What is Asphalt Milling Device - Global Market?

An asphalt milling device is a specialized piece of machinery used in the construction and maintenance of roads. It is designed to remove the top layer of asphalt from a road surface, allowing for the recycling of the material and the preparation of the surface for new asphalt. This process is essential for maintaining road quality and extending the lifespan of roadways. The global market for asphalt milling devices is driven by the increasing need for road maintenance and the growing emphasis on sustainable construction practices. These machines come in various sizes and configurations, catering to different project requirements, from small-scale urban road repairs to large highway resurfacing projects. The market is characterized by technological advancements that enhance the efficiency and precision of milling operations, as well as the development of eco-friendly models that reduce emissions and energy consumption. As urbanization and infrastructure development continue to rise globally, the demand for asphalt milling devices is expected to grow, making it a vital component of the construction equipment industry.

Wheeled Type, Tracked Type in the Asphalt Milling Device - Global Market:

Asphalt milling devices are primarily categorized into two types: wheeled and tracked. Each type has its unique features and advantages, making them suitable for different applications in the global market. Wheeled asphalt milling devices are known for their mobility and speed. They are equipped with rubber tires, which allow them to move quickly from one site to another, making them ideal for projects that require frequent relocation. These machines are generally lighter and more maneuverable, which is beneficial in urban areas with tight spaces and heavy traffic. The wheeled type is also easier to transport on public roads without causing significant damage to the pavement. However, they may not provide the same level of stability and traction as tracked machines, especially on uneven or loose surfaces. On the other hand, tracked asphalt milling devices are equipped with tracks instead of wheels, providing superior stability and traction. This makes them suitable for heavy-duty applications and challenging terrains, such as steep inclines or loose gravel. Tracked machines are often used in large-scale projects where precision and power are crucial, such as highway construction or major road rehabilitation. They can handle larger milling drums, allowing for deeper cuts and faster material removal. Despite their advantages, tracked machines are generally slower and less maneuverable than their wheeled counterparts, which can be a disadvantage in projects that require frequent movement. Additionally, the tracks can cause more damage to road surfaces during transportation, necessitating careful planning and logistics. Both wheeled and tracked asphalt milling devices are equipped with advanced features to enhance their performance and efficiency. These include automated control systems, which allow operators to adjust milling depth and speed with precision, and dust suppression systems, which minimize the environmental impact of milling operations. Manufacturers are also focusing on developing eco-friendly models that reduce fuel consumption and emissions, in response to growing environmental concerns. The choice between wheeled and tracked asphalt milling devices depends on various factors, including the nature of the project, the terrain, and the specific requirements of the job. Contractors must carefully evaluate these factors to select the most suitable machine for their needs. In conclusion, both wheeled and tracked asphalt milling devices play a crucial role in the global market, each offering distinct advantages that cater to different project requirements. As technology continues to advance, these machines are expected to become even more efficient and environmentally friendly, further driving their demand in the construction industry.

Road Construction, Bridge Engineering, Others in the Asphalt Milling Device - Global Market:

Asphalt milling devices are widely used in various areas, including road construction, bridge engineering, and other infrastructure projects. In road construction, these machines are essential for maintaining and upgrading road surfaces. They remove the damaged or worn-out top layer of asphalt, allowing for the recycling of the material and the application of a new layer. This process not only extends the lifespan of the road but also improves its safety and performance. Asphalt milling is particularly important in urban areas, where roads are subject to heavy traffic and frequent wear and tear. By ensuring smooth and even surfaces, milling devices help reduce vehicle damage and enhance driving comfort. In bridge engineering, asphalt milling devices are used to prepare bridge decks for resurfacing. Bridges are exposed to harsh environmental conditions and heavy loads, which can lead to surface deterioration over time. Milling machines remove the damaged asphalt layer, allowing for the inspection and repair of the underlying structure. This process is crucial for maintaining the integrity and safety of bridges, as well as extending their service life. Additionally, asphalt milling devices are used in other infrastructure projects, such as airport runways, parking lots, and industrial sites. In these applications, milling machines help maintain the quality and functionality of the surfaces, ensuring they can withstand heavy use and environmental stress. The versatility and efficiency of asphalt milling devices make them indispensable tools in the construction and maintenance of various infrastructure projects. As urbanization and infrastructure development continue to rise globally, the demand for these machines is expected to grow, further driving the global market for asphalt milling devices.

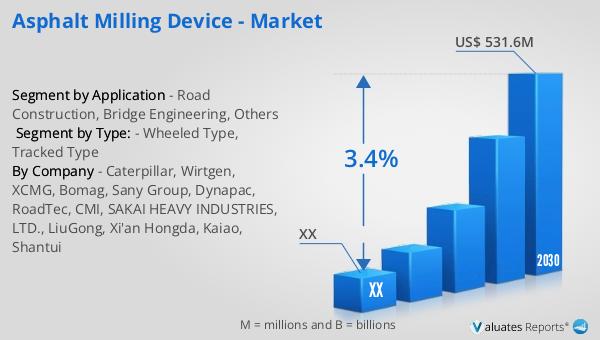

Asphalt Milling Device - Global Market Outlook:

The global market for asphalt milling devices was valued at approximately $421 million in 2023. It is projected to grow to a revised size of around $531.6 million by 2030, reflecting a compound annual growth rate (CAGR) of 3.4% during the forecast period from 2024 to 2030. This growth is driven by the increasing demand for road maintenance and infrastructure development worldwide. The North American market for asphalt milling devices also shows promising growth potential. Although specific figures for the North American market in 2023 and 2030 are not provided, it is expected to experience a steady CAGR during the forecast period. The growth in this region can be attributed to the ongoing infrastructure projects and the need for efficient road maintenance solutions. As governments and private sectors invest in upgrading and expanding transportation networks, the demand for asphalt milling devices is likely to increase. The market outlook for asphalt milling devices is positive, with technological advancements and environmental considerations playing a significant role in shaping the industry's future. Manufacturers are focusing on developing more efficient and eco-friendly machines to meet the evolving needs of the construction industry. As a result, the global market for asphalt milling devices is expected to continue its upward trajectory, driven by the growing emphasis on sustainable construction practices and the need for high-quality road infrastructure.

| Report Metric | Details |

| Report Name | Asphalt Milling Device - Market |

| Forecasted market size in 2030 | US$ 531.6 million |

| CAGR | 3.4% |

| Forecasted years | 2024 - 2030 |

| Segment by Type: |

|

| Segment by Application |

|

| By Region |

|

| By Company | Caterpillar, Wirtgen, XCMG, Bomag, Sany Group, Dynapac, RoadTec, CMI, SAKAI HEAVY INDUSTRIES, LTD., LiuGong, Xi'an Hongda, Kaiao, Shantui |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |