What is Coordinate Measuring Machine Probes - Global Market?

Coordinate Measuring Machine (CMM) Probes are essential tools in the field of precision measurement and quality control. These devices are used to measure the physical geometrical characteristics of an object, ensuring that it meets the required specifications and standards. The global market for CMM probes is a dynamic and evolving sector, driven by the increasing demand for high-precision manufacturing across various industries. These probes are integral to the operation of CMMs, which are used to inspect the dimensions of manufactured components, ensuring they adhere to strict tolerances. The market is characterized by a variety of probe types, each designed to meet specific measurement needs, including touch-trigger probes, scanning probes, and optical probes. As industries such as automotive, aerospace, and electronics continue to advance, the demand for accurate and reliable measurement tools like CMM probes is expected to grow. This growth is further fueled by technological advancements that enhance the capabilities and efficiency of these probes, making them indispensable in modern manufacturing processes. The global market for CMM probes is poised for significant expansion, reflecting the broader trends in industrial automation and quality assurance.

Touch-Trigger Probes, Discrete Point Probes, Others in the Coordinate Measuring Machine Probes - Global Market:

Touch-trigger probes, discrete point probes, and other types of probes play a crucial role in the global market for Coordinate Measuring Machine (CMM) probes. Touch-trigger probes are among the most commonly used types in CMM applications. They operate by physically contacting the surface of the object being measured, triggering a signal that records the precise location of the point of contact. This type of probe is highly valued for its accuracy and reliability, making it ideal for applications where precise measurements are critical. Touch-trigger probes are often used in industries such as automotive and aerospace, where the precision of components can significantly impact performance and safety. Discrete point probes, on the other hand, are designed to measure individual points on a surface. These probes are particularly useful in applications where specific points need to be measured with high accuracy, such as in the inspection of complex geometries or intricate components. Discrete point probes are often used in conjunction with other types of probes to provide a comprehensive measurement solution. In addition to touch-trigger and discrete point probes, there are other types of probes available in the market, each designed to meet specific measurement needs. For example, scanning probes are used to capture continuous data along a surface, providing a detailed profile of the object's geometry. Optical probes, which use light to measure dimensions, are ideal for non-contact applications where the object being measured is delicate or sensitive. The choice of probe type depends on the specific requirements of the measurement task, including the material of the object, the level of precision required, and the complexity of the geometry. As the global market for CMM probes continues to evolve, manufacturers are developing new and innovative probe technologies to meet the changing needs of industries. These advancements are driven by the increasing demand for high-precision measurement solutions in sectors such as automotive, aerospace, and electronics. The development of more advanced probe technologies is expected to enhance the capabilities of CMMs, enabling them to perform more complex and accurate measurements. This, in turn, will drive the growth of the global market for CMM probes, as industries continue to seek out reliable and efficient measurement solutions to ensure the quality and performance of their products.

Automotive Industry, Electronics Industry, Aerospace and Defense, Others in the Coordinate Measuring Machine Probes - Global Market:

The usage of Coordinate Measuring Machine (CMM) probes in various industries highlights their importance in ensuring precision and quality. In the automotive industry, CMM probes are indispensable for inspecting components such as engine parts, transmission systems, and body panels. The precision offered by these probes ensures that each part meets the stringent specifications required for optimal vehicle performance and safety. As automotive manufacturers strive to produce more efficient and reliable vehicles, the demand for accurate measurement tools like CMM probes continues to grow. In the electronics industry, CMM probes are used to measure the dimensions of intricate components such as circuit boards and semiconductor devices. The miniaturization of electronic components requires highly precise measurement tools to ensure that each part fits perfectly within the assembly. CMM probes provide the accuracy needed to inspect these tiny components, ensuring that they meet the required specifications and function correctly. In the aerospace and defense sectors, the use of CMM probes is critical for maintaining the safety and performance of aircraft and defense systems. These industries require components that adhere to the highest standards of precision and reliability, as even the smallest deviation can have significant consequences. CMM probes are used to inspect a wide range of components, from turbine blades to fuselage panels, ensuring that each part meets the necessary specifications. The ability to perform accurate and reliable measurements is essential for maintaining the safety and performance of aerospace and defense systems. Beyond these industries, CMM probes are also used in other sectors such as medical device manufacturing, where precision is crucial for ensuring the safety and effectiveness of medical equipment. The versatility and accuracy of CMM probes make them an essential tool in any industry where precision measurement is required. As industries continue to advance and the demand for high-quality products grows, the usage of CMM probes is expected to increase, driving the growth of the global market for these essential measurement tools.

Coordinate Measuring Machine Probes - Global Market Outlook:

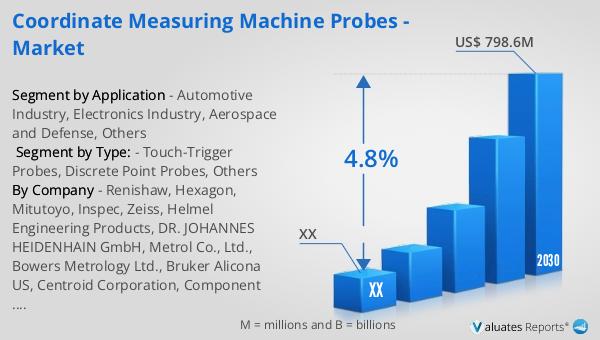

The global market for Coordinate Measuring Machine (CMM) probes was valued at approximately $566.8 million in 2023. This market is projected to grow significantly, reaching an estimated value of $798.6 million by 2030. This growth represents a compound annual growth rate (CAGR) of 4.8% during the forecast period from 2024 to 2030. The increasing demand for precision measurement tools across various industries is a key driver of this market growth. As industries such as automotive, aerospace, and electronics continue to advance, the need for accurate and reliable measurement solutions becomes more critical. CMM probes, with their ability to provide precise measurements, are essential tools in ensuring the quality and performance of manufactured components. The market's expansion is also fueled by technological advancements that enhance the capabilities of CMM probes, making them more efficient and versatile. As manufacturers continue to develop new and innovative probe technologies, the global market for CMM probes is expected to experience sustained growth. This growth reflects the broader trends in industrial automation and quality assurance, as industries seek out reliable and efficient measurement solutions to meet the demands of modern manufacturing processes.

| Report Metric | Details |

| Report Name | Coordinate Measuring Machine Probes - Market |

| Forecasted market size in 2030 | US$ 798.6 million |

| CAGR | 4.8% |

| Forecasted years | 2024 - 2030 |

| Segment by Type: |

|

| Segment by Application |

|

| By Region |

|

| By Company | Renishaw, Hexagon, Mitutoyo, Inspec, Zeiss, Helmel Engineering Products, DR. JOHANNES HEIDENHAIN GmbH, Metrol Co., Ltd., Bowers Metrology Ltd., Bruker Alicona US, Centroid Corporation, Component Engineering, DataPixel, DEA, A Brand Of Hexagon Metrology, Dr. Wolf & Beck GmbH, EverBeing International Corp., HEIDENHAIN CORPORATION, Hybrid Manufacturing Technologies, Laser Design, Inc., M&H Inprocess USA, Inc., MetrologyWorks Inc., Micro-Vu Corporation, Omex Technologies, Inc., Q-Mark Manufacturing, Inc., Sylvac SA, Tschorn GmbH, Wenzel Group GmbH & Co. KG, Xi`An Lead Metrology Co, Ltd. |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |