What is Oxide Dispersion Reinforced Material - Global Market?

Oxide Dispersion Reinforced Materials (ODRMs) are advanced composite materials that incorporate fine, stable oxide particles within a metal matrix to enhance the material's mechanical properties. These materials are engineered to withstand extreme conditions, such as high temperatures and corrosive environments, making them highly valuable in various industrial applications. The global market for ODRMs is driven by the increasing demand for materials that offer superior strength, durability, and resistance to wear and tear. Industries such as aerospace, automotive, and energy are particularly interested in these materials due to their ability to maintain structural integrity under stress. The market is characterized by ongoing research and development efforts aimed at improving the performance and cost-effectiveness of these materials. As technology advances, the potential applications for ODRMs continue to expand, offering promising opportunities for growth in the global market. The integration of ODRMs into various sectors is expected to enhance product performance and longevity, thereby driving further interest and investment in this innovative material technology.

lron-based, Aluminum-based, Others in the Oxide Dispersion Reinforced Material - Global Market:

Iron-based oxide dispersion reinforced materials are among the most widely used in the global market due to their excellent mechanical properties and cost-effectiveness. These materials are typically composed of an iron matrix with finely dispersed oxide particles, such as yttria or alumina, which enhance the material's strength and resistance to high temperatures. The iron-based variants are particularly favored in industries where high thermal stability and mechanical strength are crucial, such as in the manufacturing of components for power generation and automotive applications. The ability of these materials to withstand harsh operating conditions makes them ideal for use in environments where traditional materials might fail. Aluminum-based oxide dispersion reinforced materials, on the other hand, offer a unique combination of lightweight properties and high strength. These materials are particularly valuable in industries where weight reduction is a critical factor, such as aerospace and transportation. The incorporation of oxide particles into the aluminum matrix significantly enhances its mechanical properties, allowing for the production of components that are both strong and lightweight. This makes aluminum-based ODRMs an attractive option for applications where performance and efficiency are paramount. Other types of oxide dispersion reinforced materials include those based on nickel, titanium, and other metals. These materials are often used in specialized applications where specific properties, such as corrosion resistance or high-temperature stability, are required. The versatility of ODRMs allows for their use in a wide range of industries, each with its own unique set of requirements and challenges. As the global market for these materials continues to grow, manufacturers are increasingly focusing on developing new formulations and processing techniques to meet the evolving needs of their customers. The ongoing advancements in material science and engineering are expected to drive further innovation in the field of oxide dispersion reinforced materials, opening up new possibilities for their application across various sectors.

Aerospace, Marine, Chemical in the Oxide Dispersion Reinforced Material - Global Market:

In the aerospace industry, oxide dispersion reinforced materials are highly valued for their ability to withstand extreme temperatures and mechanical stress. These materials are used in the production of critical components such as turbine blades, engine parts, and structural elements of aircraft. The high strength-to-weight ratio of ODRMs makes them ideal for aerospace applications, where reducing weight without compromising performance is a key objective. The use of these materials in aerospace not only enhances the performance and efficiency of aircraft but also contributes to fuel savings and reduced emissions. In the marine industry, oxide dispersion reinforced materials are used to manufacture components that are exposed to harsh marine environments, such as propellers, shafts, and hulls. The corrosion resistance and durability of these materials make them well-suited for use in saltwater conditions, where traditional materials might degrade over time. By incorporating ODRMs into marine applications, manufacturers can extend the lifespan of their products and reduce maintenance costs. In the chemical industry, oxide dispersion reinforced materials are used in the construction of equipment and components that must withstand corrosive substances and high temperatures. These materials are often used in the production of reactors, heat exchangers, and piping systems, where their resistance to chemical attack and thermal stability are critical. The use of ODRMs in chemical processing not only enhances the safety and reliability of equipment but also improves operational efficiency by reducing downtime and maintenance requirements. The versatility and performance benefits of oxide dispersion reinforced materials make them an attractive option for a wide range of industrial applications, driving their adoption across multiple sectors.

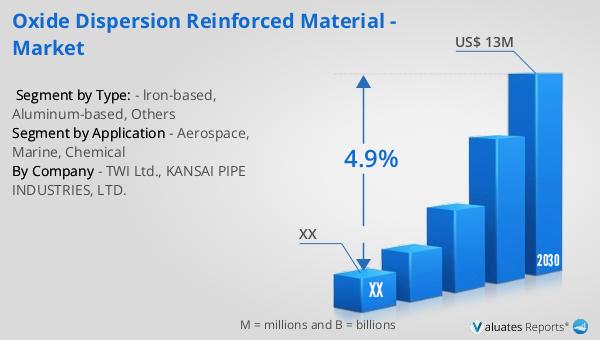

Oxide Dispersion Reinforced Material - Global Market Outlook:

The global market for Oxide Dispersion Reinforced Material was valued at approximately $9 million in 2023, with projections indicating a growth to around $13 million by 2030. This represents a compound annual growth rate (CAGR) of 4.9% during the forecast period from 2024 to 2030. The North American market, in particular, is expected to experience significant growth, although specific figures for this region were not provided. The increasing demand for advanced materials with superior mechanical properties and resistance to extreme conditions is driving the growth of the ODRM market. Industries such as aerospace, automotive, and energy are key contributors to this demand, as they seek materials that can enhance the performance and longevity of their products. The ongoing advancements in material science and engineering are expected to further fuel the growth of the ODRM market, as manufacturers continue to develop new formulations and processing techniques to meet the evolving needs of their customers. As the market expands, it is likely that we will see increased investment in research and development, as well as the emergence of new applications for these innovative materials.

| Report Metric | Details |

| Report Name | Oxide Dispersion Reinforced Material - Market |

| Forecasted market size in 2030 | US$ 13 million |

| CAGR | 4.9% |

| Forecasted years | 2024 - 2030 |

| Segment by Type: |

|

| Segment by Application |

|

| By Region |

|

| By Company | TWI Ltd., KANSAI PIPE INDUSTRIES, LTD. |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |