What is Global MoS2-based Dry Film Lubricant Market?

Global MoS2-based dry film lubricant market refers to the worldwide industry focused on the production and distribution of lubricants that utilize molybdenum disulfide (MoS2) as a primary component. MoS2 is a compound known for its excellent lubricating properties, particularly in environments where traditional liquid lubricants may not perform well. These dry film lubricants are applied as a thin layer on surfaces to reduce friction and wear, enhancing the performance and longevity of machinery and components. The market encompasses various sectors, including industrial, aerospace, automotive, and oil and gas, where the demand for reliable and efficient lubrication solutions is critical. The global market is driven by the increasing need for high-performance lubricants that can withstand extreme temperatures, pressures, and environmental conditions. As industries continue to seek ways to improve efficiency and reduce maintenance costs, the adoption of MoS2-based dry film lubricants is expected to grow. This market is characterized by ongoing research and development efforts to enhance the properties of these lubricants and expand their applications across different sectors. Companies operating in this market are focused on innovation and strategic partnerships to meet the evolving needs of their customers.

Liquid, Spray in the Global MoS2-based Dry Film Lubricant Market:

In the global MoS2-based dry film lubricant market, liquid and spray forms are two prevalent methods of application, each offering unique advantages and catering to different industrial needs. Liquid-based MoS2 lubricants are typically used in situations where a more controlled and precise application is required. These lubricants are often applied using brushes or rollers, allowing for a uniform coating on surfaces. The liquid form is particularly beneficial in applications where intricate machinery or components are involved, as it can easily reach and coat complex geometries. This form of lubricant is also advantageous in environments where a thicker film is necessary to provide adequate protection against wear and friction. On the other hand, spray-based MoS2 lubricants offer a convenient and efficient method of application, especially in large-scale industrial settings. The spray form allows for quick and even distribution of the lubricant over large surface areas, making it ideal for use in manufacturing plants and assembly lines. This method is also beneficial in situations where access to the machinery or components is limited, as the spray can reach areas that may be difficult to coat using traditional methods. Additionally, spray-based lubricants are often preferred in applications where a thin, even layer is sufficient to provide the necessary lubrication and protection. Both liquid and spray forms of MoS2-based dry film lubricants are designed to offer superior performance in harsh environments. They are capable of withstanding extreme temperatures, pressures, and corrosive conditions, making them suitable for use in a wide range of industries. The choice between liquid and spray forms often depends on the specific requirements of the application, including the size and complexity of the components, the operating conditions, and the desired thickness of the lubricant film. In the industrial sector, MoS2-based dry film lubricants are used to enhance the performance and longevity of machinery and equipment. They are applied to reduce friction and wear, minimize maintenance costs, and improve overall efficiency. In the aerospace industry, these lubricants are used to protect critical components from extreme temperatures and pressures, ensuring the safe and reliable operation of aircraft. In the automotive industry, MoS2-based dry film lubricants are used to improve the performance and durability of engines, transmissions, and other components. In the oil and gas industry, these lubricants are used to protect equipment from harsh environmental conditions and extend the lifespan of critical components. Overall, the global MoS2-based dry film lubricant market is driven by the increasing demand for high-performance lubrication solutions that can withstand challenging operating conditions. As industries continue to seek ways to improve efficiency and reduce maintenance costs, the adoption of MoS2-based dry film lubricants is expected to grow. Companies operating in this market are focused on innovation and strategic partnerships to meet the evolving needs of their customers.

Industrial, Aerospace, Automobile, Oil and Gas, Others in the Global MoS2-based Dry Film Lubricant Market:

The global MoS2-based dry film lubricant market finds extensive usage across various sectors, including industrial, aerospace, automotive, oil and gas, and others, each benefiting from the unique properties of these lubricants. In the industrial sector, MoS2-based dry film lubricants are crucial for maintaining the efficiency and longevity of machinery and equipment. They are applied to reduce friction and wear, which in turn minimizes maintenance costs and downtime. Industries such as manufacturing, mining, and construction rely heavily on these lubricants to ensure the smooth operation of their machinery, even under extreme conditions. The aerospace industry also benefits significantly from MoS2-based dry film lubricants. These lubricants are used to protect critical components of aircraft from extreme temperatures and pressures encountered during flight. They help in reducing friction and wear on parts such as landing gear, engines, and control systems, ensuring the safe and reliable operation of aircraft. The lightweight nature of dry film lubricants also contributes to fuel efficiency, making them an attractive choice for the aerospace sector. In the automotive industry, MoS2-based dry film lubricants are used to enhance the performance and durability of engines, transmissions, and other components. They help in reducing friction and wear, leading to improved fuel efficiency and reduced emissions. These lubricants are also used in the production of automotive parts, where they provide a protective coating that enhances the longevity and reliability of components. The oil and gas industry relies on MoS2-based dry film lubricants to protect equipment from harsh environmental conditions. These lubricants are used in drilling operations, pipelines, and refineries to reduce friction and wear, extend the lifespan of critical components, and improve overall efficiency. The ability of MoS2-based lubricants to withstand extreme temperatures and pressures makes them ideal for use in this industry. Beyond these sectors, MoS2-based dry film lubricants are also used in other applications, such as electronics, where they provide a protective coating for sensitive components. They are also used in the production of consumer goods, where they enhance the performance and durability of products. Overall, the global MoS2-based dry film lubricant market is driven by the increasing demand for high-performance lubrication solutions that can withstand challenging operating conditions. As industries continue to seek ways to improve efficiency and reduce maintenance costs, the adoption of MoS2-based dry film lubricants is expected to grow. Companies operating in this market are focused on innovation and strategic partnerships to meet the evolving needs of their customers.

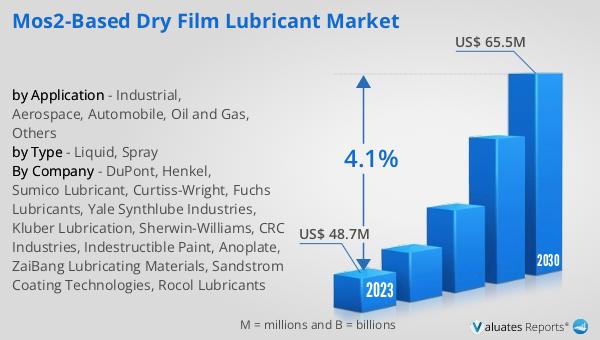

Global MoS2-based Dry Film Lubricant Market Outlook:

The global MoS2-based dry film lubricant market was valued at approximately $48.7 million in 2023, and it is projected to grow to around $65.5 million by 2030. This growth is expected to occur at a compound annual growth rate (CAGR) of 4.1% during the forecast period from 2024 to 2030. This market outlook highlights the increasing demand for MoS2-based dry film lubricants across various industries, driven by their superior performance in reducing friction and wear, even under extreme conditions. The projected growth reflects the ongoing need for high-performance lubrication solutions that can enhance the efficiency and longevity of machinery and components. As industries continue to seek ways to improve operational efficiency and reduce maintenance costs, the adoption of MoS2-based dry film lubricants is anticipated to rise. Companies operating in this market are likely to focus on innovation and strategic partnerships to meet the evolving needs of their customers and capitalize on the growth opportunities in this expanding market. The market outlook underscores the importance of MoS2-based dry film lubricants in various sectors, including industrial, aerospace, automotive, and oil and gas, where reliable and efficient lubrication solutions are critical for optimal performance.

| Report Metric | Details |

| Report Name | MoS2-based Dry Film Lubricant Market |

| Accounted market size in 2023 | US$ 48.7 million |

| Forecasted market size in 2030 | US$ 65.5 million |

| CAGR | 4.1% |

| Base Year | 2023 |

| Forecasted years | 2024 - 2030 |

| by Type |

|

| by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | DuPont, Henkel, Sumico Lubricant, Curtiss-Wright, Fuchs Lubricants, Yale Synthlube Industries, Kluber Lubrication, Sherwin-Williams, CRC Industries, Indestructible Paint, Anoplate, ZaiBang Lubricating Materials, Sandstrom Coating Technologies, Rocol Lubricants |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |