What is Dry Film PCB Photoresist - Global Market?

Dry Film PCB Photoresist is a crucial component in the manufacturing of printed circuit boards (PCBs), which are essential for a wide range of electronic devices. This material is used to create a protective layer on the PCB, allowing for precise etching and patterning of the circuit paths. The global market for Dry Film PCB Photoresist is driven by the increasing demand for electronic devices, which in turn fuels the need for more efficient and reliable PCBs. As technology advances, the complexity and miniaturization of electronic components require more sophisticated PCB designs, further boosting the demand for high-quality photoresist materials. The market is characterized by continuous innovation, with manufacturers striving to develop photoresists that offer better resolution, higher sensitivity, and improved environmental performance. The growth of the electronics industry, particularly in emerging markets, is a significant factor contributing to the expansion of the Dry Film PCB Photoresist market. Additionally, the push towards more sustainable and eco-friendly manufacturing processes is encouraging the development of photoresists with reduced environmental impact. Overall, the Dry Film PCB Photoresist market is poised for steady growth as it adapts to the evolving needs of the electronics industry.

Positive, Negative in the Dry Film PCB Photoresist - Global Market:

In the realm of Dry Film PCB Photoresist, the terms "positive" and "negative" refer to the types of photoresist materials used in the PCB manufacturing process. Positive photoresists are designed to become soluble when exposed to light, allowing the exposed areas to be washed away during development. This type of photoresist is favored for its ability to produce fine lines and intricate patterns, making it ideal for high-density and complex PCB designs. The global market for positive Dry Film PCB Photoresist is driven by the demand for advanced electronic devices that require precise and reliable circuit patterns. As electronic devices become more compact and feature-rich, the need for high-resolution PCBs increases, boosting the demand for positive photoresists. On the other hand, negative photoresists work in the opposite manner; they become insoluble when exposed to light, meaning the unexposed areas are removed during development. Negative photoresists are often used for applications where thicker photoresist layers are required, such as in the production of multilayer PCBs. The global market for negative Dry Film PCB Photoresist is supported by the growing demand for durable and robust PCBs that can withstand harsh operating conditions. Both positive and negative photoresists have their unique advantages and are chosen based on the specific requirements of the PCB design and manufacturing process. The choice between positive and negative photoresists is influenced by factors such as the desired resolution, the complexity of the circuit pattern, and the intended application of the PCB. As the electronics industry continues to evolve, the demand for both types of photoresists is expected to grow, driven by the need for more sophisticated and reliable electronic devices. The global market for Dry Film PCB Photoresist is characterized by a diverse range of applications, from consumer electronics to industrial and automotive sectors. Each application has its specific requirements, influencing the choice of photoresist type and formulation. In the consumer electronics sector, the demand for high-performance and miniaturized devices drives the need for positive photoresists that can deliver fine lines and high-resolution patterns. In contrast, the automotive and industrial sectors often require PCBs with thicker and more durable photoresist layers, making negative photoresists a preferred choice. The global market for Dry Film PCB Photoresist is also influenced by regional trends and technological advancements. In regions with a strong electronics manufacturing base, such as Asia-Pacific, the demand for both positive and negative photoresists is particularly high. The continuous innovation in photoresist technology, aimed at improving performance and reducing environmental impact, is a key factor driving the growth of the market. As manufacturers strive to meet the evolving needs of the electronics industry, the global market for Dry Film PCB Photoresist is expected to witness steady growth, supported by the increasing demand for advanced and reliable PCBs.

Automotive, Home Appliances, Electronics, Other in the Dry Film PCB Photoresist - Global Market:

The usage of Dry Film PCB Photoresist spans across various industries, including automotive, home appliances, electronics, and others, each with its unique requirements and applications. In the automotive industry, PCBs are used in a wide range of applications, from engine control units to infotainment systems and advanced driver-assistance systems (ADAS). The demand for reliable and durable PCBs in the automotive sector drives the need for high-quality Dry Film PCB Photoresist that can withstand harsh operating conditions, such as extreme temperatures and vibrations. The use of photoresists in automotive PCBs ensures precise circuit patterns and robust performance, contributing to the overall reliability and safety of automotive electronic systems. In the home appliances sector, PCBs are used in various devices, including washing machines, refrigerators, and air conditioners. The demand for energy-efficient and smart home appliances is driving the need for advanced PCBs with complex circuit patterns, which in turn fuels the demand for high-performance Dry Film PCB Photoresist. The use of photoresists in home appliance PCBs ensures accurate and reliable circuit patterns, enabling the development of innovative and energy-efficient devices. In the electronics industry, PCBs are a fundamental component of a wide range of devices, from smartphones and tablets to computers and wearable technology. The demand for miniaturized and high-performance electronic devices drives the need for advanced PCBs with fine lines and high-resolution patterns, which are made possible by the use of positive Dry Film PCB Photoresist. The use of photoresists in electronics PCBs ensures precise and reliable circuit patterns, enabling the development of compact and feature-rich devices. In addition to these industries, Dry Film PCB Photoresist is also used in other sectors, such as telecommunications, aerospace, and medical devices. Each of these sectors has its specific requirements, influencing the choice of photoresist type and formulation. The global market for Dry Film PCB Photoresist is characterized by a diverse range of applications, each with its unique challenges and opportunities. As technology continues to advance, the demand for high-quality and reliable PCBs is expected to grow, driving the need for innovative and high-performance Dry Film PCB Photoresist. The continuous innovation in photoresist technology, aimed at improving performance and reducing environmental impact, is a key factor driving the growth of the market. As manufacturers strive to meet the evolving needs of various industries, the global market for Dry Film PCB Photoresist is expected to witness steady growth, supported by the increasing demand for advanced and reliable PCBs.

Dry Film PCB Photoresist - Global Market Outlook:

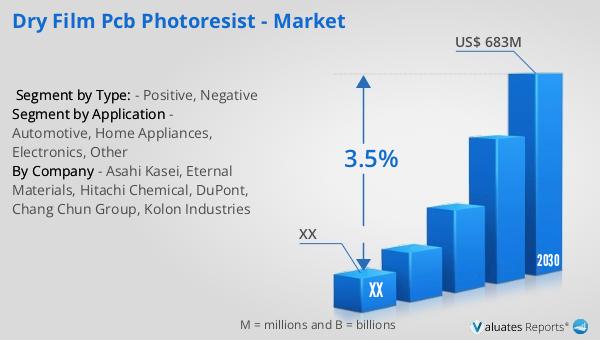

In 2023, the global market for Dry Film PCB Photoresist was valued at approximately $538.7 million. Looking ahead, projections indicate that by 2030, this market is expected to grow to a revised size of $683 million. This growth trajectory represents a compound annual growth rate (CAGR) of 3.5% over the forecast period from 2024 to 2030. This steady growth is indicative of the increasing demand for Dry Film PCB Photoresist across various industries, driven by the need for more sophisticated and reliable PCBs. The market's expansion is fueled by the continuous advancements in technology and the growing demand for electronic devices, which require high-quality photoresist materials for efficient and precise PCB manufacturing. As the electronics industry continues to evolve, the demand for Dry Film PCB Photoresist is expected to rise, supported by the need for advanced and reliable PCBs in various applications. The market's growth is also influenced by regional trends and technological advancements, with regions such as Asia-Pacific experiencing particularly high demand due to their strong electronics manufacturing base. Overall, the global market for Dry Film PCB Photoresist is poised for steady growth, driven by the increasing demand for advanced and reliable PCBs across various industries.

| Report Metric | Details |

| Report Name | Dry Film PCB Photoresist - Market |

| Forecasted market size in 2030 | US$ 683 million |

| CAGR | 3.5% |

| Forecasted years | 2024 - 2030 |

| Segment by Type: |

|

| Segment by Application |

|

| By Region |

|

| By Company | Asahi Kasei, Eternal Materials, Hitachi Chemical, DuPont, Chang Chun Group, Kolon Industries |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |