What is Automatic Induction Cap Sealing Machine - Global Market?

Automatic induction cap sealing machines are specialized equipment used in various industries to seal containers with induction heat. This process involves using electromagnetic induction to generate heat, which melts a foil liner inside the cap, creating a hermetic seal on the container. This technology is crucial for ensuring product integrity, preventing leaks, and extending shelf life. The global market for these machines is expanding due to increasing demand for efficient packaging solutions across industries such as food and beverage, pharmaceuticals, and cosmetics. The machines are valued for their ability to provide tamper-evident seals, which are essential for consumer safety and regulatory compliance. As industries continue to prioritize product safety and quality, the adoption of automatic induction cap sealing machines is expected to grow, driven by advancements in technology and the need for high-speed, reliable sealing solutions. The market is characterized by a range of machines, from fully automated systems to semi-automated ones, catering to different production scales and operational needs.

Full-automatic Induction Cap Sealing Machine, Semi-automatic Induction Cap Sealing Machine in the Automatic Induction Cap Sealing Machine - Global Market:

The global market for automatic induction cap sealing machines is diverse, encompassing both full-automatic and semi-automatic systems. Full-automatic induction cap sealing machines are designed for high-volume production environments where speed and efficiency are paramount. These machines are integrated into production lines, automatically handling the sealing process without the need for manual intervention. They are equipped with advanced features such as conveyor systems, automatic cap feeding, and precise control mechanisms to ensure consistent sealing quality. Full-automatic machines are ideal for large-scale manufacturers in industries like food and beverage, pharmaceuticals, and cosmetics, where high throughput and minimal downtime are critical. On the other hand, semi-automatic induction cap sealing machines offer a more flexible solution for smaller production runs or businesses with limited space and budget. These machines require some level of manual operation, such as placing the cap on the container or positioning the container under the sealing head. Despite this, they still provide reliable sealing performance and are suitable for small to medium-sized enterprises or niche product lines. Semi-automatic machines are often favored by companies that need to balance cost with operational efficiency, offering a practical solution for businesses that do not require the high-speed capabilities of fully automated systems. Both types of machines play a vital role in the global market, catering to the diverse needs of manufacturers seeking to enhance their packaging processes. As technology continues to evolve, these machines are becoming more sophisticated, with features such as digital controls, energy-efficient designs, and enhanced safety mechanisms. This evolution is driven by the increasing demand for sustainable packaging solutions and the need to comply with stringent industry regulations. The choice between full-automatic and semi-automatic machines depends on various factors, including production volume, budget, and specific industry requirements. Manufacturers must carefully assess their operational needs and future growth plans to select the most suitable machine for their production line. The global market for automatic induction cap sealing machines is poised for growth, supported by the ongoing advancements in technology and the rising demand for efficient, reliable packaging solutions across multiple industries.

Food and Beverage Industry, Cosmetics and Personal Care Industry, Pharmaceutical Industry, Others in the Automatic Induction Cap Sealing Machine - Global Market:

Automatic induction cap sealing machines are widely used across various industries, each with specific requirements and benefits. In the food and beverage industry, these machines are essential for ensuring product safety and extending shelf life. They provide a tamper-evident seal that protects against contamination and preserves the freshness of products such as juices, sauces, and dairy items. The ability to maintain product integrity is crucial in this industry, where consumer trust and regulatory compliance are paramount. In the cosmetics and personal care industry, induction cap sealing machines are used to secure products like lotions, shampoos, and creams. The machines ensure that the packaging is leak-proof and tamper-evident, which is vital for maintaining the quality and safety of these products. The aesthetic appeal of the packaging is also important in this industry, and induction sealing provides a clean, professional finish that enhances brand image. The pharmaceutical industry relies heavily on induction cap sealing machines to ensure the safety and efficacy of medications. These machines provide a hermetic seal that prevents contamination and ensures the integrity of the product throughout its shelf life. This is particularly important for liquid medications and other sensitive products that require airtight packaging. The use of induction sealing in the pharmaceutical industry is driven by stringent regulatory requirements and the need to protect consumer health. Beyond these primary industries, automatic induction cap sealing machines are also used in other sectors such as chemicals, automotive, and household products. In these industries, the machines provide a reliable sealing solution that prevents leaks and ensures product safety during transportation and storage. The versatility of induction cap sealing machines makes them an invaluable tool for manufacturers seeking to enhance their packaging processes and meet the diverse needs of their customers. As the global market for these machines continues to grow, their usage across various industries is expected to expand, driven by the increasing demand for efficient, reliable packaging solutions.

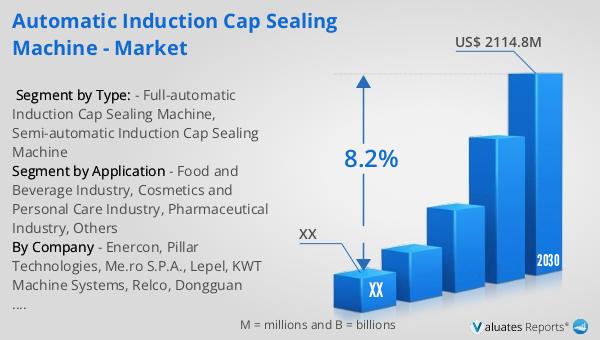

Automatic Induction Cap Sealing Machine - Global Market Outlook:

The global market for automatic induction cap sealing machines was valued at approximately $1,247 million in 2023. It is projected to grow significantly, reaching an estimated $2,114.8 million by 2030, with a compound annual growth rate (CAGR) of 8.2% during the forecast period from 2024 to 2030. This growth is indicative of the increasing demand for advanced packaging solutions across various industries. The packaging industry is inherently technology-driven, with continuous advancements aimed at improving efficiency, safety, and sustainability. Automatic induction cap sealing machines are at the forefront of this technological evolution, offering manufacturers a reliable and efficient means of sealing containers. The market's expansion is fueled by the growing need for tamper-evident and leak-proof packaging, which is essential for maintaining product integrity and consumer trust. As industries such as food and beverage, pharmaceuticals, and cosmetics continue to prioritize product safety and quality, the adoption of these machines is expected to rise. The market outlook reflects a positive trajectory, driven by technological advancements and the increasing emphasis on sustainable packaging solutions. Manufacturers are investing in research and development to enhance the capabilities of these machines, ensuring they meet the evolving needs of the global market. The future of the automatic induction cap sealing machine market looks promising, with opportunities for growth and innovation across various sectors.

| Report Metric | Details |

| Report Name | Automatic Induction Cap Sealing Machine - Market |

| Forecasted market size in 2030 | US$ 2114.8 million |

| CAGR | 8.2% |

| Forecasted years | 2024 - 2030 |

| Segment by Type: |

|

| Segment by Application |

|

| By Region |

|

| By Company | Enercon, Pillar Technologies, Me.ro S.P.A., Lepel, KWT Machine Systems, Relco, Dongguan Sammi, Parle, Accutek, Proking, Nantong Hengli Packing Technology, AutoMate Technologies, APACKS, Kaps-All Packaging Systems |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |