What is Global Alumina Monohydrate Market?

The Global Alumina Monohydrate Market is a significant segment within the broader chemical industry, focusing on the production and distribution of alumina monohydrate. This compound, also known as aluminum hydroxide, is primarily used as a precursor in the manufacturing of aluminum metal. It is derived from bauxite ore and is a crucial component in various industrial applications. The market for alumina monohydrate is driven by its extensive use in the production of aluminum, which is a vital material in industries such as automotive, aerospace, construction, and packaging. Additionally, alumina monohydrate is utilized in water treatment processes, as a flame retardant, and in the pharmaceutical industry for its antacid properties. The demand for alumina monohydrate is influenced by factors such as the growth of end-use industries, technological advancements in production processes, and environmental regulations. As industries continue to expand and innovate, the global alumina monohydrate market is expected to experience steady growth, driven by its diverse applications and the increasing demand for aluminum products worldwide.

Minimum Sodium Content: 50-100PPm, Minimum Sodium Content: Less than 50PPm in the Global Alumina Monohydrate Market:

In the Global Alumina Monohydrate Market, the sodium content is a critical factor that influences the quality and application of the product. Alumina monohydrate with a minimum sodium content of 50-100 parts per million (PPM) is often preferred for applications where higher purity levels are not as critical. This range of sodium content is suitable for general industrial applications where the presence of sodium does not significantly impact the performance or quality of the end product. On the other hand, alumina monohydrate with a minimum sodium content of less than 50 PPM is highly sought after for applications requiring high purity levels. This low sodium content is crucial in industries such as electronics, pharmaceuticals, and high-performance ceramics, where even trace amounts of impurities can affect the functionality and reliability of the final product. The production of low-sodium alumina monohydrate involves advanced purification processes to ensure that the sodium content is minimized, thereby enhancing the quality and performance of the material. The choice between these two sodium content levels depends on the specific requirements of the application and the desired properties of the final product. As industries continue to demand higher quality materials, the market for low-sodium alumina monohydrate is expected to grow, driven by its superior performance and versatility in high-tech applications.

Adhesive, Catalyst Carrier, Other in the Global Alumina Monohydrate Market:

The Global Alumina Monohydrate Market finds extensive usage in various applications, including adhesives, catalyst carriers, and other industrial processes. In the adhesive industry, alumina monohydrate is used as a filler and thickening agent, enhancing the adhesive properties and providing stability to the formulation. Its ability to improve the viscosity and mechanical strength of adhesives makes it an essential component in the production of high-performance adhesives used in construction, automotive, and packaging industries. As a catalyst carrier, alumina monohydrate plays a crucial role in the chemical industry. It provides a stable and inert surface for the dispersion of active catalytic materials, enhancing the efficiency and selectivity of chemical reactions. This application is particularly important in the production of petrochemicals, where alumina monohydrate-based catalysts are used to optimize processes such as cracking and reforming. Additionally, alumina monohydrate is used in other applications, including water treatment, flame retardants, and pharmaceuticals. In water treatment, it acts as a coagulant, helping to remove impurities and improve water quality. As a flame retardant, it is used in plastics and textiles to enhance fire resistance. In the pharmaceutical industry, alumina monohydrate is used as an antacid, providing relief from heartburn and indigestion. The versatility and effectiveness of alumina monohydrate in these applications make it a valuable material in various industrial processes, driving its demand in the global market.

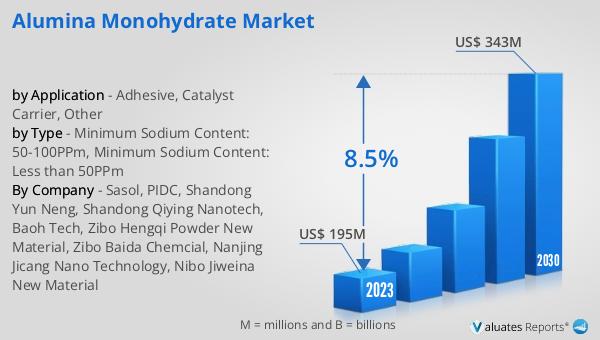

Global Alumina Monohydrate Market Outlook:

The outlook for the Global Alumina Monohydrate Market indicates a promising growth trajectory. In 2023, the market was valued at approximately US$ 195 million, reflecting its significant role in various industrial applications. Looking ahead, the market is projected to reach around US$ 343 million by 2030, demonstrating a robust compound annual growth rate (CAGR) of 8.5% during the forecast period from 2024 to 2030. This growth is attributed to the increasing demand for alumina monohydrate in diverse sectors such as automotive, aerospace, construction, and pharmaceuticals. The rising need for high-performance materials and the expansion of end-use industries are key factors driving this growth. Additionally, advancements in production technologies and the development of new applications are expected to further boost the market. As industries continue to evolve and innovate, the Global Alumina Monohydrate Market is poised to capitalize on these opportunities, offering significant potential for growth and development in the coming years.

| Report Metric | Details |

| Report Name | Alumina Monohydrate Market |

| Accounted market size in 2023 | US$ 195 million |

| Forecasted market size in 2030 | US$ 343 million |

| CAGR | 8.5% |

| Base Year | 2023 |

| Forecasted years | 2024 - 2030 |

| by Type |

|

| by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Sasol, PIDC, Shandong Yun Neng, Shandong Qiying Nanotech, Baoh Tech, Zibo Hengqi Powder New Material, Zibo Baida Chemcial, Nanjing Jicang Nano Technology, Nibo Jiweina New Material |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |