What is Anti-static Sweeper Nozzle with Metal Fitting - Global Market?

The Anti-static Sweeper Nozzle with Metal Fitting is a specialized tool designed to address static electricity issues in various industrial applications. This nozzle is engineered to prevent the buildup of static charges, which can be a significant problem in environments where dust and particles are prevalent. The metal fitting ensures durability and a secure connection to various equipment, making it a reliable choice for industries that require precise and efficient cleaning solutions. The global market for this product is expanding as industries recognize the importance of maintaining clean and static-free environments to enhance operational efficiency and safety. The demand for anti-static solutions is driven by sectors such as manufacturing, electronics, and pharmaceuticals, where even a small static charge can lead to significant disruptions or damage. As industries continue to evolve and prioritize safety and efficiency, the Anti-static Sweeper Nozzle with Metal Fitting is becoming an essential component in their toolkit. The market's growth is also fueled by technological advancements that improve the nozzle's performance and adaptability to different industrial needs. Overall, the Anti-static Sweeper Nozzle with Metal Fitting is a critical tool in the global market, addressing the ever-growing need for effective static management solutions.

Round, Flat in the Anti-static Sweeper Nozzle with Metal Fitting - Global Market:

The Anti-static Sweeper Nozzle with Metal Fitting is available in various designs, including round and flat configurations, each serving distinct purposes in industrial applications. The round nozzle is typically used in scenarios where a concentrated and powerful stream of air or liquid is required. Its design allows for a focused discharge, making it ideal for tasks that require precision, such as cleaning intricate machinery parts or targeting specific areas with high dust accumulation. The round nozzle's ability to deliver a concentrated flow ensures that static charges are effectively neutralized, reducing the risk of static-related issues in sensitive environments. On the other hand, the flat nozzle is designed to cover a broader area, making it suitable for applications that require a wide sweep. This design is particularly beneficial in environments where large surfaces need to be cleaned or treated, such as factory floors or large equipment surfaces. The flat nozzle's ability to disperse air or liquid over a wide area ensures that static charges are evenly neutralized, providing a comprehensive solution to static management. Both round and flat nozzles are equipped with metal fittings, ensuring durability and a secure connection to various equipment. The metal fitting not only enhances the nozzle's longevity but also ensures that it can withstand the rigors of industrial use. This durability is crucial in environments where equipment is subjected to constant use and potential wear and tear. The choice between round and flat nozzles depends largely on the specific needs of the application. Industries that require precision and targeted cleaning may opt for the round nozzle, while those that need to cover larger areas may find the flat nozzle more suitable. Regardless of the design, both types of nozzles play a vital role in maintaining clean and static-free environments, contributing to the overall efficiency and safety of industrial operations. As the global market for Anti-static Sweeper Nozzles with Metal Fittings continues to grow, manufacturers are investing in research and development to enhance the performance and versatility of these products. Innovations in materials and design are leading to nozzles that are more efficient, durable, and adaptable to a wider range of applications. This ongoing development ensures that industries have access to the most advanced tools for managing static electricity, ultimately improving their operational efficiency and safety. In conclusion, the round and flat designs of the Anti-static Sweeper Nozzle with Metal Fitting offer distinct advantages for different industrial applications. Whether it's the precision of the round nozzle or the broad coverage of the flat nozzle, these tools are essential for maintaining static-free environments in various industries. As the market continues to evolve, these nozzles will remain a critical component in the toolkit of industries worldwide, addressing the ever-growing need for effective static management solutions.

Humidification, Cooling, Dust Removal, Spraying, Disinfection in the Anti-static Sweeper Nozzle with Metal Fitting - Global Market:

The Anti-static Sweeper Nozzle with Metal Fitting is a versatile tool used in various industrial applications, including humidification, cooling, dust removal, spraying, and disinfection. In humidification, the nozzle plays a crucial role in maintaining optimal humidity levels in industrial environments. By dispersing a fine mist of water, the nozzle helps to prevent the buildup of static electricity, which can be exacerbated by dry conditions. This is particularly important in industries such as electronics and textiles, where static charges can lead to significant disruptions or damage. The nozzle's ability to evenly distribute moisture ensures that humidity levels are maintained consistently, reducing the risk of static-related issues. In cooling applications, the Anti-static Sweeper Nozzle with Metal Fitting is used to direct a stream of air or liquid to specific areas that require temperature regulation. This is essential in industries where machinery and equipment generate significant heat during operation. By effectively cooling these areas, the nozzle helps to prevent overheating and potential equipment failure, ensuring smooth and efficient operations. The nozzle's design allows for precise targeting, making it an ideal choice for cooling applications that require accuracy and control. Dust removal is another critical application of the Anti-static Sweeper Nozzle with Metal Fitting. In environments where dust and particles are prevalent, the nozzle is used to blow away debris and prevent the accumulation of static charges. This is particularly important in industries such as manufacturing and pharmaceuticals, where dust can interfere with production processes and compromise product quality. The nozzle's ability to deliver a powerful stream of air ensures that dust is effectively removed, maintaining a clean and static-free environment. In spraying applications, the Anti-static Sweeper Nozzle with Metal Fitting is used to apply coatings or treatments to surfaces. The nozzle's design allows for even distribution of the spray, ensuring that surfaces are uniformly coated. This is essential in industries such as automotive and aerospace, where precise application of coatings is critical to product performance and durability. The nozzle's ability to deliver a consistent spray pattern ensures that coatings are applied efficiently and effectively, reducing waste and improving overall quality. Finally, in disinfection applications, the Anti-static Sweeper Nozzle with Metal Fitting is used to apply disinfectants to surfaces, ensuring that they are thoroughly sanitized. This is particularly important in industries such as healthcare and food processing, where hygiene is paramount. The nozzle's ability to deliver a fine mist ensures that disinfectants are evenly distributed, providing comprehensive coverage and effective disinfection. In conclusion, the Anti-static Sweeper Nozzle with Metal Fitting is a versatile tool that plays a critical role in various industrial applications. Whether it's humidification, cooling, dust removal, spraying, or disinfection, the nozzle's design and functionality ensure that it meets the diverse needs of industries worldwide. As the global market for this product continues to grow, its importance in maintaining clean, efficient, and safe industrial environments cannot be overstated.

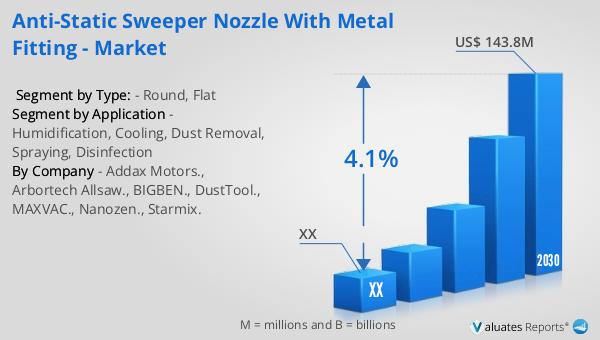

Anti-static Sweeper Nozzle with Metal Fitting - Global Market Outlook:

The global market for the Anti-static Sweeper Nozzle with Metal Fitting was valued at approximately $87 million in 2023. It is projected to grow to a revised size of around $143.8 million by 2030, reflecting a compound annual growth rate (CAGR) of 4.1% during the forecast period from 2024 to 2030. This growth indicates a steady increase in demand for these nozzles, driven by their essential role in managing static electricity across various industries. The North American market, in particular, is expected to see significant growth, although specific figures for 2023 and 2030 are not provided. The anticipated growth in this region underscores the increasing recognition of the importance of static management solutions in industrial operations. The market's expansion is likely fueled by technological advancements and the growing need for efficient and reliable tools to maintain clean and static-free environments. As industries continue to prioritize safety and efficiency, the demand for Anti-static Sweeper Nozzles with Metal Fittings is expected to rise, contributing to the overall growth of the global market. This positive market outlook highlights the critical role these nozzles play in enhancing operational efficiency and safety across various sectors.

| Report Metric | Details |

| Report Name | Anti-static Sweeper Nozzle with Metal Fitting - Market |

| Forecasted market size in 2030 | US$ 143.8 million |

| CAGR | 4.1% |

| Forecasted years | 2024 - 2030 |

| Segment by Type: |

|

| Segment by Application |

|

| By Region |

|

| By Company | Addax Motors., Arbortech Allsaw., BIGBEN., DustTool., MAXVAC., Nanozen., Starmix. |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |