What is Fully Automatic Biscuit Production Equipment - Global Market?

Fully automatic biscuit production equipment represents a significant advancement in the global food processing industry. This equipment is designed to streamline the entire biscuit manufacturing process, from mixing ingredients to baking and packaging, without the need for manual intervention. The global market for this equipment is driven by the increasing demand for biscuits, which are a popular snack worldwide. Manufacturers are investing in fully automatic systems to enhance production efficiency, reduce labor costs, and maintain consistent product quality. These systems are equipped with advanced technologies such as programmable logic controllers (PLCs), sensors, and robotics, which ensure precise control over the production process. The equipment is capable of producing a wide variety of biscuit types, including cookies, crackers, and wafers, catering to diverse consumer preferences. As the demand for convenience foods continues to rise, the adoption of fully automatic biscuit production equipment is expected to grow, offering manufacturers a competitive edge in the market.

Small, Medium, Large in the Fully Automatic Biscuit Production Equipment - Global Market:

In the global market for fully automatic biscuit production equipment, businesses are categorized into small, medium, and large based on their production capacity and scale of operations. Small-scale manufacturers typically operate with limited resources and focus on niche markets or local distribution. They often invest in compact, cost-effective equipment that can produce a modest volume of biscuits while maintaining quality. These small businesses benefit from the flexibility of fully automatic systems, which allow them to experiment with different recipes and product variations without significant downtime. Medium-sized manufacturers, on the other hand, have a more extensive production capacity and often serve regional or national markets. They require equipment that can handle larger batches and offer greater efficiency to meet growing consumer demand. For these manufacturers, fully automatic systems provide the necessary scalability and reliability to expand their product lines and increase market share. Large-scale manufacturers dominate the global biscuit market, producing vast quantities of biscuits for international distribution. These companies invest heavily in state-of-the-art fully automatic equipment to maximize production speed and minimize operational costs. The equipment used by large manufacturers is often customized to meet specific production requirements and integrate seamlessly with existing systems. This level of automation enables them to maintain a competitive advantage by consistently delivering high-quality products at a lower cost. Across all scales, the adoption of fully automatic biscuit production equipment is driven by the need for efficiency, consistency, and innovation in a highly competitive market. As consumer preferences evolve and demand for diverse biscuit varieties increases, manufacturers of all sizes are leveraging advanced technology to stay ahead. The global market for fully automatic biscuit production equipment is characterized by rapid technological advancements and a focus on sustainability. Manufacturers are increasingly incorporating eco-friendly practices and energy-efficient technologies into their production processes to reduce their environmental impact. This shift towards sustainable production is not only driven by regulatory requirements but also by consumer demand for environmentally responsible products. In conclusion, the global market for fully automatic biscuit production equipment is diverse and dynamic, with small, medium, and large manufacturers each playing a crucial role in meeting the growing demand for biscuits worldwide. By investing in advanced automation technologies, these manufacturers can enhance their production capabilities, improve product quality, and remain competitive in an ever-evolving market.

Business, Industry in the Fully Automatic Biscuit Production Equipment - Global Market:

The usage of fully automatic biscuit production equipment in business and industry is transforming the way biscuits are manufactured and distributed globally. In the business sector, companies are leveraging this equipment to streamline operations, reduce costs, and increase profitability. Fully automatic systems eliminate the need for manual labor in the production process, allowing businesses to allocate resources more efficiently and focus on strategic growth initiatives. This automation also reduces the risk of human error, ensuring consistent product quality and enhancing brand reputation. For businesses, investing in fully automatic biscuit production equipment is a strategic decision that can lead to significant competitive advantages in the market. In the industrial sector, the adoption of fully automatic biscuit production equipment is driven by the need for high-volume production and operational efficiency. Industries that produce biscuits on a large scale require equipment that can handle continuous production cycles without compromising on quality. Fully automatic systems are designed to meet these demands, offering features such as high-speed mixing, precise baking control, and automated packaging. These capabilities enable industries to meet the growing consumer demand for biscuits while maintaining cost-effectiveness and product consistency. Furthermore, the integration of advanced technologies such as IoT and AI in fully automatic systems allows for real-time monitoring and data analysis, enabling industries to optimize production processes and improve overall efficiency. The use of fully automatic biscuit production equipment also supports sustainability initiatives in both business and industry. By reducing energy consumption and minimizing waste, these systems contribute to more environmentally friendly production practices. This aligns with the increasing consumer preference for sustainable products and helps businesses and industries meet regulatory requirements related to environmental impact. In summary, the usage of fully automatic biscuit production equipment in business and industry is revolutionizing the biscuit manufacturing process. By enhancing efficiency, reducing costs, and supporting sustainability, these systems provide significant benefits to manufacturers and contribute to the growth of the global biscuit market.

Fully Automatic Biscuit Production Equipment - Global Market Outlook:

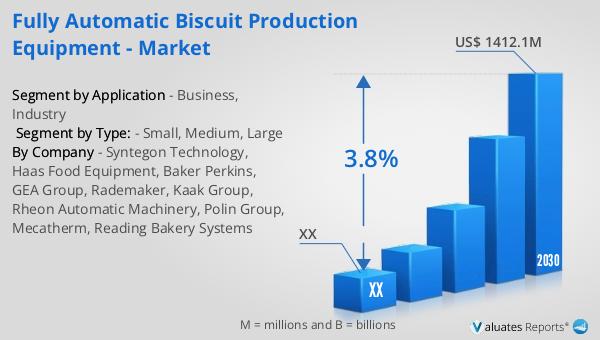

The global market for fully automatic biscuit production equipment was valued at approximately US$ 1002 million in 2023. It is projected to grow to a revised size of US$ 1412.1 million by 2030, with a compound annual growth rate (CAGR) of 3.8% during the forecast period from 2024 to 2030. This growth is driven by the increasing demand for automation in the biscuit production process, which enhances operational efficiency and product quality. Fully automatic biscuit production equipment is essential for achieving seamless and efficient production, as it automates various stages of the manufacturing process, from ingredient mixing to baking and packaging. The equipment's ability to operate continuously without manual intervention significantly reduces labor costs and minimizes the risk of human error, ensuring consistent product quality. As manufacturers seek to meet the growing consumer demand for biscuits, the adoption of fully automatic systems is expected to increase, providing a competitive edge in the market. This trend underscores the importance of investing in advanced automation technologies to remain competitive in the evolving global biscuit market.

| Report Metric | Details |

| Report Name | Fully Automatic Biscuit Production Equipment - Market |

| Forecasted market size in 2030 | US$ 1412.1 million |

| CAGR | 3.8% |

| Forecasted years | 2024 - 2030 |

| Segment by Type: |

|

| Segment by Application |

|

| By Region |

|

| By Company | Syntegon Technology, Haas Food Equipment, Baker Perkins, GEA Group, Rademaker, Kaak Group, Rheon Automatic Machinery, Polin Group, Mecatherm, Reading Bakery Systems |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |