What is Metalworking Treating Fluid - Global Market?

Metalworking treating fluids are specialized liquids used in the metalworking industry to cool and lubricate tools and workpieces during machining processes. These fluids play a crucial role in reducing friction and heat, which can cause wear and tear on both the tools and the materials being worked on. The global market for metalworking treating fluids is vast and diverse, encompassing a wide range of products tailored to different applications and industries. These fluids are essential in various sectors, including automotive, aerospace, and general manufacturing, where precision and efficiency are paramount. The market is driven by the continuous demand for high-quality metal products and the need for advanced machining techniques. As industries evolve and new materials are developed, the demand for innovative and effective metalworking fluids continues to grow. The market is characterized by a mix of established players and new entrants, all striving to offer products that meet the ever-changing needs of the industry. With advancements in technology and a focus on sustainability, the metalworking treating fluid market is poised for significant growth in the coming years.

Semi-Synthetic Fluids, Synthetic Fluids in the Metalworking Treating Fluid - Global Market:

Semi-synthetic and synthetic fluids are two major categories within the metalworking treating fluid market, each offering distinct advantages and applications. Semi-synthetic fluids are a blend of mineral oils and synthetic components, providing a balance between the lubricating properties of oils and the enhanced performance of synthetic additives. These fluids are particularly popular in applications where moderate to high lubrication is required, such as in the automotive and aerospace industries. They offer excellent cooling properties, reduce tool wear, and improve surface finish, making them ideal for high-speed machining operations. Additionally, semi-synthetic fluids are often more cost-effective than fully synthetic options, making them an attractive choice for many manufacturers. On the other hand, synthetic fluids are entirely composed of chemical compounds, offering superior performance in extreme conditions. They are designed to provide maximum cooling and lubrication, even under high temperatures and pressures. Synthetic fluids are often used in precision machining and grinding operations, where the highest levels of accuracy and surface finish are required. They are also favored in industries where environmental regulations are stringent, as they tend to be more biodegradable and less harmful to the environment. The choice between semi-synthetic and synthetic fluids often depends on the specific requirements of the application, including factors such as cost, performance, and environmental impact. As the metalworking industry continues to evolve, the demand for both types of fluids is expected to grow, driven by the need for more efficient and sustainable machining processes. Manufacturers are continually developing new formulations to meet the changing needs of the industry, incorporating advanced additives and technologies to enhance performance and reduce environmental impact. The global market for semi-synthetic and synthetic metalworking fluids is highly competitive, with numerous players vying for market share. Companies are investing heavily in research and development to create innovative products that offer superior performance and meet the stringent demands of modern manufacturing. As industries become more focused on sustainability and efficiency, the demand for high-performance metalworking fluids is expected to increase, driving growth in the market. The future of the metalworking treating fluid market lies in the development of advanced formulations that offer improved performance, reduced environmental impact, and cost-effectiveness. With ongoing advancements in technology and a growing emphasis on sustainability, the market for semi-synthetic and synthetic metalworking fluids is poised for significant growth in the coming years.

Automobile Industry, General Industry, Others in the Metalworking Treating Fluid - Global Market:

Metalworking treating fluids are indispensable in various industries, with their usage spanning the automobile industry, general industry, and other sectors. In the automobile industry, these fluids are crucial for the manufacturing of components such as engines, transmissions, and body parts. They help in reducing friction and heat during machining processes, ensuring precision and extending the life of tools and machinery. The demand for high-performance vehicles and the push for lightweight materials have further increased the need for advanced metalworking fluids that can handle complex machining tasks. In the general industry, metalworking fluids are used in the production of a wide range of products, from household appliances to industrial machinery. They play a vital role in ensuring the quality and durability of metal components, which are essential for the smooth operation of various machines and equipment. The versatility of metalworking fluids makes them suitable for a variety of applications, from cutting and grinding to drilling and milling. Other sectors, such as aerospace and electronics, also rely heavily on metalworking fluids for the production of high-precision components. In the aerospace industry, for example, these fluids are used in the machining of critical parts such as turbine blades and structural components, where precision and reliability are paramount. The electronics industry, on the other hand, uses metalworking fluids in the production of components such as circuit boards and connectors, where precision and cleanliness are crucial. The global market for metalworking treating fluids is driven by the continuous demand for high-quality metal products and the need for advanced machining techniques. As industries evolve and new materials are developed, the demand for innovative and effective metalworking fluids continues to grow. With advancements in technology and a focus on sustainability, the metalworking treating fluid market is poised for significant growth in the coming years.

Metalworking Treating Fluid - Global Market Outlook:

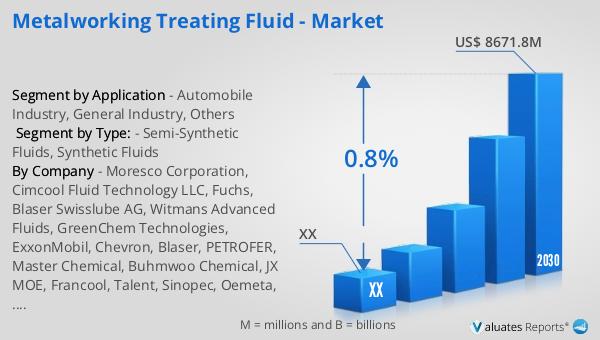

The global market for metalworking treating fluids was valued at approximately $8,319 million in 2023, with projections indicating a growth to around $8,671.8 million by 2030. This growth represents a compound annual growth rate (CAGR) of 0.8% over the forecast period from 2024 to 2030. This modest growth reflects the steady demand for metalworking fluids across various industries, driven by the need for efficient and sustainable machining processes. In North America, the market for metalworking treating fluids is also expected to experience growth, although specific figures were not provided. The region's market dynamics are influenced by the strong presence of the automotive and aerospace industries, which are significant consumers of metalworking fluids. The demand for high-performance fluids that can meet the stringent requirements of these industries is expected to drive market growth in North America. As the global market continues to evolve, companies are focusing on developing innovative products that offer superior performance and meet the changing needs of the industry. With ongoing advancements in technology and a growing emphasis on sustainability, the metalworking treating fluid market is poised for continued growth in the coming years.

| Report Metric | Details |

| Report Name | Metalworking Treating Fluid - Market |

| Forecasted market size in 2030 | US$ 8671.8 million |

| CAGR | 0.8% |

| Forecasted years | 2024 - 2030 |

| Segment by Type: |

|

| Segment by Application |

|

| By Region |

|

| By Company | Moresco Corporation, Cimcool Fluid Technology LLC, Fuchs, Blaser Swisslube AG, Witmans Advanced Fluids, GreenChem Technologies, ExxonMobil, Chevron, Blaser, PETROFER, Master Chemical, Buhmwoo Chemical, JX MOE, Francool, Talent, Sinopec, Oemeta, Milacron, Amer, Peisun, Boer technology |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |