What is Mixing Station Burners - Global Market?

Mixing Station Burners are essential components in various industrial processes, particularly in the construction and infrastructure sectors. These burners are designed to efficiently mix and burn different types of fuels to produce the necessary heat for asphalt production, which is crucial for road construction and maintenance. The global market for Mixing Station Burners is driven by the increasing demand for infrastructure development worldwide. As countries invest in building and upgrading roads, highways, and airports, the need for efficient and reliable mixing station burners grows. These burners are engineered to handle various fuel types, including gas, fuel oil, and pulverized coal, making them versatile and adaptable to different regional fuel availability and environmental regulations. The market is characterized by technological advancements aimed at improving burner efficiency, reducing emissions, and enhancing fuel flexibility. Manufacturers are focusing on developing burners that offer better performance, lower operational costs, and compliance with stringent environmental standards. As a result, the global market for Mixing Station Burners is poised for steady growth, driven by the ongoing expansion of infrastructure projects and the need for sustainable and efficient construction practices.

Gas Fuel, Fuel Oil, Pulverized Coal Fuel in the Mixing Station Burners - Global Market:

Mixing Station Burners are designed to operate with various fuel types, each offering distinct advantages and challenges. Gas fuel is one of the most commonly used fuels in mixing station burners due to its clean-burning properties and availability. Natural gas, in particular, is favored for its low emissions and cost-effectiveness. It provides a consistent and controllable heat source, which is crucial for the precise temperature management required in asphalt production. However, the availability of natural gas can vary by region, influencing its adoption in different markets. Fuel oil, another popular choice, offers high energy density and is often used in areas where gas infrastructure is limited. It provides a reliable heat source but requires careful handling and storage due to its liquid nature. The use of fuel oil can also result in higher emissions compared to gas, necessitating the implementation of emission control technologies. Pulverized coal fuel is less common but is utilized in regions with abundant coal resources. It offers a cost-effective solution but poses challenges in terms of emissions and ash handling. The combustion of pulverized coal requires specialized burners capable of handling solid fuels and ensuring complete combustion to minimize environmental impact. Each fuel type presents unique considerations in terms of cost, availability, and environmental impact, influencing the choice of fuel for mixing station burners in different regions. Manufacturers are continually innovating to develop burners that can efficiently utilize multiple fuel types, providing flexibility and adaptability to meet diverse market needs. The global market for Mixing Station Burners is shaped by these fuel dynamics, with regional preferences and regulatory frameworks playing a significant role in determining the dominant fuel type in each market. As environmental regulations become more stringent, there is a growing emphasis on developing burners that can operate with cleaner fuels and incorporate advanced emission control technologies. This trend is driving research and development efforts aimed at enhancing burner efficiency, reducing emissions, and expanding fuel flexibility. The ability to switch between different fuel types or utilize a combination of fuels offers significant advantages in terms of operational flexibility and cost management. As a result, the market is witnessing increased demand for hybrid burners capable of operating with multiple fuel sources, providing a competitive edge to manufacturers that can offer such solutions. The ongoing evolution of fuel technologies and the push for cleaner and more sustainable energy sources are expected to shape the future of the Mixing Station Burners market, with a focus on innovation and adaptability to meet the changing needs of the construction and infrastructure sectors.

Highway, Airport, Parking Lot, Others in the Mixing Station Burners - Global Market:

Mixing Station Burners play a crucial role in various infrastructure projects, including highways, airports, parking lots, and other construction applications. In highway construction, these burners are used to produce asphalt, which is essential for paving roads and ensuring smooth and durable surfaces. The efficiency and reliability of mixing station burners directly impact the quality of the asphalt produced, influencing the longevity and performance of the roads. As countries invest in expanding and upgrading their highway networks, the demand for high-performance mixing station burners continues to grow. In airport construction, mixing station burners are used to produce the specialized asphalt required for runways and taxiways. The stringent quality and safety standards in airport construction necessitate the use of advanced burners capable of delivering precise temperature control and consistent asphalt quality. The ability to produce high-quality asphalt is critical for ensuring the safety and efficiency of airport operations, making mixing station burners an indispensable component of airport infrastructure projects. Parking lots, although smaller in scale compared to highways and airports, also rely on mixing station burners for asphalt production. The durability and appearance of parking lot surfaces are important considerations for property owners and developers, driving the demand for reliable and efficient burners. In addition to these applications, mixing station burners are used in various other construction projects, such as bridges, tunnels, and urban development initiatives. The versatility of these burners in handling different fuel types and producing high-quality asphalt makes them suitable for a wide range of construction applications. As urbanization and infrastructure development continue to accelerate globally, the demand for mixing station burners is expected to remain strong. The ability to adapt to different project requirements and environmental conditions is a key factor driving the adoption of mixing station burners in diverse construction applications. Manufacturers are focusing on developing burners that offer enhanced performance, fuel efficiency, and compliance with environmental regulations to meet the evolving needs of the construction industry. The global market for Mixing Station Burners is characterized by a growing emphasis on sustainability and innovation, with a focus on developing solutions that can support the construction of resilient and sustainable infrastructure.

Mixing Station Burners - Global Market Outlook:

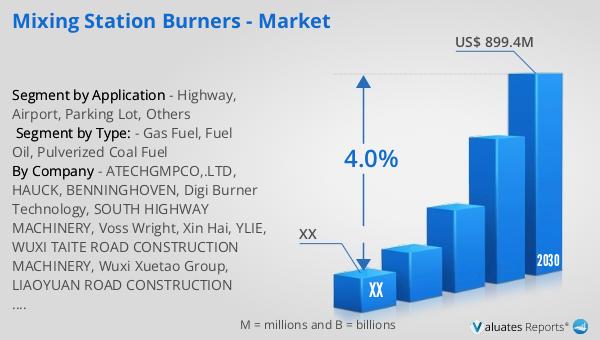

The global market for Mixing Station Burners was valued at approximately $698.3 million in 2023. Projections indicate that this market is set to expand to an adjusted size of around $899.4 million by the year 2030, reflecting a compound annual growth rate (CAGR) of 4.0% during the forecast period from 2024 to 2030. This growth trajectory underscores the increasing demand for efficient and reliable mixing station burners, driven by the ongoing expansion of infrastructure projects worldwide. However, it's important to note that the construction machinery industry faced challenges in 2022, as reported by the China Machinery Industry Federation. The industry's operating income experienced a decline of over 12% during that year. This downturn highlights the volatility and challenges within the construction sector, which can impact the demand for mixing station burners. Despite these challenges, the market outlook for Mixing Station Burners remains positive, supported by the need for sustainable and efficient construction practices. As countries continue to invest in infrastructure development, the demand for high-performance mixing station burners is expected to grow, driven by the need for reliable and efficient solutions in road construction, airport development, and other infrastructure projects. The market's growth is also influenced by technological advancements aimed at improving burner efficiency, reducing emissions, and enhancing fuel flexibility. As a result, the global market for Mixing Station Burners is poised for steady growth, driven by the ongoing expansion of infrastructure projects and the need for sustainable and efficient construction practices.

| Report Metric | Details |

| Report Name | Mixing Station Burners - Market |

| Forecasted market size in 2030 | US$ 899.4 million |

| CAGR | 4.0% |

| Forecasted years | 2024 - 2030 |

| Segment by Type: |

|

| Segment by Application |

|

| By Region |

|

| By Company | ATECHGMPCO,.LTD, HAUCK, BENNINGHOVEN, Digi Burner Technology, SOUTH HIGHWAY MACHINERY, Voss Wright, Xin Hai, YLIE, WUXI TAITE ROAD CONSTRUCTION MACHINERY, Wuxi Xuetao Group, LIAOYUAN ROAD CONSTRUCTION MACHINERY, XINZHU MACHINERY |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |