What is Auxiliary Fuel Tanks - Global Market?

Auxiliary fuel tanks are additional fuel storage units that are installed in vehicles to extend their range by holding extra fuel. These tanks are particularly useful for long-distance travel, off-road adventures, or in areas where fuel stations are sparse. The global market for auxiliary fuel tanks is driven by the increasing demand for vehicles with extended range capabilities. As more people embark on long road trips or operate vehicles in remote areas, the need for additional fuel storage becomes apparent. These tanks are designed to be compatible with various types of vehicles, including passenger cars, commercial vehicles, and even aircraft. They come in different sizes and materials, such as plastic and aluminum alloy, to cater to diverse consumer needs. The market is also influenced by advancements in technology that make these tanks more efficient and safer to use. With the growing emphasis on fuel efficiency and the need to reduce emissions, auxiliary fuel tanks are becoming an essential component for many vehicle owners. As the automotive industry continues to evolve, the demand for auxiliary fuel tanks is expected to rise, making it a significant segment in the global automotive market.

Plastic, Aluminum Alloy in the Auxiliary Fuel Tanks - Global Market:

Plastic and aluminum alloy are two of the most common materials used in the manufacturing of auxiliary fuel tanks. Each material offers distinct advantages and disadvantages, making them suitable for different applications and consumer preferences. Plastic auxiliary fuel tanks are popular due to their lightweight nature, which contributes to better fuel efficiency by reducing the overall weight of the vehicle. They are also resistant to corrosion, which is a significant advantage in environments where moisture and other corrosive elements are present. Plastic tanks are often more affordable than their metal counterparts, making them an attractive option for budget-conscious consumers. However, they may not be as durable as metal tanks, especially in extreme conditions or when exposed to high temperatures. On the other hand, aluminum alloy auxiliary fuel tanks are known for their strength and durability. Aluminum is a lightweight metal, which helps in maintaining the vehicle's fuel efficiency while providing a robust and long-lasting fuel storage solution. These tanks are highly resistant to corrosion, making them ideal for use in harsh environments. Aluminum alloy tanks are also capable of withstanding higher temperatures compared to plastic tanks, which can be crucial in certain applications. However, the cost of aluminum tanks is generally higher than plastic tanks, which can be a consideration for some consumers. Additionally, the manufacturing process for aluminum tanks can be more complex, potentially leading to longer production times. The choice between plastic and aluminum alloy auxiliary fuel tanks often depends on the specific needs and preferences of the consumer. For those who prioritize cost and weight, plastic tanks may be the preferred option. They are suitable for everyday use and can provide adequate fuel storage for most applications. However, for consumers who require a more durable and temperature-resistant solution, aluminum alloy tanks may be the better choice. These tanks are often favored by those who operate vehicles in extreme conditions or who need a long-lasting fuel storage solution. In the global market, the demand for both plastic and aluminum alloy auxiliary fuel tanks is influenced by various factors, including advancements in material technology, environmental regulations, and consumer preferences. As manufacturers continue to innovate and improve the performance of these tanks, the market is likely to see a shift in consumer preferences towards more efficient and environmentally friendly options. The ongoing development of new materials and manufacturing techniques is expected to further enhance the performance and appeal of both plastic and aluminum alloy auxiliary fuel tanks, making them an integral part of the automotive industry.

Passenger Cars, Commercial Vehicles in the Auxiliary Fuel Tanks - Global Market:

Auxiliary fuel tanks play a crucial role in extending the range and versatility of both passenger cars and commercial vehicles. In passenger cars, these tanks are often used by individuals who frequently travel long distances or who live in areas with limited access to fuel stations. By providing additional fuel storage, auxiliary tanks allow drivers to travel further without the need for frequent refueling stops. This is particularly beneficial for road trips, where access to fuel stations may be limited, or in rural areas where fuel availability can be sporadic. The convenience of having extra fuel on hand can also provide peace of mind to drivers, knowing that they have a backup supply in case of emergencies. In commercial vehicles, auxiliary fuel tanks are essential for businesses that rely on transportation for their operations. These tanks enable trucks, vans, and other commercial vehicles to cover longer distances without the need for frequent refueling, which can be time-consuming and costly. For industries such as logistics, construction, and agriculture, where vehicles often operate in remote locations or need to travel long distances, auxiliary fuel tanks can significantly enhance operational efficiency. By reducing the need for frequent stops, businesses can save time and money, ultimately improving their bottom line. The use of auxiliary fuel tanks in commercial vehicles also supports the growing demand for fuel-efficient and environmentally friendly transportation solutions. By allowing vehicles to carry more fuel, these tanks can help reduce the number of trips needed to refuel, thereby decreasing overall fuel consumption and emissions. This is particularly important in today's market, where there is increasing pressure on businesses to adopt sustainable practices and reduce their carbon footprint. Auxiliary fuel tanks can be a valuable tool in achieving these goals, providing a practical solution for businesses looking to improve their environmental impact. Overall, the global market for auxiliary fuel tanks in passenger cars and commercial vehicles is driven by the need for extended range, operational efficiency, and environmental sustainability. As more consumers and businesses recognize the benefits of these tanks, their adoption is expected to increase, making them an essential component of modern transportation. With ongoing advancements in technology and materials, auxiliary fuel tanks are likely to become even more efficient and versatile, further enhancing their appeal to a wide range of consumers and industries.

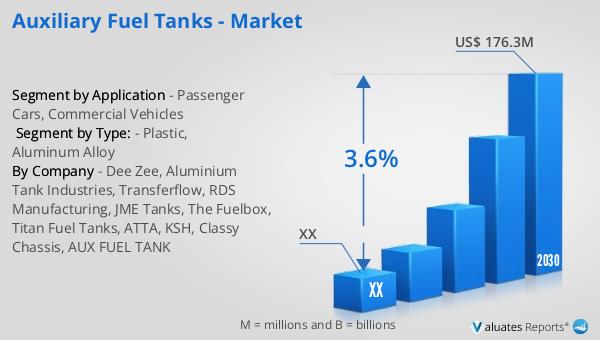

Auxiliary Fuel Tanks - Global Market Outlook:

The global market for auxiliary fuel tanks was valued at approximately $139.3 million in 2023. It is projected to grow to a revised size of $176.3 million by 2030, with a compound annual growth rate (CAGR) of 3.6% during the forecast period from 2024 to 2030. Currently, over 90% of the world's automobiles are concentrated in three major continents: Asia, Europe, and North America. Among these, Asia leads in automobile production, accounting for 56% of the global output. Europe follows with 20%, and North America contributes 16%. This concentration of automobile production in these regions significantly influences the demand for auxiliary fuel tanks, as manufacturers and consumers alike seek to enhance vehicle range and efficiency. The growth in the auxiliary fuel tank market is closely tied to the automotive industry's expansion in these key regions. As the demand for vehicles with extended range capabilities continues to rise, the auxiliary fuel tank market is poised for steady growth. This trend reflects the broader shift towards more efficient and sustainable transportation solutions, as consumers and manufacturers alike prioritize fuel efficiency and reduced emissions.

| Report Metric | Details |

| Report Name | Auxiliary Fuel Tanks - Market |

| Forecasted market size in 2030 | US$ 176.3 million |

| CAGR | 3.6% |

| Forecasted years | 2024 - 2030 |

| Segment by Type: |

|

| Segment by Application |

|

| By Region |

|

| By Company | Dee Zee, Aluminium Tank Industries, Transferflow, RDS Manufacturing, JME Tanks, The Fuelbox, Titan Fuel Tanks, ATTA, KSH, Classy Chassis, AUX FUEL TANK |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |