What is Friction Welding Equipment - Global Market?

Friction welding equipment is a fascinating segment of the global market that focuses on a unique welding process. Unlike traditional welding methods that rely on melting materials to join them, friction welding uses mechanical friction to generate heat between two surfaces. This heat softens the materials, allowing them to be joined under pressure without melting. This method is particularly advantageous because it produces high-quality welds with minimal defects and is suitable for joining dissimilar materials. The global market for friction welding equipment is driven by its applications across various industries, including automotive, aerospace, and manufacturing. As industries continue to seek efficient and reliable welding solutions, the demand for friction welding equipment is expected to grow. This market encompasses a range of equipment types, each designed to cater to specific welding needs, making it a versatile and essential component of modern manufacturing processes. The market's growth is supported by technological advancements and the increasing adoption of automation in manufacturing, which enhances the efficiency and precision of friction welding processes.

Rotary Friction Welding, Linear Friction Welding, Friction Stir Welding in the Friction Welding Equipment - Global Market:

Rotary friction welding, linear friction welding, and friction stir welding are three primary types of friction welding processes, each with distinct characteristics and applications. Rotary friction welding is one of the most common methods, where one workpiece is rotated while the other is held stationary. The friction generated at the interface of the two pieces creates heat, allowing them to be joined under pressure. This method is widely used in the automotive industry for joining drive shafts, axles, and other cylindrical components due to its ability to produce strong, reliable joints quickly. Linear friction welding, on the other hand, involves the linear motion of one workpiece against another. This process is particularly useful for joining complex shapes and is often employed in the aerospace industry for manufacturing components like blisks and turbine blades. The precision and strength of the welds produced by linear friction welding make it ideal for high-performance applications where safety and reliability are paramount. Friction stir welding is a relatively newer technique that involves a rotating tool that moves along the joint line of two workpieces. The frictional heat generated by the tool softens the material, allowing it to be stirred together to form a solid-state weld. This method is highly effective for joining aluminum and other non-ferrous metals and is commonly used in the aerospace and shipbuilding industries. Friction stir welding is valued for its ability to produce high-quality welds with minimal distortion and excellent mechanical properties. Each of these friction welding techniques offers unique advantages, making them suitable for a wide range of applications across different industries. As the global market for friction welding equipment continues to expand, these methods are expected to play a crucial role in advancing manufacturing technologies and meeting the evolving needs of various sectors.

Automotive Manufacturing, Tool & Machine Manufacturing, Aviation & Shipbuilding in the Friction Welding Equipment - Global Market:

Friction welding equipment plays a significant role in several key industries, including automotive manufacturing, tool and machine manufacturing, and aviation and shipbuilding. In the automotive sector, friction welding is used extensively to join components such as drive shafts, axles, and steering columns. The ability to produce strong, reliable joints quickly makes friction welding an ideal choice for high-volume automotive production. Additionally, the process's capability to join dissimilar materials, such as aluminum to steel, is particularly beneficial in the automotive industry, where lightweight materials are increasingly used to improve fuel efficiency. In tool and machine manufacturing, friction welding is employed to create durable, high-strength joints in cutting tools, drill bits, and other precision instruments. The process's ability to produce defect-free welds with excellent mechanical properties ensures the longevity and performance of these tools, which are essential for various industrial applications. In the aviation and shipbuilding industries, friction welding is used to manufacture critical components such as turbine blades, blisks, and ship hulls. The precision and strength of the welds produced by friction welding are crucial for ensuring the safety and reliability of aircraft and ships. Moreover, the process's ability to join complex shapes and dissimilar materials makes it an invaluable tool for these industries, where performance and safety are of utmost importance. As the global market for friction welding equipment continues to grow, its applications in these industries are expected to expand, driven by the increasing demand for efficient, reliable, and high-quality welding solutions.

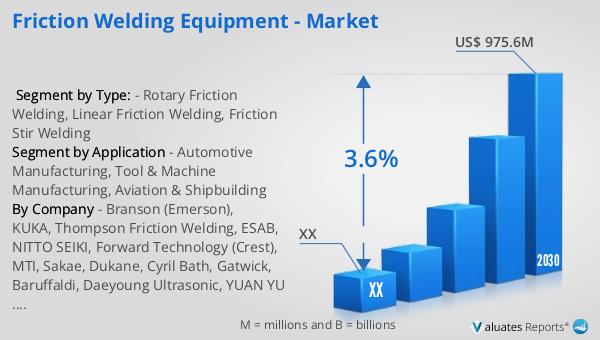

Friction Welding Equipment - Global Market Outlook:

The global market for friction welding equipment was valued at approximately $757.7 million in 2023, with projections indicating a growth to around $975.6 million by 2030. This growth is expected to occur at a compound annual growth rate (CAGR) of 3.6% from 2024 to 2030. Major players in this industry include prominent companies such as KUKA, Izumi Machine, Branson, Emerson, and ESAB. In 2018, the top three companies in the market collectively held a revenue market share exceeding 29%, highlighting their significant influence and competitive positioning within the industry. Regionally, Europe and North America have emerged as dominant forces in the friction welding equipment market, accounting for 41.93% and 33.54% of the market share, respectively. This regional dominance can be attributed to the strong presence of key industries such as automotive, aerospace, and manufacturing, which are major consumers of friction welding equipment. The market's growth is further supported by technological advancements and the increasing adoption of automation in manufacturing processes, which enhance the efficiency and precision of friction welding operations. As industries continue to seek innovative and reliable welding solutions, the global market for friction welding equipment is poised for sustained growth, driven by the demand for high-quality, efficient, and versatile welding technologies.

| Report Metric | Details |

| Report Name | Friction Welding Equipment - Market |

| Forecasted market size in 2030 | US$ 975.6 million |

| CAGR | 3.6% |

| Forecasted years | 2024 - 2030 |

| Segment by Type: |

|

| Segment by Application |

|

| By Region |

|

| By Company | Branson (Emerson), KUKA, Thompson Friction Welding, ESAB, NITTO SEIKI, Forward Technology (Crest), MTI, Sakae, Dukane, Cyril Bath, Gatwick, Baruffaldi, Daeyoung Ultrasonic, YUAN YU Industrial, Zhengchen, Changchun CNC Machine Tool, Longfei Welding Equipment, HWI, Yuyao City Biweekly, New Dimension Research, Bielomatik, Hornwell |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |