What is C5 & C9 Copolymerized Petroleum Resin - Global Market?

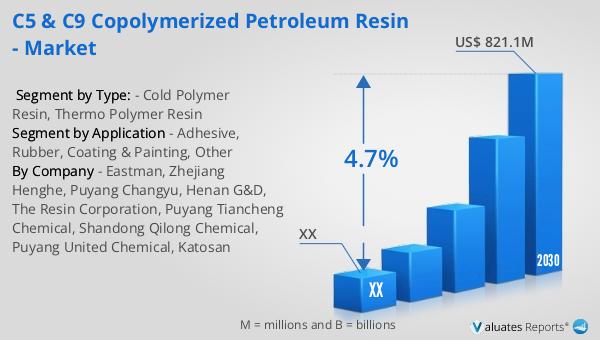

C5 and C9 copolymerized petroleum resins are specialized materials derived from the polymerization of C5 and C9 hydrocarbons, which are by-products of the cracking process in petroleum refining. These resins are known for their excellent adhesive properties, making them highly valuable in various industrial applications. The global market for C5 and C9 copolymerized petroleum resin was valued at approximately US$ 598 million in 2023. This market is projected to grow steadily, reaching an estimated size of US$ 821.1 million by 2030, with a compound annual growth rate (CAGR) of 4.7% during the forecast period from 2024 to 2030. These resins are particularly popular in the adhesive industry due to their ability to enhance tackiness and improve the performance of adhesives. Additionally, they find applications in rubber compounding, coatings, and paints, where they contribute to improved elasticity, durability, and gloss. The North American market for these resins is also significant, although specific valuation figures for 2023 and projections for 2030 are not provided. Overall, the demand for C5 and C9 copolymerized petroleum resins is driven by their versatile applications and the growing need for high-performance materials in various industries.

Cold Polymer Resin, Thermo Polymer Resin in the C5 & C9 Copolymerized Petroleum Resin - Global Market:

Cold polymer resin and thermo polymer resin are two distinct types of resins derived from C5 and C9 copolymerized petroleum resins, each with unique properties and applications. Cold polymer resin is typically produced at lower temperatures, which allows for the preservation of certain volatile components that contribute to its adhesive properties. This type of resin is particularly useful in applications where a strong initial tack is required, such as in pressure-sensitive adhesives used in tapes and labels. The cold polymerization process helps maintain the resin's flexibility and enhances its ability to bond with various substrates, making it ideal for use in the packaging and automotive industries. On the other hand, thermo polymer resin is produced at higher temperatures, resulting in a more stable and durable product. This type of resin is often used in applications where heat resistance and long-term stability are crucial, such as in hot-melt adhesives and sealants. The thermo polymerization process enhances the resin's thermal stability and resistance to oxidation, making it suitable for use in harsh environmental conditions. Both cold polymer and thermo polymer resins derived from C5 and C9 copolymerized petroleum resins are essential components in the global market, catering to diverse industrial needs. The versatility of these resins allows them to be tailored to specific applications, providing manufacturers with the flexibility to choose the most suitable resin type for their products. As industries continue to evolve and demand more advanced materials, the market for cold polymer and thermo polymer resins is expected to grow, driven by their unique properties and wide range of applications.

Adhesive, Rubber, Coating & Painting, Other in the C5 & C9 Copolymerized Petroleum Resin - Global Market:

C5 and C9 copolymerized petroleum resins play a crucial role in various industries, particularly in adhesives, rubber, coatings, and paints. In the adhesive industry, these resins are valued for their ability to enhance the tackiness and bonding strength of adhesives. They are commonly used in pressure-sensitive adhesives, hot-melt adhesives, and contact adhesives, where they improve the adhesive's performance by providing better initial tack and long-lasting adhesion. The rubber industry also benefits from the use of C5 and C9 copolymerized petroleum resins, as they improve the elasticity and durability of rubber products. These resins are often used in the production of tires, rubber bands, and other rubber-based products, where they enhance the material's resistance to wear and tear. In the coatings and paints industry, C5 and C9 copolymerized petroleum resins are used to improve the gloss, hardness, and adhesion of coatings. They are commonly used in automotive coatings, industrial paints, and varnishes, where they provide a smooth and durable finish. Additionally, these resins are used in other applications such as printing inks, where they improve the ink's adhesion to various substrates and enhance its color intensity. The versatility of C5 and C9 copolymerized petroleum resins makes them indispensable in these industries, as they offer a range of benefits that improve the performance and quality of the final products. As the demand for high-performance materials continues to grow, the market for C5 and C9 copolymerized petroleum resins is expected to expand, driven by their wide range of applications and unique properties.

C5 & C9 Copolymerized Petroleum Resin - Global Market Outlook:

The global market for C5 and C9 copolymerized petroleum resin was valued at approximately US$ 598 million in 2023, with expectations to grow to US$ 821.1 million by 2030, reflecting a compound annual growth rate (CAGR) of 4.7% from 2024 to 2030. This growth is indicative of the increasing demand for these resins across various industries due to their versatile applications and unique properties. In North America, the market for C5 and C9 copolymerized petroleum resin is also significant, although specific valuation figures for 2023 and projections for 2030 are not provided. The steady growth in this region can be attributed to the robust industrial base and the continuous demand for high-performance materials in sectors such as automotive, packaging, and construction. The increasing focus on sustainability and the development of eco-friendly products are also driving the demand for C5 and C9 copolymerized petroleum resins, as they offer a balance between performance and environmental impact. As industries continue to evolve and seek innovative solutions, the market for C5 and C9 copolymerized petroleum resins is poised for growth, supported by their ability to meet the diverse needs of various applications.

| Report Metric | Details |

| Report Name | C5 & C9 Copolymerized Petroleum Resin - Market |

| Forecasted market size in 2030 | US$ 821.1 million |

| CAGR | 4.7% |

| Forecasted years | 2024 - 2030 |

| Segment by Type: |

|

| Segment by Application |

|

| By Region |

|

| By Company | Eastman, Zhejiang Henghe, Puyang Changyu, Henan G&D, The Resin Corporation, Puyang Tiancheng Chemical, Shandong Qilong Chemical, Puyang United Chemical, Katosan |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |