What is Photocurable Resin Coatings - Global Market?

Photocurable resin coatings represent a significant segment within the global coatings market, characterized by their unique ability to cure or harden upon exposure to light, typically ultraviolet (UV) or visible light. These coatings are formulated using a combination of monomers, oligomers, and photoinitiators, which together create a system that rapidly transitions from a liquid to a solid state when exposed to light. This rapid curing process offers several advantages, including reduced energy consumption, lower emissions of volatile organic compounds (VOCs), and enhanced performance characteristics such as improved durability, chemical resistance, and aesthetic appeal. The global market for photocurable resin coatings is driven by increasing demand across various industries, including electronics, automotive, and graphic arts, where the need for high-performance, environmentally friendly coatings is paramount. As industries continue to seek sustainable and efficient solutions, the adoption of photocurable resin coatings is expected to grow, supported by ongoing advancements in photoinitiator technology and the development of new formulations that enhance the properties and applications of these coatings. The market's growth is further bolstered by the rising trend of digitalization and automation in manufacturing processes, which aligns well with the fast-curing nature of photocurable coatings.

Monomers, Oligomers, Photoinitiaters in the Photocurable Resin Coatings - Global Market:

Monomers, oligomers, and photoinitiators are the fundamental components of photocurable resin coatings, each playing a crucial role in the formulation and performance of these coatings. Monomers are small, reactive molecules that serve as the building blocks of the polymer network formed during the curing process. They are responsible for the initial viscosity and flow characteristics of the coating, as well as its final mechanical properties. Common monomers used in photocurable coatings include acrylates and methacrylates, which are chosen for their ability to rapidly polymerize under UV light, forming a hard, durable film. Oligomers, on the other hand, are larger, pre-polymerized molecules that provide the backbone of the coating. They determine the coating's flexibility, adhesion, and chemical resistance, and are typically selected based on the specific performance requirements of the application. Epoxy acrylates, urethane acrylates, and polyester acrylates are among the most commonly used oligomers in photocurable coatings, each offering a unique balance of properties that can be tailored to meet the needs of different industries. Photoinitiators are the third critical component, responsible for initiating the polymerization process when exposed to light. They absorb the energy from the light source and generate reactive species that trigger the cross-linking of monomers and oligomers, transforming the liquid coating into a solid film. The choice of photoinitiator is crucial, as it affects the speed and efficiency of the curing process, as well as the final properties of the coating. Advances in photoinitiator technology have led to the development of new compounds that offer improved performance, such as increased sensitivity to different wavelengths of light and reduced yellowing of the cured film. Together, these components create a versatile and efficient coating system that can be customized to meet the diverse needs of the global market. The interplay between monomers, oligomers, and photoinitiators allows for the fine-tuning of properties such as hardness, flexibility, adhesion, and chemical resistance, enabling the development of coatings that are not only high-performing but also environmentally friendly. As the demand for sustainable and efficient coatings continues to grow, the role of these components in the formulation of photocurable resin coatings will remain critical, driving innovation and expansion in the global market.

Graphic Arts, Electronics, Industrial Coatings, Adhesives, Composites, Others in the Photocurable Resin Coatings - Global Market:

Photocurable resin coatings find extensive application across a variety of industries, each leveraging the unique properties of these coatings to enhance product performance and sustainability. In the graphic arts industry, photocurable coatings are used to produce high-quality prints with superior gloss, color vibrancy, and durability. The rapid curing process allows for faster production speeds and reduced energy consumption, making them an attractive option for printers looking to improve efficiency and reduce environmental impact. In the electronics industry, these coatings are used to protect sensitive components from moisture, dust, and other environmental factors. Their excellent adhesion and chemical resistance make them ideal for use in printed circuit boards, displays, and other electronic devices where reliability and longevity are critical. Industrial coatings represent another significant application area, where photocurable coatings are used to provide durable, high-performance finishes for a wide range of products, from automotive parts to consumer goods. Their fast curing times and low VOC emissions make them a preferred choice for manufacturers seeking to improve production efficiency and meet stringent environmental regulations. In the adhesives sector, photocurable resin coatings are used to create strong, durable bonds between a variety of substrates, including metals, plastics, and glass. Their ability to cure quickly and form strong, flexible bonds makes them ideal for use in applications where speed and reliability are essential. Composites are another area where photocurable coatings are gaining traction, offering enhanced performance characteristics such as improved strength, durability, and resistance to environmental factors. These coatings are used in a variety of composite applications, from aerospace to automotive, where their ability to enhance the performance and longevity of composite materials is highly valued. Other applications of photocurable resin coatings include medical devices, where their biocompatibility and ability to form strong, durable bonds make them ideal for use in a variety of medical applications. As industries continue to seek sustainable and efficient solutions, the use of photocurable resin coatings is expected to grow, driven by ongoing advancements in formulation technology and the development of new applications that leverage the unique properties of these coatings.

Photocurable Resin Coatings - Global Market Outlook:

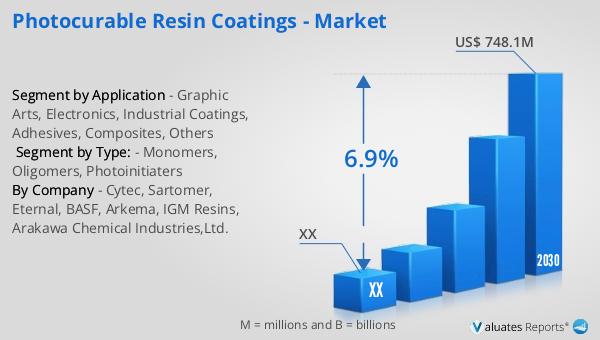

In 2023, the global market for photocurable resin coatings was valued at approximately $453.8 million. This market is projected to experience significant growth over the coming years, with expectations to reach an adjusted size of $748.1 million by 2030. This growth trajectory represents a compound annual growth rate (CAGR) of 6.9% during the forecast period from 2024 to 2030. The increasing demand for high-performance, environmentally friendly coatings across various industries is a key driver of this growth. Industries such as electronics, automotive, and graphic arts are increasingly adopting photocurable resin coatings due to their rapid curing times, reduced energy consumption, and low VOC emissions. Additionally, advancements in photoinitiator technology and the development of new formulations that enhance the properties and applications of these coatings are expected to further fuel market growth. As industries continue to seek sustainable and efficient solutions, the adoption of photocurable resin coatings is anticipated to rise, supported by the ongoing trend of digitalization and automation in manufacturing processes. This market outlook underscores the growing importance of photocurable resin coatings in the global coatings market and highlights the potential for continued innovation and expansion in this dynamic sector.

| Report Metric | Details |

| Report Name | Photocurable Resin Coatings - Market |

| Forecasted market size in 2030 | US$ 748.1 million |

| CAGR | 6.9% |

| Forecasted years | 2024 - 2030 |

| Segment by Type: |

|

| Segment by Application |

|

| By Region |

|

| By Company | Cytec, Sartomer, Eternal, BASF, Arkema, IGM Resins, Arakawa Chemical Industries,Ltd. |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |