What is Aerospace Parts 3D Printer - Global Market?

The Aerospace Parts 3D Printer Global Market is a rapidly evolving sector that leverages advanced 3D printing technology to manufacture components for the aerospace industry. This market is driven by the increasing demand for lightweight, durable, and complex parts that traditional manufacturing methods struggle to produce efficiently. 3D printing, also known as additive manufacturing, allows for the creation of intricate designs with reduced material waste, which is crucial in aerospace applications where weight and material efficiency are paramount. The technology enables manufacturers to produce parts on-demand, reducing inventory costs and lead times. Additionally, 3D printing supports the customization of parts, which is particularly beneficial for specialized aerospace applications. As the aerospace industry continues to grow, the demand for innovative manufacturing solutions like 3D printing is expected to rise, making it a key area of focus for companies looking to enhance their production capabilities and maintain a competitive edge in the market. The global market for aerospace parts 3D printers is poised for significant growth as more companies adopt this technology to meet the evolving needs of the aerospace sector.

Aircraft, UAVs, Spacecraft in the Aerospace Parts 3D Printer - Global Market:

In the realm of aerospace, the use of 3D printing technology is transforming the production of parts for aircraft, Unmanned Aerial Vehicles (UAVs), and spacecraft. Aircraft manufacturers are increasingly adopting 3D printing to produce components that are lighter and more efficient, which can lead to significant fuel savings and reduced emissions. This is particularly important in the commercial aviation sector, where operational efficiency is a key competitive factor. For UAVs, which are often used in military and surveillance applications, 3D printing offers the ability to rapidly prototype and produce parts that meet specific mission requirements. The flexibility of 3D printing allows for the creation of complex geometries that can enhance the performance and capabilities of UAVs. In the context of spacecraft, 3D printing is revolutionizing the way parts are manufactured for space exploration. The ability to produce parts with high precision and reliability is crucial for spacecraft, where failure is not an option. 3D printing also enables the production of parts in space, which can significantly reduce the cost and complexity of space missions. As the aerospace industry continues to push the boundaries of what is possible, the role of 3D printing in the production of aircraft, UAVs, and spacecraft is expected to grow, offering new opportunities for innovation and efficiency.

OEM, MRO in the Aerospace Parts 3D Printer - Global Market:

The application of aerospace parts 3D printers in Original Equipment Manufacturing (OEM) and Maintenance, Repair, and Overhaul (MRO) sectors is reshaping the aerospace industry. In the OEM sector, 3D printing is being used to produce parts that are integral to the construction of new aircraft and spacecraft. The technology allows manufacturers to create parts with complex geometries that are difficult or impossible to achieve with traditional manufacturing methods. This capability is particularly valuable in the aerospace industry, where the performance and efficiency of components are critical. 3D printing also enables OEMs to reduce the weight of parts, which can lead to significant fuel savings and reduced emissions. In the MRO sector, 3D printing is being used to produce replacement parts on-demand, reducing the need for large inventories and long lead times. This is particularly beneficial for older aircraft, where parts may no longer be in production. The ability to produce parts quickly and efficiently can significantly reduce the downtime of aircraft, improving operational efficiency and reducing costs. As the aerospace industry continues to evolve, the use of 3D printing in OEM and MRO sectors is expected to increase, offering new opportunities for innovation and efficiency.

Aerospace Parts 3D Printer - Global Market Outlook:

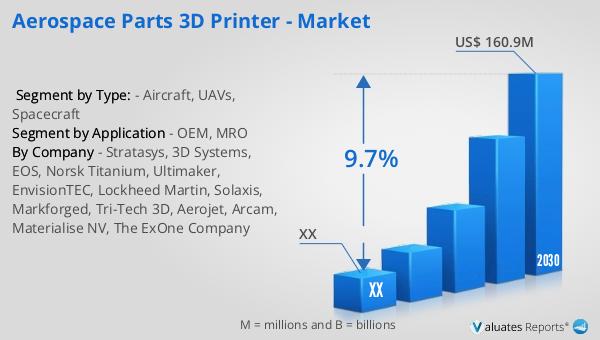

The global market for aerospace parts 3D printers was valued at approximately $87 million in 2023, with projections indicating a growth to around $160.9 million by 2030. This represents a compound annual growth rate (CAGR) of 9.7% over the forecast period from 2024 to 2030. The North American market, a significant player in this sector, was valued at an undisclosed amount in 2023, with expectations of reaching a higher value by 2030, maintaining a steady growth trajectory throughout the forecast period. This growth is driven by the increasing adoption of 3D printing technology in the aerospace industry, as companies seek to improve efficiency, reduce costs, and enhance the performance of their products. The ability to produce complex parts with reduced material waste and shorter lead times is a key factor driving the demand for aerospace parts 3D printers. As the technology continues to advance, the market is expected to expand, offering new opportunities for companies to innovate and compete in the global aerospace industry.

| Report Metric | Details |

| Report Name | Aerospace Parts 3D Printer - Market |

| Forecasted market size in 2030 | US$ 160.9 million |

| CAGR | 9.7% |

| Forecasted years | 2024 - 2030 |

| Segment by Type: |

|

| Segment by Application |

|

| By Region |

|

| By Company | Stratasys, 3D Systems, EOS, Norsk Titanium, Ultimaker, EnvisionTEC, Lockheed Martin, Solaxis, Markforged, Tri-Tech 3D, Aerojet, Arcam, Materialise NV, The ExOne Company |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |