What is Expanded Polystyrene for Packaging - Global Market?

Expanded Polystyrene (EPS) for packaging is a versatile material widely used in the global market due to its lightweight, durable, and insulating properties. EPS is a type of plastic foam made from polystyrene beads, which are expanded and molded into various shapes and sizes. This material is particularly favored in the packaging industry because it provides excellent protection for goods during transportation and storage. Its cushioning properties help absorb shocks and impacts, making it ideal for fragile items. Additionally, EPS is resistant to moisture, which helps in preserving the quality of perishable goods. The global market for EPS packaging is driven by its cost-effectiveness and recyclability, making it an environmentally friendly option compared to other packaging materials. As industries continue to seek sustainable packaging solutions, the demand for EPS is expected to grow, supported by its adaptability across various sectors such as food and beverages, electronics, and healthcare. The material's ability to be molded into custom shapes also enhances its appeal, allowing businesses to create tailored packaging solutions that meet specific product requirements. Overall, EPS remains a critical component in the packaging industry, balancing functionality with environmental considerations.

Black, Grey, White in the Expanded Polystyrene for Packaging - Global Market:

When discussing Expanded Polystyrene (EPS) for packaging, the colors black, grey, and white play significant roles in the global market, each offering unique properties and applications. White EPS is the most common and widely used variant, known for its excellent insulation and lightweight characteristics. It is predominantly used in packaging applications where thermal insulation is crucial, such as in the food and beverage industry. White EPS is also favored for its clean appearance and ability to be easily molded into various shapes, making it suitable for a wide range of packaging needs. On the other hand, grey EPS is often enhanced with graphite particles, which improve its thermal insulation properties. This makes grey EPS an ideal choice for applications requiring superior insulation, such as in the construction industry for insulating panels and in packaging for temperature-sensitive products. The addition of graphite not only enhances its performance but also gives it a distinctive appearance that can be advantageous for branding purposes. Black EPS, while less common than its white and grey counterparts, is used in specific applications where UV resistance is important. The black color is achieved by adding carbon black, which provides UV stability and makes it suitable for outdoor applications or products exposed to sunlight. This variant is often used in the automotive industry and for packaging electronic components that require protection from UV degradation. Each color variant of EPS offers distinct advantages, allowing businesses to choose the most appropriate type based on their specific packaging requirements. The choice between black, grey, and white EPS often depends on factors such as the need for thermal insulation, UV resistance, and aesthetic considerations. As the global market for EPS packaging continues to evolve, the demand for these color variants is expected to grow, driven by their unique properties and the increasing emphasis on sustainable and efficient packaging solutions. The versatility of EPS in its various color forms ensures its continued relevance and adaptability in meeting the diverse needs of industries worldwide.

Food and Beverages, Foodservice, Healthcare, Electronics and Electrical Appliances, Building and Constructions, Others in the Expanded Polystyrene for Packaging - Global Market:

Expanded Polystyrene (EPS) for packaging finds extensive usage across various sectors, each benefiting from its unique properties. In the food and beverages industry, EPS is widely used for packaging perishable goods due to its excellent insulation properties. It helps maintain the temperature of food items, ensuring they remain fresh during transportation and storage. EPS packaging is commonly used for products like seafood, fruits, and vegetables, where temperature control is crucial. In the foodservice sector, EPS is used for disposable containers, cups, and trays, providing a lightweight and cost-effective solution for serving food and beverages. Its insulating properties also make it ideal for hot and cold drinks, keeping them at the desired temperature for longer periods. In the healthcare industry, EPS is used for packaging medical supplies and equipment, offering protection against physical damage and contamination. Its lightweight nature makes it easy to handle and transport, while its cushioning properties ensure the safe delivery of sensitive medical products. In the electronics and electrical appliances sector, EPS is used for packaging delicate components and devices, providing shock absorption and protection during shipping. Its ability to be molded into custom shapes allows for secure packaging of items with irregular shapes. In the building and construction industry, EPS is used for insulation panels and protective packaging for construction materials, offering thermal insulation and impact resistance. Other industries also benefit from EPS packaging, including automotive, where it is used for protective packaging of parts and components. The versatility and adaptability of EPS make it a preferred choice across these diverse sectors, providing reliable and efficient packaging solutions that meet specific industry needs.

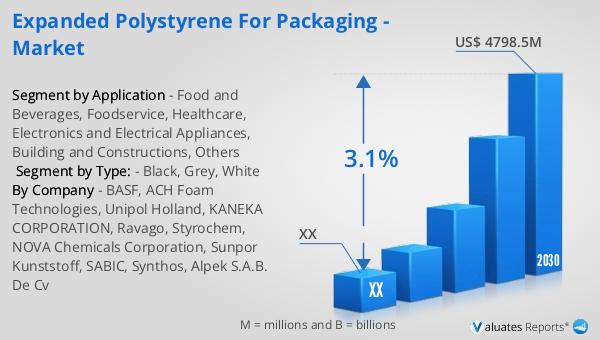

Expanded Polystyrene for Packaging - Global Market Outlook:

The global market for Expanded Polystyrene (EPS) for packaging was valued at approximately USD 3,857.8 million in 2023. It is projected to grow to a revised size of USD 4,798.5 million by 2030, reflecting a compound annual growth rate (CAGR) of 3.1% during the forecast period from 2024 to 2030. This growth is driven by the increasing demand for sustainable and efficient packaging solutions across various industries. Key players in the EPS packaging market include Schaumaplast, Atlas Roofing Corporation, Styrene Packaging & Insulation Ltd, PlastiFab, and Foamex, among others. These companies collectively hold a significant share of the market, with the top five players accounting for approximately 12% of the total market share. The competitive landscape of the EPS packaging market is characterized by innovation and the development of new products to meet the evolving needs of consumers. Companies are focusing on enhancing the performance and sustainability of EPS packaging, addressing environmental concerns while maintaining the material's inherent benefits. As industries continue to prioritize eco-friendly packaging solutions, the demand for EPS is expected to rise, supported by its recyclability and cost-effectiveness. The market outlook for EPS packaging remains positive, with opportunities for growth and expansion in various sectors.

| Report Metric | Details |

| Report Name | Expanded Polystyrene for Packaging - Market |

| Forecasted market size in 2030 | US$ 4798.5 million |

| CAGR | 3.1% |

| Forecasted years | 2024 - 2030 |

| Segment by Type: |

|

| Segment by Application |

|

| By Region |

|

| By Company | BASF, ACH Foam Technologies, Unipol Holland, KANEKA CORPORATION, Ravago, Styrochem, NOVA Chemicals Corporation, Sunpor Kunststoff, SABIC, Synthos, Alpek S.A.B. De Cv |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |