What is Industrial Bolt (Fastener) - Global Market?

Industrial bolts, commonly referred to as fasteners, are essential components in various industries worldwide. These bolts are designed to hold together different parts of machinery, structures, and vehicles, ensuring stability and safety. The global market for industrial bolts is vast and diverse, catering to numerous sectors such as automotive, construction, and machinery manufacturing. The demand for these fasteners is driven by the need for durable and reliable connections in both heavy-duty and light applications. Industrial bolts come in various sizes, materials, and designs to meet specific requirements, including resistance to corrosion, high tensile strength, and the ability to withstand extreme temperatures. As industries continue to expand and innovate, the need for high-quality fasteners grows, making the industrial bolt market a critical component of global manufacturing and construction activities. The market is characterized by continuous advancements in bolt technology, including the development of eco-friendly and high-performance materials, which further enhance the efficiency and sustainability of industrial operations.

Half Screw Bolt, Full Screw Bolt in the Industrial Bolt (Fastener) - Global Market:

Half screw bolts and full screw bolts are two primary types of fasteners used in the industrial bolt market, each serving distinct purposes based on their design and application. Half screw bolts, also known as partially threaded bolts, have threads on only a portion of the shank, with the rest being smooth. This design is particularly useful in applications where alignment and shear strength are crucial. The smooth part of the bolt allows for a snug fit in the unthreaded hole, providing stability and reducing the risk of damage to the materials being fastened. These bolts are commonly used in situations where the bolt needs to pivot or where a precise fit is necessary, such as in machinery assembly and automotive applications. On the other hand, full screw bolts, or fully threaded bolts, have threads running along the entire length of the shank. This design offers maximum grip and is ideal for applications requiring a strong and secure hold. Full screw bolts are often used in construction and heavy machinery, where the bolt needs to withstand significant tension and pressure. The choice between half screw and full screw bolts depends on the specific requirements of the project, including the materials being joined, the load they need to bear, and the environmental conditions they will be exposed to. In the global market, both types of bolts are available in various materials, such as stainless steel, carbon steel, and alloy steel, each offering different levels of strength, corrosion resistance, and durability. Stainless steel bolts, for example, are highly resistant to rust and are ideal for use in marine and outdoor environments, while carbon steel bolts offer high tensile strength and are suitable for heavy-duty applications. The manufacturing process for these bolts involves precision engineering to ensure they meet industry standards and specifications. This includes processes such as cold forging, heat treatment, and surface finishing, which enhance the bolts' performance and longevity. As industries continue to evolve, the demand for specialized bolts that meet specific technical and environmental requirements is increasing, driving innovation and competition in the global industrial bolt market. Manufacturers are investing in research and development to create bolts that are not only stronger and more durable but also more environmentally friendly, using sustainable materials and production methods. This focus on sustainability is becoming increasingly important as industries seek to reduce their environmental impact and comply with stricter regulations. Overall, the global market for half screw and full screw bolts is dynamic and constantly evolving, with manufacturers striving to meet the diverse needs of their customers while maintaining high standards of quality and performance.

Automotive, Machinery, Construction, MRO, Other in the Industrial Bolt (Fastener) - Global Market:

Industrial bolts play a crucial role in various sectors, including automotive, machinery, construction, maintenance, repair, and operations (MRO), and other industries. In the automotive industry, bolts are essential for assembling vehicles, ensuring that all components are securely fastened and can withstand the stresses of driving. They are used in everything from engine assembly to bodywork, providing the necessary strength and stability to keep vehicles safe and reliable. The demand for high-quality bolts in the automotive sector is driven by the need for lightweight yet strong materials that can improve fuel efficiency and reduce emissions. In the machinery industry, bolts are used to assemble and maintain equipment, ensuring that machines operate smoothly and efficiently. They are critical for the structural integrity of machinery, allowing for precise alignment and secure connections. In construction, bolts are used to join structural elements, such as beams and columns, providing the necessary support for buildings and infrastructure. The construction industry relies on bolts that can withstand heavy loads and harsh environmental conditions, making durability and corrosion resistance key factors in bolt selection. In the MRO sector, bolts are used for routine maintenance and repairs, ensuring that equipment and structures remain in good working condition. This includes everything from replacing worn-out parts to reinforcing existing structures, making bolts an essential component of any maintenance toolkit. Other industries, such as aerospace, marine, and electronics, also rely on industrial bolts for various applications, each with its own set of requirements and challenges. In aerospace, for example, bolts must be lightweight yet strong enough to withstand the extreme conditions of flight, while in marine applications, corrosion resistance is a top priority due to the harsh saltwater environment. The electronics industry requires bolts that can provide precise and secure connections without interfering with sensitive electronic components. As industries continue to innovate and expand, the demand for specialized bolts that meet specific technical and environmental requirements is increasing, driving growth in the global industrial bolt market. Manufacturers are responding to this demand by developing new materials and designs that offer improved performance and sustainability, ensuring that bolts remain a vital component of modern industry.

Industrial Bolt (Fastener) - Global Market Outlook:

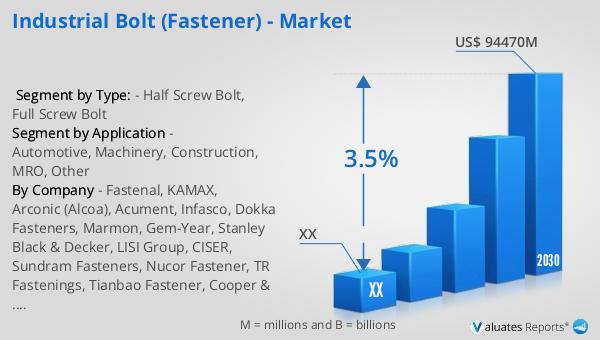

In 2023, the global market for industrial bolt fasteners was valued at approximately $73,770 million. This market is projected to grow, reaching an adjusted size of around $94,470 million by 2030, with a compound annual growth rate (CAGR) of 3.5% during the forecast period from 2024 to 2030. Key players in the global industrial fasteners market include prominent companies such as Würth, PCC, ITW, and Alcoa. These leading manufacturers collectively hold a market share of about 10%, indicating a competitive landscape with numerous players contributing to the market's growth. The steady growth in this market can be attributed to the increasing demand for durable and reliable fasteners across various industries, including automotive, construction, and machinery manufacturing. As industries continue to expand and innovate, the need for high-quality fasteners grows, making the industrial bolt market a critical component of global manufacturing and construction activities. The market is characterized by continuous advancements in bolt technology, including the development of eco-friendly and high-performance materials, which further enhance the efficiency and sustainability of industrial operations. This growth trajectory highlights the importance of industrial bolts in supporting the infrastructure and technological advancements of modern industries, ensuring that they remain a vital component of global economic development.

| Report Metric | Details |

| Report Name | Industrial Bolt (Fastener) - Market |

| Forecasted market size in 2030 | US$ 94470 million |

| CAGR | 3.5% |

| Forecasted years | 2024 - 2030 |

| Segment by Type: |

|

| Segment by Application |

|

| By Region |

|

| By Company | Fastenal, KAMAX, Arconic (Alcoa), Acument, Infasco, Dokka Fasteners, Marmon, Gem-Year, Stanley Black & Decker, LISI Group, CISER, Sundram Fasteners, Nucor Fastener, TR Fastenings, Tianbao Fastener, Cooper & Turner, ATF, XINXING FASTENERS, Ganter, Nitto Seiko, Oglaend System, Penn Engineering, AFI Industries |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |