What is Machinery Vibration Monitoring System - Global Market?

Machinery Vibration Monitoring Systems are essential tools used globally to ensure the smooth operation of various machines by detecting and analyzing vibrations. These systems help in identifying potential mechanical issues before they lead to significant failures, thereby saving time and reducing maintenance costs. By continuously monitoring the vibrations of machinery, these systems can detect imbalances, misalignments, and other mechanical faults that might not be visible to the naked eye. The global market for these systems is expanding as industries increasingly recognize the importance of predictive maintenance. With advancements in technology, these systems have become more sophisticated, offering real-time data analysis and remote monitoring capabilities. This has made them indispensable in industries such as manufacturing, oil and gas, and power generation, where machinery downtime can lead to substantial financial losses. As industries continue to adopt automation and smart technologies, the demand for machinery vibration monitoring systems is expected to grow, driven by the need for efficient and reliable machine operation.

Remote Monitoring, Field Monitoring in the Machinery Vibration Monitoring System - Global Market:

Remote monitoring and field monitoring are two critical components of the Machinery Vibration Monitoring System in the global market. Remote monitoring allows for the observation and analysis of machinery vibrations from a distance, using advanced sensors and communication technologies. This capability is particularly beneficial for industries with machinery located in hard-to-reach or hazardous environments, as it eliminates the need for physical presence, thereby enhancing safety and efficiency. Remote monitoring systems can transmit real-time data to centralized control centers, where experts can analyze the information and make informed decisions about maintenance and repairs. This not only reduces downtime but also optimizes resource allocation by ensuring that maintenance activities are carried out only when necessary. On the other hand, field monitoring involves the direct measurement and analysis of vibrations at the machinery's location. This approach is often used in conjunction with remote monitoring to provide a comprehensive understanding of the machine's condition. Field monitoring systems are equipped with portable devices that can be easily deployed to different locations, allowing for on-the-spot diagnostics and troubleshooting. The integration of both remote and field monitoring systems provides a holistic approach to machinery maintenance, ensuring that potential issues are identified and addressed promptly. As the global market for machinery vibration monitoring systems continues to grow, the demand for advanced remote and field monitoring solutions is expected to increase, driven by the need for efficient and reliable machine operation.

Automotive, Aerospace, Electronic, Other in the Machinery Vibration Monitoring System - Global Market:

The usage of Machinery Vibration Monitoring Systems in various industries such as automotive, aerospace, electronics, and others is crucial for maintaining operational efficiency and preventing unexpected machinery failures. In the automotive industry, these systems are used to monitor the vibrations of engines, transmissions, and other critical components. By detecting anomalies in vibration patterns, manufacturers can identify potential issues early and take corrective actions before they lead to costly breakdowns. This not only enhances the reliability of vehicles but also improves customer satisfaction by reducing the likelihood of mechanical failures. In the aerospace industry, machinery vibration monitoring systems play a vital role in ensuring the safety and reliability of aircraft. By continuously monitoring the vibrations of engines, turbines, and other critical components, these systems can detect potential issues that could compromise the safety of the aircraft. This allows for timely maintenance and repairs, reducing the risk of in-flight failures and enhancing passenger safety. In the electronics industry, machinery vibration monitoring systems are used to ensure the smooth operation of manufacturing equipment. By detecting and analyzing vibrations, manufacturers can identify potential issues that could affect the quality and performance of electronic components. This helps in maintaining high production standards and reducing the likelihood of defects. Other industries, such as oil and gas, power generation, and manufacturing, also rely on machinery vibration monitoring systems to ensure the efficient operation of their equipment. By providing real-time data and analysis, these systems enable industries to implement predictive maintenance strategies, reducing downtime and optimizing resource allocation. As the global market for machinery vibration monitoring systems continues to expand, their usage in various industries is expected to increase, driven by the need for efficient and reliable machine operation.

Machinery Vibration Monitoring System - Global Market Outlook:

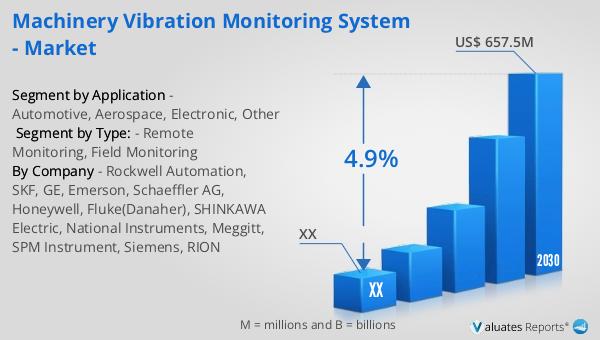

The global market for Machinery Vibration Monitoring Systems was valued at approximately $472.6 million in 2023. It is projected to grow to a revised size of $657.5 million by 2030, reflecting a compound annual growth rate (CAGR) of 4.9% during the forecast period from 2024 to 2030. This growth is indicative of the increasing demand for these systems across various industries, driven by the need for predictive maintenance and efficient machine operation. In North America, the market for Machinery Vibration Monitoring Systems was valued at a significant amount in 2023 and is expected to continue its growth trajectory through 2030. The CAGR for this region during the forecast period is anticipated to be robust, reflecting the strong adoption of these systems in industries such as manufacturing, oil and gas, and power generation. The growth in the North American market is also supported by advancements in technology, which have made these systems more accessible and effective. As industries continue to prioritize operational efficiency and cost savings, the demand for Machinery Vibration Monitoring Systems is expected to rise, contributing to the overall growth of the global market.

| Report Metric | Details |

| Report Name | Machinery Vibration Monitoring System - Market |

| Forecasted market size in 2030 | US$ 657.5 million |

| CAGR | 4.9% |

| Forecasted years | 2024 - 2030 |

| Segment by Type: |

|

| Segment by Application |

|

| By Region |

|

| By Company | Rockwell Automation, SKF, GE, Emerson, Schaeffler AG, Honeywell, Fluke(Danaher), SHINKAWA Electric, National Instruments, Meggitt, SPM Instrument, Siemens, RION |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |