What is High-purity Aluminum Nitride Powder - Global Market?

High-purity aluminum nitride powder is a specialized material with significant applications across various industries due to its unique properties. This powder is characterized by its high thermal conductivity, electrical insulation, and resistance to corrosion, making it an essential component in advanced technological applications. The global market for high-purity aluminum nitride powder is driven by the increasing demand for efficient thermal management solutions in electronics and other high-tech industries. As devices become more compact and powerful, the need for materials that can effectively dissipate heat without compromising electrical performance becomes critical. High-purity aluminum nitride powder meets these requirements, offering a reliable solution for manufacturers seeking to enhance the performance and longevity of their products. The market is also influenced by advancements in production technologies, which have improved the quality and availability of this material, further expanding its application potential. As industries continue to innovate and seek out materials that offer superior performance, the demand for high-purity aluminum nitride powder is expected to grow, reflecting its importance in the global market landscape.

Direct Nitridation Method, Carbothermal Reduction and Nitridation Method in the High-purity Aluminum Nitride Powder - Global Market:

The production of high-purity aluminum nitride powder involves several sophisticated methods, each with its own advantages and challenges. One of the primary methods is the direct nitridation method, which involves the reaction of aluminum with nitrogen gas at high temperatures. This process is relatively straightforward and cost-effective, making it a popular choice for producing aluminum nitride powder. However, achieving high purity levels can be challenging due to the potential for contamination from impurities in the raw materials or the reaction environment. To mitigate this, stringent controls and high-quality raw materials are essential. Another prevalent method is the carbothermal reduction and nitridation method. This process involves the reduction of aluminum oxide with carbon in a nitrogen atmosphere, resulting in the formation of aluminum nitride. This method is known for producing high-purity powder with excellent thermal and electrical properties, making it highly suitable for advanced applications. However, it requires precise control over reaction conditions, such as temperature and gas flow, to ensure optimal results. The carbothermal reduction and nitridation method is particularly favored in the global market due to its ability to produce high-quality powder consistently. Both methods play a crucial role in meeting the growing demand for high-purity aluminum nitride powder, each offering unique benefits that cater to different industrial needs. As the market continues to evolve, advancements in these production techniques are likely to enhance the quality and efficiency of aluminum nitride powder, further solidifying its position as a vital material in various high-tech applications.

Electrical Component, Thermal Conductive Material, Others in the High-purity Aluminum Nitride Powder - Global Market:

High-purity aluminum nitride powder is utilized in a variety of applications, primarily due to its exceptional thermal and electrical properties. In the realm of electrical components, this powder is indispensable for the production of substrates and insulators. Its high thermal conductivity ensures efficient heat dissipation, which is crucial for maintaining the performance and reliability of electronic devices. This makes it an ideal material for use in semiconductors, LEDs, and other electronic components where heat management is a critical concern. Additionally, its electrical insulation properties prevent short circuits and enhance the overall safety and efficiency of electronic systems. Beyond electrical components, high-purity aluminum nitride powder is also used as a thermal conductive material in various industries. Its ability to conduct heat efficiently makes it a preferred choice for applications requiring effective thermal management, such as in heat sinks and thermal interface materials. This is particularly important in industries like telecommunications and automotive, where maintaining optimal operating temperatures is essential for device performance and longevity. Furthermore, the powder's resistance to chemical corrosion and thermal shock makes it suitable for use in harsh environments, expanding its application scope. Other uses of high-purity aluminum nitride powder include its role in advanced ceramics and composites, where it enhances the mechanical properties and thermal stability of the final products. Its versatility and performance characteristics make it a valuable material across multiple sectors, driving its demand in the global market. As industries continue to seek materials that offer superior performance and reliability, the applications of high-purity aluminum nitride powder are expected to expand, further underscoring its significance in modern technology.

High-purity Aluminum Nitride Powder - Global Market Outlook:

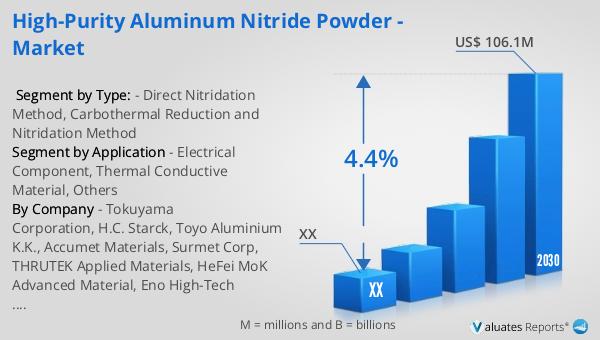

The global market for high-purity aluminum nitride powder was valued at approximately $78 million in 2023, with projections indicating a growth to around $106.1 million by 2030. This growth is expected to occur at a compound annual growth rate (CAGR) of 4.4% from 2024 to 2030. The market is dominated by key players such as Tokuyama Corporation, Surmet Corp, H.C. Starck, and Toyo Aluminium K.K., with the top four manufacturers collectively holding about 85% of the market share. Among the various production methods, the carbothermal reduction and nitridation method is the most prevalent, accounting for over 90% of the market share. This method's dominance is attributed to its ability to produce high-quality aluminum nitride powder with superior thermal and electrical properties, making it highly suitable for advanced technological applications. The market's growth is driven by the increasing demand for efficient thermal management solutions in electronics and other high-tech industries, as well as advancements in production technologies that have improved the quality and availability of high-purity aluminum nitride powder. As industries continue to innovate and seek out materials that offer superior performance, the demand for high-purity aluminum nitride powder is expected to grow, reflecting its importance in the global market landscape.

| Report Metric | Details |

| Report Name | High-purity Aluminum Nitride Powder - Market |

| Forecasted market size in 2030 | US$ 106.1 million |

| CAGR | 4.4% |

| Forecasted years | 2024 - 2030 |

| Segment by Type: |

|

| Segment by Application |

|

| By Region |

|

| By Company | Tokuyama Corporation, H.C. Starck, Toyo Aluminium K.K., Accumet Materials, Surmet Corp, THRUTEK Applied Materials, HeFei MoK Advanced Material, Eno High-Tech Material, Pengcheng Special Ceramics, Desunmet Ceramic Material, Maite Kechuang |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |