What is Global PTOP for Rubber Tackifier Market?

The Global PTOP for Rubber Tackifier Market is a specialized segment within the broader chemical industry, focusing on the production and distribution of PTOP (p-tert-octylphenol) used as a tackifier in rubber manufacturing. Tackifiers are crucial additives that enhance the stickiness or tack of rubber compounds, making them essential in various industrial applications. PTOP, in particular, is valued for its ability to improve the performance characteristics of rubber, such as adhesion, flexibility, and durability. This market is driven by the increasing demand for high-performance rubber products across various sectors, including automotive, construction, and industrial manufacturing. The global market for PTOP in rubber tackifiers is characterized by a competitive landscape with numerous players striving to innovate and meet the evolving needs of end-users. As industries continue to seek materials that offer superior performance and sustainability, the demand for PTOP as a rubber tackifier is expected to grow, albeit at a moderate pace. The market's growth is also influenced by regulatory frameworks and environmental considerations, prompting manufacturers to explore eco-friendly alternatives and production methods. Overall, the Global PTOP for Rubber Tackifier Market plays a vital role in supporting the development of advanced rubber products that meet the stringent requirements of modern applications.

Purity≤98%, Purity>98% in the Global PTOP for Rubber Tackifier Market:

In the Global PTOP for Rubber Tackifier Market, the purity of PTOP is a critical factor that influences its performance and application. PTOP with a purity of ≤98% and PTOP with a purity of >98% are two distinct categories that cater to different needs within the industry. PTOP with a purity of ≤98% is typically used in applications where the highest level of performance is not the primary concern. This category is often more cost-effective and is suitable for general-purpose applications where the tackifier's role is to provide basic adhesion and flexibility. Industries that do not require the utmost precision in rubber performance may opt for this level of purity to balance cost and functionality. On the other hand, PTOP with a purity of >98% is preferred in applications that demand superior performance and reliability. This higher purity level ensures that the tackifier delivers optimal adhesion, elasticity, and durability, making it ideal for high-performance rubber products. Such applications are common in sectors where the rubber components are subjected to extreme conditions or where precision is critical, such as in automotive and aerospace industries. The choice between these two purity levels depends on the specific requirements of the application, cost considerations, and the desired performance characteristics of the final rubber product. Manufacturers often conduct thorough assessments to determine the most suitable purity level for their needs, taking into account factors such as environmental conditions, mechanical stress, and regulatory compliance. As the market evolves, there is a growing emphasis on developing PTOP with higher purity levels to meet the increasing demand for advanced rubber products. This trend is driven by the need for materials that can withstand more rigorous applications while also adhering to stricter environmental and safety standards. Consequently, research and development efforts are focused on refining production processes to achieve higher purity levels without compromising on cost-effectiveness. The distinction between PTOP with ≤98% purity and >98% purity highlights the importance of customization and precision in the rubber tackifier market. By offering different purity levels, manufacturers can cater to a wide range of applications, ensuring that each product meets the specific needs of its intended use. This flexibility is crucial in a market where performance requirements can vary significantly across different industries and applications. As industries continue to innovate and push the boundaries of what is possible with rubber materials, the demand for high-purity PTOP is expected to rise, driving further advancements in production techniques and quality control measures. Ultimately, the choice of PTOP purity level is a strategic decision that can significantly impact the performance and success of rubber products in the market.

Automotive, Construction, Industrial, Other in the Global PTOP for Rubber Tackifier Market:

The Global PTOP for Rubber Tackifier Market finds extensive usage across various sectors, including automotive, construction, industrial, and other applications. In the automotive industry, PTOP is used as a tackifier to enhance the performance of rubber components such as tires, seals, and gaskets. The improved adhesion and flexibility provided by PTOP ensure that these components can withstand the demanding conditions of automotive environments, including temperature fluctuations, mechanical stress, and exposure to chemicals. This makes PTOP an essential additive in the production of high-performance automotive rubber products that meet stringent safety and durability standards. In the construction sector, PTOP is utilized in the manufacturing of rubber-based materials used in building and infrastructure projects. These materials include roofing membranes, sealants, and adhesives, where the tackifier's role is to provide strong adhesion and resistance to environmental factors such as moisture, UV radiation, and temperature changes. The use of PTOP in construction applications ensures that rubber materials maintain their integrity and performance over time, contributing to the longevity and reliability of buildings and infrastructure. In industrial applications, PTOP is used in the production of rubber components that are integral to machinery and equipment. These components, such as belts, hoses, and gaskets, require high levels of adhesion and flexibility to function effectively in demanding industrial environments. PTOP enhances the performance of these components, ensuring that they can withstand mechanical stress, chemical exposure, and temperature variations. This makes PTOP a valuable additive in the production of industrial rubber products that are critical to the operation and efficiency of machinery and equipment. Beyond these primary sectors, PTOP is also used in other applications where rubber materials are required to perform under challenging conditions. This includes the production of consumer goods, medical devices, and sports equipment, where the tackifier's role is to enhance the performance and durability of rubber components. The versatility of PTOP as a rubber tackifier allows it to be used in a wide range of applications, making it a valuable additive in the production of high-performance rubber products across various industries. As industries continue to innovate and develop new applications for rubber materials, the demand for PTOP as a tackifier is expected to grow, driving further advancements in production techniques and quality control measures. Overall, the usage of PTOP in the Global Rubber Tackifier Market is characterized by its ability to enhance the performance and reliability of rubber products, making it an essential additive in a wide range of applications.

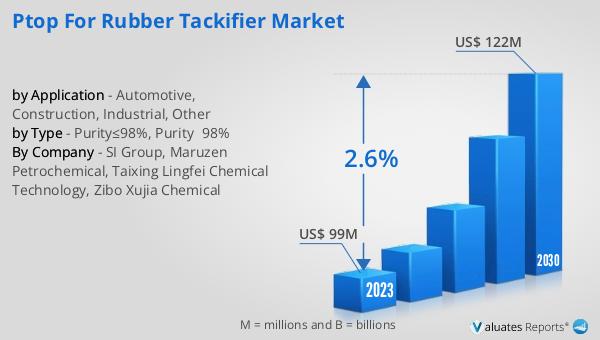

Global PTOP for Rubber Tackifier Market Outlook:

In 2023, the Global PTOP for Rubber Tackifier Market was valued at approximately US$ 99 million. This market is projected to experience growth over the coming years, with expectations to reach around US$ 122 million by 2030. This anticipated growth reflects a compound annual growth rate (CAGR) of 2.6% during the forecast period from 2024 to 2030. The steady growth of this market can be attributed to the increasing demand for high-performance rubber products across various industries, including automotive, construction, and industrial manufacturing. As these industries continue to evolve and innovate, the need for advanced materials that offer superior performance and sustainability is driving the demand for PTOP as a rubber tackifier. The market's growth is also influenced by regulatory frameworks and environmental considerations, prompting manufacturers to explore eco-friendly alternatives and production methods. Despite the moderate growth rate, the Global PTOP for Rubber Tackifier Market remains a vital segment within the broader chemical industry, supporting the development of advanced rubber products that meet the stringent requirements of modern applications. As the market continues to expand, manufacturers are expected to focus on innovation and quality control to meet the evolving needs of end-users and maintain a competitive edge in the industry.

| Report Metric | Details |

| Report Name | PTOP for Rubber Tackifier Market |

| Accounted market size in 2023 | US$ 99 million |

| Forecasted market size in 2030 | US$ 122 million |

| CAGR | 2.6% |

| Base Year | 2023 |

| Forecasted years | 2024 - 2030 |

| by Type |

|

| by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | SI Group, Maruzen Petrochemical, Taixing Lingfei Chemical Technology, Zibo Xujia Chemical |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |