What is Medical Polycarbonate Film - Global Market?

Medical polycarbonate film is a specialized material used extensively in the healthcare industry due to its unique properties. This film is made from polycarbonate, a type of plastic known for its strength, transparency, and resistance to heat and impact. These characteristics make it ideal for various medical applications where durability and clarity are essential. The global market for medical polycarbonate film is driven by the increasing demand for advanced medical devices and equipment. As healthcare systems worldwide continue to evolve, there is a growing need for materials that can withstand rigorous sterilization processes and provide reliable performance in critical applications. Medical polycarbonate film meets these requirements, making it a preferred choice for manufacturers. Additionally, the film's versatility allows it to be used in a wide range of products, from surgical instruments to diagnostic equipment, further fueling its market growth. The ongoing advancements in medical technology and the rising focus on patient safety and infection control are expected to continue driving the demand for medical polycarbonate film globally. As a result, the market is poised for significant growth in the coming years, with manufacturers investing in research and development to enhance the film's properties and expand its applications.

Below 15 μm, 15 - 30 μm, 30 - 60 μm, Above 60 μm in the Medical Polycarbonate Film - Global Market:

Medical polycarbonate films are categorized based on their thickness, which plays a crucial role in determining their suitability for various applications. Films below 15 μm are typically used in applications where flexibility and transparency are paramount. These ultra-thin films are often employed in medical sensors and diagnostic devices, where they provide a protective layer without compromising the device's sensitivity or performance. Their lightweight nature also makes them ideal for use in wearable medical devices, which require materials that do not add bulk or weight. In contrast, films with a thickness ranging from 15 to 30 μm offer a balance between flexibility and durability. These films are commonly used in applications that require a bit more robustness, such as in the production of medical labels and packaging. The added thickness provides enhanced protection against environmental factors, ensuring that the contents remain sterile and safe for use. Films in the 30 to 60 μm range are designed for applications that demand higher strength and impact resistance. These films are often used in the manufacturing of medical equipment housings and components, where they provide structural support and protection against physical damage. Their increased thickness also makes them suitable for use in applications that require repeated sterilization, as they can withstand the harsh conditions without degrading. Finally, films above 60 μm are the thickest and most durable, making them ideal for heavy-duty applications. These films are used in the production of medical trays, containers, and other equipment that require maximum strength and durability. Their robust nature ensures that they can withstand the rigors of daily use in medical settings, providing reliable performance over time. The choice of film thickness is determined by the specific requirements of the application, with manufacturers selecting the appropriate thickness to ensure optimal performance and longevity. As the demand for advanced medical devices continues to grow, the market for medical polycarbonate films of varying thicknesses is expected to expand, with manufacturers developing new formulations to meet the evolving needs of the healthcare industry.

Surgical Instruments, Implants, IV Connectors, Other in the Medical Polycarbonate Film - Global Market:

Medical polycarbonate film is widely used in various areas of the healthcare industry due to its unique properties. In the realm of surgical instruments, these films provide a protective layer that enhances the durability and longevity of the tools. The film's resistance to heat and chemicals ensures that the instruments can withstand repeated sterilization processes without degrading, making them a reliable choice for surgical applications. Additionally, the film's transparency allows for easy inspection of the instruments, ensuring that they remain in optimal condition for use. In the field of implants, medical polycarbonate film is used to create biocompatible coatings that enhance the performance and safety of the devices. The film's strength and flexibility allow it to conform to the shape of the implant, providing a protective barrier that reduces the risk of infection and improves the overall biocompatibility of the device. This makes it an ideal choice for use in a wide range of implants, from orthopedic devices to cardiovascular stents. For IV connectors, medical polycarbonate film provides a durable and reliable solution that ensures the safe and efficient delivery of fluids and medications. The film's resistance to cracking and breaking ensures that the connectors remain intact during use, reducing the risk of leaks and contamination. Additionally, the film's transparency allows for easy monitoring of the fluid flow, ensuring that the connectors function as intended. Beyond these specific applications, medical polycarbonate film is also used in a variety of other medical devices and equipment. Its versatility and durability make it a preferred choice for manufacturers looking to create high-quality, reliable products that meet the stringent requirements of the healthcare industry. From diagnostic equipment to protective barriers, the film's unique properties make it an essential component in the production of a wide range of medical products. As the demand for advanced medical devices continues to grow, the use of medical polycarbonate film is expected to increase, with manufacturers exploring new applications and developing innovative solutions to meet the evolving needs of the healthcare industry.

Medical Polycarbonate Film - Global Market Outlook:

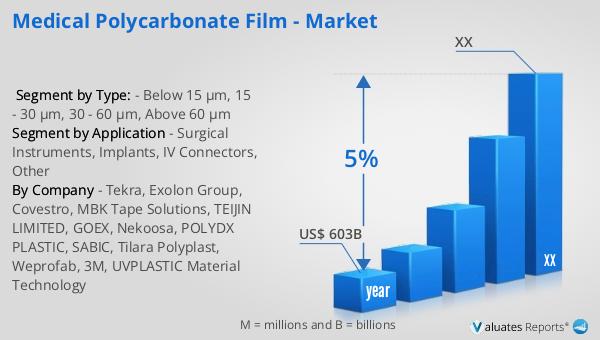

Our research indicates that the global market for medical devices is valued at approximately $603 billion in 2023. This market is projected to experience a compound annual growth rate (CAGR) of 5% over the next six years. This growth is driven by several factors, including the increasing demand for advanced medical technologies and the rising focus on improving patient outcomes. As healthcare systems worldwide continue to evolve, there is a growing need for innovative medical devices that can address complex medical conditions and improve the quality of care. The market's expansion is also supported by advancements in medical technology, which are enabling the development of new and improved devices that offer enhanced performance and reliability. Additionally, the increasing prevalence of chronic diseases and the aging population are contributing to the growing demand for medical devices, as these factors drive the need for more effective and efficient healthcare solutions. As a result, the global medical device market is expected to continue its upward trajectory, with manufacturers investing in research and development to create cutting-edge products that meet the evolving needs of the healthcare industry. This growth presents significant opportunities for companies operating in the medical device sector, as they seek to capitalize on the expanding market and deliver innovative solutions that improve patient care and outcomes.

| Report Metric | Details |

| Report Name | Medical Polycarbonate Film - Market |

| Accounted market size in year | US$ 603 billion |

| CAGR | 5% |

| Base Year | year |

| Segment by Type: |

|

| Segment by Application |

|

| By Region |

|

| By Company | Tekra, Exolon Group, Covestro, MBK Tape Solutions, TEIJIN LIMITED, GOEX, Nekoosa, POLYDX PLASTIC, SABIC, Tilara Polyplast, Weprofab, 3M, UVPLASTIC Material Technology |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |