What is Fully Automatic Plate Rolling Machine - Global Market?

A Fully Automatic Plate Rolling Machine is a sophisticated piece of industrial equipment designed to bend and shape metal plates into cylindrical or conical forms with minimal human intervention. These machines are integral to industries that require precise and efficient metal forming processes. The global market for these machines is driven by the increasing demand for automation in manufacturing processes, which enhances productivity and reduces labor costs. Fully automatic plate rolling machines are equipped with advanced features such as programmable logic controllers (PLCs) and computer numerical control (CNC) systems, allowing for precise control over the rolling process. This automation ensures consistent quality and reduces the likelihood of human error. The machines are used in various sectors, including automotive, aerospace, and construction, where they contribute to the production of components like pipes, tanks, and structural elements. As industries continue to seek ways to improve efficiency and product quality, the demand for fully automatic plate rolling machines is expected to grow, making them a crucial component of modern manufacturing operations.

Two Roll Plate Rolling Machine, Three Roll Plate Rolling Machine, Four Roll Plate Rolling Machine in the Fully Automatic Plate Rolling Machine - Global Market:

The Fully Automatic Plate Rolling Machine market encompasses various types of machines, each designed to meet specific industrial needs. Among these, the Two Roll Plate Rolling Machine is the simplest form, consisting of two rollers that work together to bend metal plates. This type is typically used for lighter and thinner materials, offering a straightforward and cost-effective solution for basic rolling tasks. However, its simplicity limits its ability to handle more complex shapes or thicker materials. On the other hand, the Three Roll Plate Rolling Machine introduces an additional roller, providing more versatility and precision. This configuration allows for better control over the bending process, making it suitable for a wider range of materials and thicknesses. The three-roll design is particularly effective for creating cylindrical shapes and is commonly used in industries such as automotive and construction. The Four Roll Plate Rolling Machine represents the most advanced configuration, featuring four rollers that offer unparalleled precision and control. This type is ideal for handling heavy-duty materials and complex shapes, making it a preferred choice for industries that require high precision and efficiency, such as aerospace and shipbuilding. The four-roll design allows for pre-bending and rolling in a single pass, significantly reducing production time and improving accuracy. Each type of machine plays a vital role in the global market, catering to different industrial needs and contributing to the overall growth of the plate rolling machine industry. As technology advances, these machines continue to evolve, offering enhanced features and capabilities that meet the ever-changing demands of modern manufacturing.

Petroleum Gas, Household Appliances, Shipbuilding, Energy Field, Transportation, Military and Aviation, Others in the Fully Automatic Plate Rolling Machine - Global Market:

Fully Automatic Plate Rolling Machines are utilized across various industries, each benefiting from the machine's ability to efficiently shape metal plates. In the petroleum and gas sector, these machines are essential for manufacturing pipelines and storage tanks, which require precise and durable construction to withstand harsh environments. The ability to produce large, seamless cylindrical shapes makes these machines invaluable for this industry. In the realm of household appliances, fully automatic plate rolling machines contribute to the production of components like washing machine drums and oven bodies, where uniformity and precision are crucial for product performance and safety. The shipbuilding industry relies heavily on these machines to form the hulls and other structural components of ships, where the ability to handle large and thick metal plates is essential. In the energy field, these machines are used to create components for wind turbines and other renewable energy systems, where precision and durability are key. The transportation industry benefits from these machines in the production of vehicle parts, such as exhaust systems and chassis components, where consistent quality and efficiency are paramount. In the military and aviation sectors, fully automatic plate rolling machines are used to manufacture components that require high precision and strength, such as aircraft fuselages and armored vehicle parts. Other industries, including construction and heavy machinery, also utilize these machines to produce a wide range of components, highlighting their versatility and importance in modern manufacturing. The widespread use of fully automatic plate rolling machines across these diverse sectors underscores their critical role in enhancing productivity and ensuring the quality of metal-formed products.

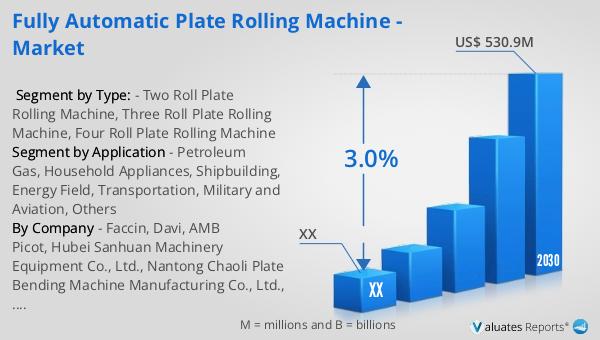

Fully Automatic Plate Rolling Machine - Global Market Outlook:

The global market outlook for Fully Automatic Plate Rolling Machines indicates a promising growth trajectory. In 2023, the market was valued at approximately US$ 435.7 million, reflecting the increasing demand for automation in metal forming processes. By 2030, the market is projected to reach a size of US$ 530.9 million, growing at a compound annual growth rate (CAGR) of 3.0% during the forecast period from 2024 to 2030. This growth is driven by the need for efficient and precise metal forming solutions across various industries, including automotive, aerospace, and construction. The North American market, in particular, is expected to experience significant growth, although specific figures were not provided. The adoption of advanced technologies, such as programmable logic controllers (PLCs) and computer numerical control (CNC) systems, is anticipated to further drive market expansion by enhancing the capabilities and efficiency of these machines. As industries continue to prioritize automation and precision in their manufacturing processes, the demand for fully automatic plate rolling machines is likely to increase, solidifying their position as a vital component of modern industrial operations.

| Report Metric | Details |

| Report Name | Fully Automatic Plate Rolling Machine - Market |

| Forecasted market size in 2030 | US$ 530.9 million |

| CAGR | 3.0% |

| Forecasted years | 2024 - 2030 |

| Segment by Type: |

|

| Segment by Application |

|

| By Region |

|

| By Company | Faccin, Davi, AMB Picot, Hubei Sanhuan Machinery Equipment Co., Ltd., Nantong Chaoli Plate Bending Machine Manufacturing Co., Ltd., Nanjing Claus CNC Machinery Co., Ltd., Haeusler, Sahinler, Imcar, Akyapak, Uzma Machinery, Wuxi Shenchong Forging Machine Tool Co., Ltd., Roccia, Himalaya Machine, lian xian machinery co., ltd. |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |