growth rate of 5% annually over the next six years. This growth is driven by several factors, including advancements in medical technology, an aging global population, and increasing demand for healthcare services. As medical devices become more sophisticated and capable of addressing a wider range of health issues, their adoption is expected to rise, contributing to market expansion. Additionally, the growing prevalence of chronic diseases and the need for effective diagnostic and treatment solutions are further fueling demand for medical devices. The market's steady growth is also supported by increasing healthcare expenditure and government initiatives aimed at improving healthcare infrastructure. As a result, the medical device industry is poised for significant growth, offering numerous opportunities for innovation and investment. Companies operating in this sector are likely to benefit from the expanding market, provided they can adapt to changing regulatory requirements and technological advancements. Overall, the global medical device market presents a promising outlook, with sustained growth expected in the coming years.

| Report Metric | Details |

| Report Name | Plastic Breather Valve - Market |

| Accounted market size in year | US$ 603 billion |

| CAGR | 5% |

| Base Year | year |

| Segment by Type: |

|

| Segment by Application |

|

| By Region |

|

| By Company | Beijing Jingchen Shidai Petrochemical Equipment, Shanghai Tanggong Valve, Shanghai Fanxi Environmental Protection Technology, Zhejiang Fengquan Valve, Yangzhong Zhengfang Plastic Products, Zhenjiang Xinhao Plastic |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |