What is Near-infrared Optical Sorter - Global Market?

Near-infrared optical sorters are advanced machines used in various industries to separate materials based on their optical properties. These sorters utilize near-infrared (NIR) technology, which involves the use of light wavelengths just beyond the visible spectrum. This technology is particularly effective in identifying and sorting materials that may appear similar to the human eye but have different chemical compositions. The global market for near-infrared optical sorters is growing rapidly due to their efficiency and precision in sorting tasks. These machines are widely used in industries such as food processing, recycling, and mining, where they help improve product quality and reduce waste. By using NIR technology, these sorters can detect subtle differences in materials, allowing for more accurate sorting and classification. This capability is crucial in industries where purity and quality are paramount. As a result, the demand for near-infrared optical sorters is expected to continue rising as more industries recognize their benefits and integrate them into their operations.

Color Sorting, Chemical Composition Sorting in the Near-infrared Optical Sorter - Global Market:

Color sorting and chemical composition sorting are two primary applications of near-infrared optical sorters in the global market. Color sorting involves the separation of materials based on their color, which is a critical factor in industries like food processing and recycling. In the food industry, for example, color sorting is used to remove defective or discolored products, ensuring that only high-quality items reach consumers. Near-infrared optical sorters excel in this task by using NIR technology to detect even the slightest variations in color, which might be missed by traditional sorting methods. This precision helps manufacturers maintain consistent product quality and meet stringent industry standards. On the other hand, chemical composition sorting is a more complex process that involves identifying and separating materials based on their chemical makeup. This application is particularly valuable in industries such as plastics recycling and mining, where different materials may have similar appearances but vastly different chemical properties. Near-infrared optical sorters can analyze the spectral signatures of materials, allowing them to distinguish between different types of plastics or minerals. This capability is essential for recycling operations, where accurate sorting can significantly enhance the efficiency of the recycling process and improve the quality of the final product. In mining, chemical composition sorting helps in the extraction of valuable minerals by separating them from less valuable or unwanted materials. The global market for near-infrared optical sorters is driven by the increasing demand for efficient and accurate sorting solutions across various industries. As companies strive to improve their operational efficiency and reduce waste, the adoption of NIR technology is becoming more widespread. The ability of near-infrared optical sorters to perform both color sorting and chemical composition sorting makes them versatile tools that can be adapted to a wide range of applications. This versatility, combined with their precision and efficiency, is a key factor contributing to the growth of the global market for near-infrared optical sorters. As industries continue to evolve and face new challenges, the demand for advanced sorting technologies like NIR optical sorters is expected to increase, further driving market growth.

Glass Industrial, Plastics Industrial, Others in the Near-infrared Optical Sorter - Global Market:

The usage of near-infrared optical sorters in the glass industry is primarily focused on improving the quality and efficiency of glass recycling processes. In this industry, NIR sorters are used to separate different types of glass based on their chemical composition and color. This is crucial because different glass types, such as clear, green, and brown glass, have different recycling processes and end uses. By accurately sorting glass materials, NIR optical sorters help recycling facilities produce higher-quality recycled glass, which can be used to manufacture new glass products. This not only reduces the demand for raw materials but also minimizes the environmental impact of glass production. In the plastics industry, near-infrared optical sorters play a vital role in the recycling process by identifying and separating different types of plastics. Plastics are often challenging to sort due to their similar appearances, but NIR technology can detect subtle differences in their chemical compositions. This allows recycling facilities to efficiently separate plastics such as PET, HDPE, and PVC, which can then be processed and reused in the production of new plastic products. The ability to accurately sort plastics is essential for improving the quality of recycled materials and reducing the environmental impact of plastic waste. In addition to the glass and plastics industries, near-infrared optical sorters are used in various other sectors, including agriculture, mining, and food processing. In agriculture, these sorters are used to separate crops based on their quality and ripeness, ensuring that only the best produce reaches consumers. In mining, NIR sorters help in the extraction of valuable minerals by separating them from less valuable materials. This improves the efficiency of mining operations and reduces the environmental impact of mineral extraction. In the food processing industry, near-infrared optical sorters are used to remove foreign materials and defective products, ensuring that only high-quality food items are packaged and sold. The versatility and efficiency of near-infrared optical sorters make them valuable tools in a wide range of industries, contributing to their growing demand in the global market.

Near-infrared Optical Sorter - Global Market Outlook:

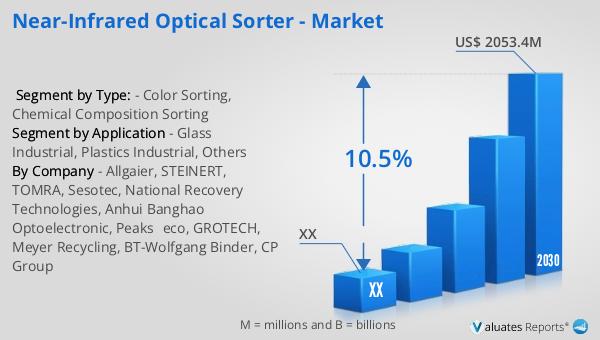

The global market for near-infrared optical sorters was valued at approximately $1,013 million in 2023. It is projected to grow significantly, reaching an estimated size of $2,053.4 million by 2030. This growth represents a compound annual growth rate (CAGR) of 10.5% during the forecast period from 2024 to 2030. The North American market for near-infrared optical sorters also shows promising growth potential, although specific figures for 2023 and 2030 are not provided. The increasing demand for efficient and accurate sorting solutions across various industries is a key driver of this market growth. As industries continue to evolve and face new challenges, the adoption of advanced sorting technologies like near-infrared optical sorters is expected to rise. These machines offer significant advantages in terms of precision, efficiency, and versatility, making them valuable tools for improving operational efficiency and reducing waste. The growing awareness of the environmental benefits of recycling and the need for high-quality recycled materials further contribute to the increasing demand for near-infrared optical sorters in the global market.

| Report Metric | Details |

| Report Name | Near-infrared Optical Sorter - Market |

| Forecasted market size in 2030 | US$ 2053.4 million |

| CAGR | 10.5% |

| Forecasted years | 2024 - 2030 |

| Segment by Type: |

|

| Segment by Application |

|

| By Region |

|

| By Company | Allgaier, STEINERT, TOMRA, Sesotec, National Recovery Technologies, Anhui Banghao Optoelectronic, Peaks-eco, GROTECH, Meyer Recycling, BT-Wolfgang Binder, CP Group |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |