What is Fully Automatic Carton Sealing Machine - Global Market?

The Fully Automatic Carton Sealing Machine is a sophisticated piece of equipment designed to efficiently seal cartons in various industries. This machine automates the process of sealing boxes, which is crucial for businesses that handle large volumes of packaging. By using this machine, companies can significantly reduce labor costs and increase productivity. The global market for these machines is expanding as more industries recognize the benefits of automation in packaging. These machines are equipped with advanced features that allow them to handle different sizes and types of cartons, ensuring a tight and secure seal every time. The demand for fully automatic carton sealing machines is driven by the need for faster and more reliable packaging solutions, especially in industries like food, pharmaceuticals, and logistics. As technology continues to advance, these machines are becoming more efficient and easier to integrate into existing production lines, making them an attractive investment for businesses looking to streamline their operations.

Adhesive Tape, Hot-melt Glue, Others in the Fully Automatic Carton Sealing Machine - Global Market:

In the realm of fully automatic carton sealing machines, adhesive tape, hot-melt glue, and other sealing methods play a pivotal role in determining the efficiency and effectiveness of the sealing process. Adhesive tape is one of the most commonly used sealing methods due to its simplicity and cost-effectiveness. It involves using pressure-sensitive tape to seal the flaps of cartons, providing a quick and reliable seal. This method is particularly popular in industries where speed and ease of use are paramount. The adhesive tape used in these machines is designed to withstand various environmental conditions, ensuring that the seal remains intact during transit and storage. On the other hand, hot-melt glue offers a more robust sealing solution. This method involves applying a thermoplastic adhesive that melts when heated and solidifies upon cooling, creating a strong bond between the carton flaps. Hot-melt glue is ideal for applications where a more secure seal is required, such as in the packaging of heavy or bulky items. It is also favored in industries where the aesthetic appearance of the packaging is important, as it provides a clean and professional finish. Additionally, hot-melt glue can be used on a variety of carton materials, making it a versatile option for businesses with diverse packaging needs. Beyond adhesive tape and hot-melt glue, there are other sealing methods employed by fully automatic carton sealing machines. These include water-activated tape, which is known for its tamper-evident properties, and ultrasonic sealing, which uses high-frequency vibrations to create a bond between carton flaps. Each of these methods has its own set of advantages and is chosen based on the specific requirements of the packaging application. The choice of sealing method is influenced by factors such as the type of product being packaged, the desired level of security, and the environmental conditions the package will be exposed to. As the global market for fully automatic carton sealing machines continues to grow, manufacturers are investing in research and development to enhance the capabilities of these machines. This includes improving the efficiency of the sealing process, reducing energy consumption, and developing new sealing materials that offer better performance and sustainability. The integration of advanced technologies, such as sensors and automation software, is also playing a crucial role in optimizing the sealing process and ensuring consistent quality. In conclusion, the choice of sealing method in fully automatic carton sealing machines is a critical factor that impacts the overall performance and reliability of the packaging process. Adhesive tape, hot-melt glue, and other sealing methods each offer unique benefits and are selected based on the specific needs of the application. As the demand for efficient and reliable packaging solutions continues to rise, the global market for fully automatic carton sealing machines is poised for significant growth, driven by advancements in sealing technology and the increasing adoption of automation in packaging operations.

Food Industrial, Pharmaceutical Industrial, Hardware Industrial, Machinery Industrial, Others in the Fully Automatic Carton Sealing Machine - Global Market:

Fully automatic carton sealing machines are widely used across various industries due to their ability to enhance efficiency and ensure consistent packaging quality. In the food industry, these machines play a crucial role in maintaining the integrity and safety of packaged products. They are used to seal cartons containing a wide range of food items, from dry goods to perishable products. The use of fully automatic carton sealing machines in the food industry helps to minimize the risk of contamination and spoilage by providing a secure and tamper-evident seal. This is particularly important for products that require strict adherence to hygiene and safety standards. In the pharmaceutical industry, fully automatic carton sealing machines are essential for ensuring the safe and secure packaging of medicines and medical supplies. These machines provide a reliable seal that protects the contents from environmental factors such as moisture and dust, which can compromise the efficacy of pharmaceutical products. The use of fully automatic carton sealing machines in this industry also helps to prevent tampering and counterfeiting, which are significant concerns in the pharmaceutical sector. In the hardware industry, fully automatic carton sealing machines are used to package a variety of tools and equipment. These machines provide a strong and durable seal that can withstand the rigors of transportation and handling. This is particularly important for heavy or bulky items that require additional protection during transit. The use of fully automatic carton sealing machines in the hardware industry helps to ensure that products reach their destination in optimal condition, reducing the risk of damage and returns. In the machinery industry, fully automatic carton sealing machines are used to package large and complex machinery components. These machines provide a secure seal that protects the contents from environmental factors and ensures that they remain intact during transportation. The use of fully automatic carton sealing machines in this industry helps to streamline the packaging process and improve overall efficiency. Beyond these industries, fully automatic carton sealing machines are also used in a variety of other sectors, including logistics, electronics, and consumer goods. In each of these industries, the use of fully automatic carton sealing machines helps to improve packaging efficiency, reduce labor costs, and ensure consistent quality. As the demand for efficient and reliable packaging solutions continues to grow, the global market for fully automatic carton sealing machines is expected to expand, driven by advancements in technology and the increasing adoption of automation in packaging operations.

Fully Automatic Carton Sealing Machine - Global Market Outlook:

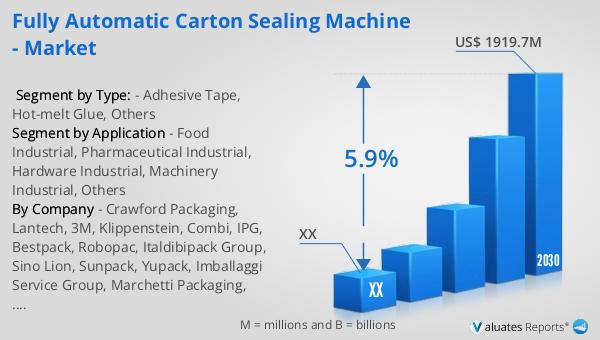

The global market for fully automatic carton sealing machines was valued at approximately US$ 1315 million in 2023. It is projected to grow to a revised size of US$ 1919.7 million by 2030, with a compound annual growth rate (CAGR) of 5.9% during the forecast period from 2024 to 2030. This market is witnessing a trend of increasing demand, driven by rapid technological advancements and a geographical concentration in major manufacturing countries. As industry standards continue to improve, the adoption of fully automatic carton sealing machines is expected to rise, further fueling market growth. The increasing demand for efficient and reliable packaging solutions is a key factor driving the growth of the fully automatic carton sealing machine market. As businesses strive to enhance productivity and reduce labor costs, the adoption of automation in packaging operations is becoming increasingly prevalent. This trend is particularly evident in industries such as food, pharmaceuticals, and logistics, where the need for fast and secure packaging solutions is paramount. The geographical distribution of the fully automatic carton sealing machine market is concentrated in large manufacturing countries, where the demand for advanced packaging solutions is high. These countries are investing in research and development to enhance the capabilities of fully automatic carton sealing machines, driving innovation and growth in the market. As industry standards continue to improve, the adoption of fully automatic carton sealing machines is expected to rise, further fueling market growth. In conclusion, the global market for fully automatic carton sealing machines is poised for significant growth, driven by increasing demand, rapid technological advancements, and the gradual improvement of industry standards. As businesses continue to seek efficient and reliable packaging solutions, the adoption of fully automatic carton sealing machines is expected to rise, further fueling market growth.

| Report Metric | Details |

| Report Name | Fully Automatic Carton Sealing Machine - Market |

| Forecasted market size in 2030 | US$ 1919.7 million |

| CAGR | 5.9% |

| Forecasted years | 2024 - 2030 |

| Segment by Type: |

|

| Segment by Application |

|

| By Region |

|

| By Company | Crawford Packaging, Lantech, 3M, Klippenstein, Combi, IPG, Bestpack, Robopac, Italdibipack Group, Sino Lion, Sunpack, Yupack, Imballaggi Service Group, Marchetti Packaging, Panotec, DS Smith |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |